Process for producing high-concentration sodium nitrate brine through rotation dynamic leaching of nitratite ore

A technology of sodium nitrate and sodium nitrate, which is applied in the field of producing high-concentration sodium nitrate brine, can solve the problems of low leach solution concentration, high production cost, and low leaching yield, and achieve high leach solution concentration and low production cost , The effect of high leaching yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

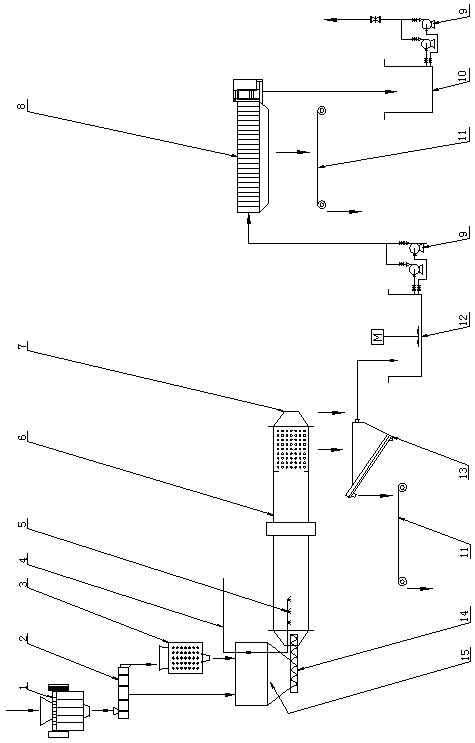

[0024] Embodiment 1: as figure 1 As shown, the collected sodium saltpeter raw ore is sent to the primary crusher 1 for crushing, and then sieved by the sieve 2 with an aperture of 50 mm. The pellets with a particle size of less than 50 mm enter the feed bin 15, and the pellets with a particle size larger than 50 mm enter the secondary crusher. The stage crusher 3 continues to crush until the particle size is less than 50mm, enters the feed bin 15, falls by itself, and is transported into the machine through the auger at the feeding port 14 of the TXH-1300 type digester 6. The middle and upper part of the 6 cavities of the digestion machine are connected with water pipes 4, and a plurality of shower heads 5 are installed on the pipes. According to the solid-to-liquid mass ratio of pellets:water of 1: 0.5-0.8, spray leaching water on the pellets. The leaching water can be added with normal temperature water such as sand washing water and circulating sodium nitrate brine. The lea...

Embodiment 2

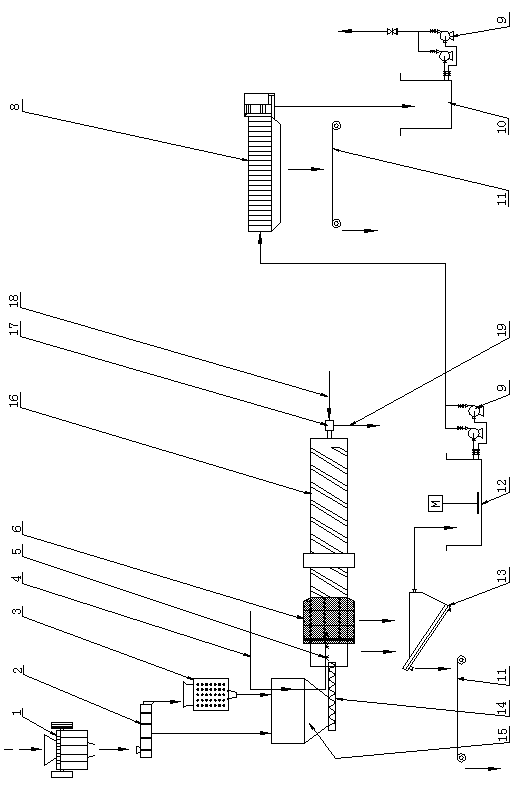

[0026] Embodiment 2: as figure 2 As shown, the collected sodium saltpeter raw ore is sent to the primary crusher 1 for crushing, and then sieved by the sieve 2 with an aperture of 50 mm. The pellets with a particle size of less than 50 mm enter the feed bin 15, and the pellets with a particle size larger than 50 mm enter the secondary crusher. The stage crusher 3 continues to crush until the particle size is less than 50mm, then enters the material bin 15, falls by itself, and is transported into the inside the furnace. The middle and upper part of the furnace cavity is connected with a water pipe 4, and a plurality of shower heads 5 are installed on the pipe. According to the solid-to-liquid mass ratio of pellets:water of 1:0.3-0.5, spray leaching water on the pellets, which can be added with normal temperature water such as sand washing water and circulating sodium nitrate brine. At the same time, through the steam pipe 18 and the steam shaft 17 on the right side of the r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com