PVC water-proof coiled material

A waterproofing membrane and PVC material technology, applied in building thermal insulation materials, roofing with flexible materials, building components, etc. The effect of low cost and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically described below in conjunction with the accompanying drawings.

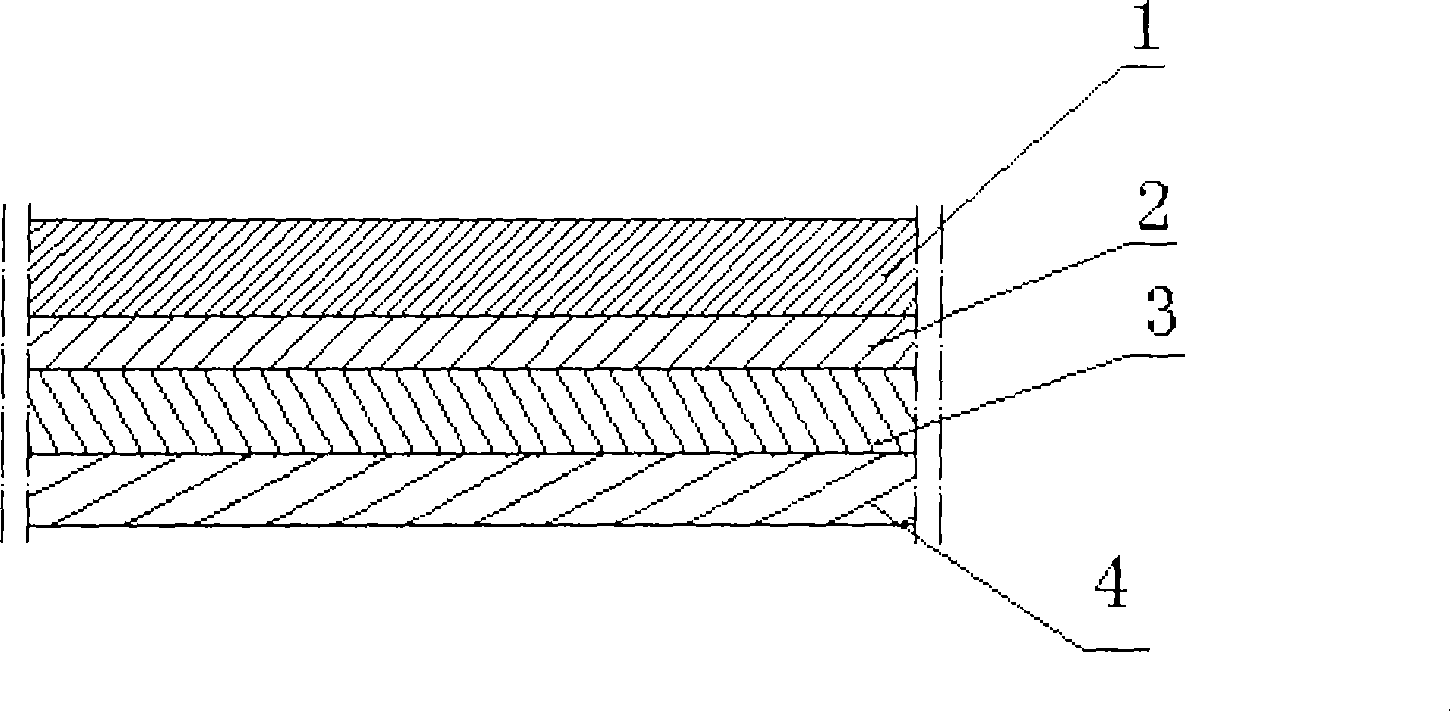

[0016] Accompanying drawing is the sectional structural drawing of PVC waterproof coiled material of the present invention.

[0017] The PVC waterproof membrane is composed of multiple layers, specifically, it is composed of a buffer layer 1, a PVC material layer 3, and a protective layer 4. The buffer layer 1 and the PVC material layer 3 are welded together by PVC gasket 2, and the protective layer is 4 points. Fixedly pasted on the PVC material layer 3. Among them, the buffer layer 1 and the protective layer 4 are high-quality polyester non-woven fabrics, which have the effect of isolation and protection, and greatly improve the anti-perforation ability of PVC coils; the special adhesive SLQ601 / SLQ801 is suitable for bonding between different base layers and different materials ; Unique Φ6.3mm high-strength screws can be directly fixed on the structural layer. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com