Recovery method and recovery device for waste carbon powder, and regenerated plastic thereof

A recovery device and recovery method technology, applied in separation methods, chemical instruments and methods, filter screens, etc., can solve problems such as environmental pollution, and achieve the effect of improving purity, avoiding flying everywhere, and collecting complete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1, a kind of waste toner recovery method, comprises the following steps:

[0026] (1) First, in a vacuum suction environment, disassemble the waste toner cartridge and waste toner cartridge, pour out the waste toner, and the waste toner will be sucked into a closed environment by vacuum suction, and will not be emitted into the surrounding atmosphere middle. Waste toner flows in a closed container, and the flowing toner is filtered to remove impurities such as screws with large particle sizes, plastic fragments, and other debris, and become purified waste toner;

[0027] (2) In a closed environment, use a fan or pump to form an air flow, and the waste toner that removes impurities and purifies flows in the air flow, and the powder filter mechanism that can only pass through the air but not the toner will flow with the air flow The waste toner is filtered out, and the filtered toner is collected and stored.

Embodiment 2

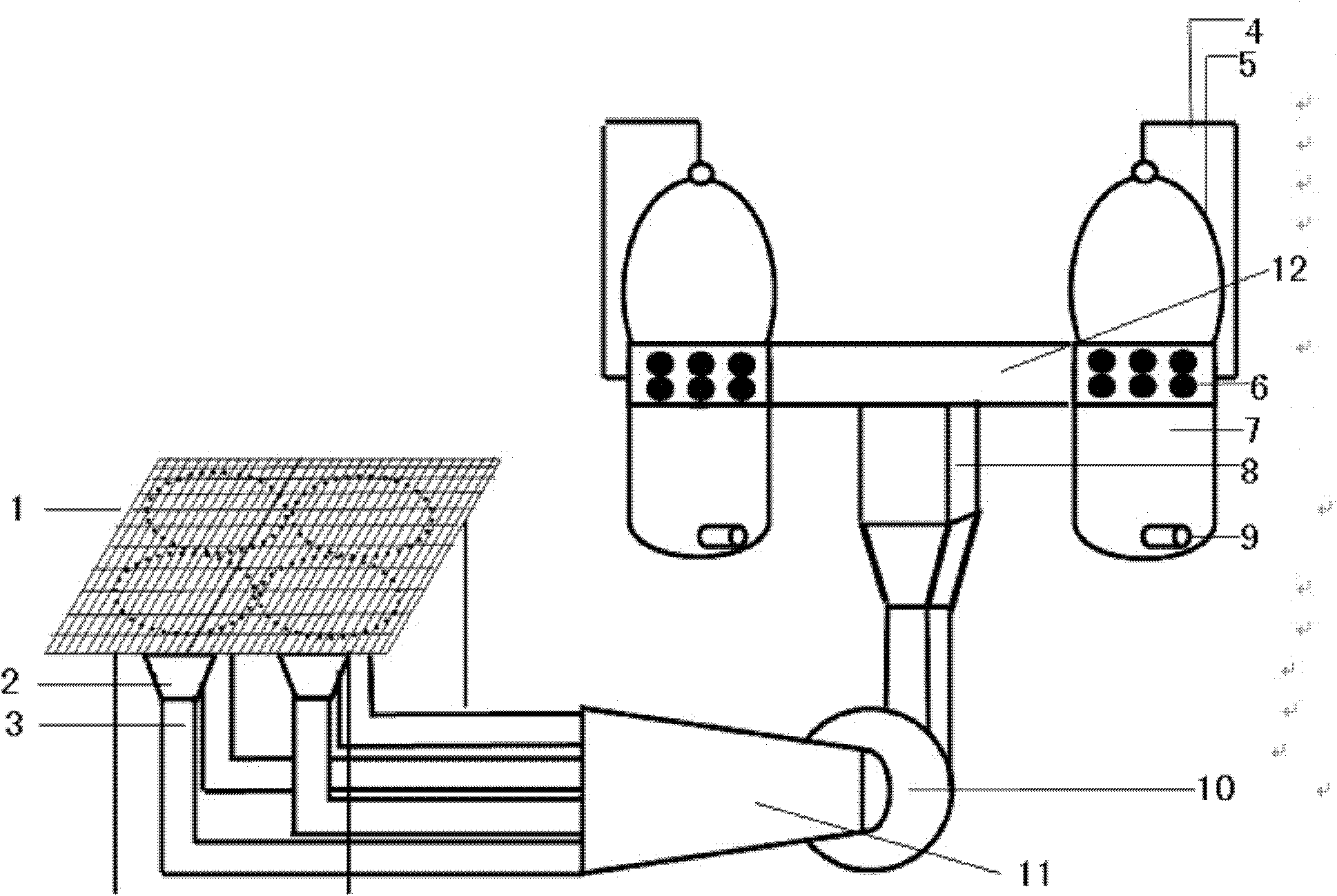

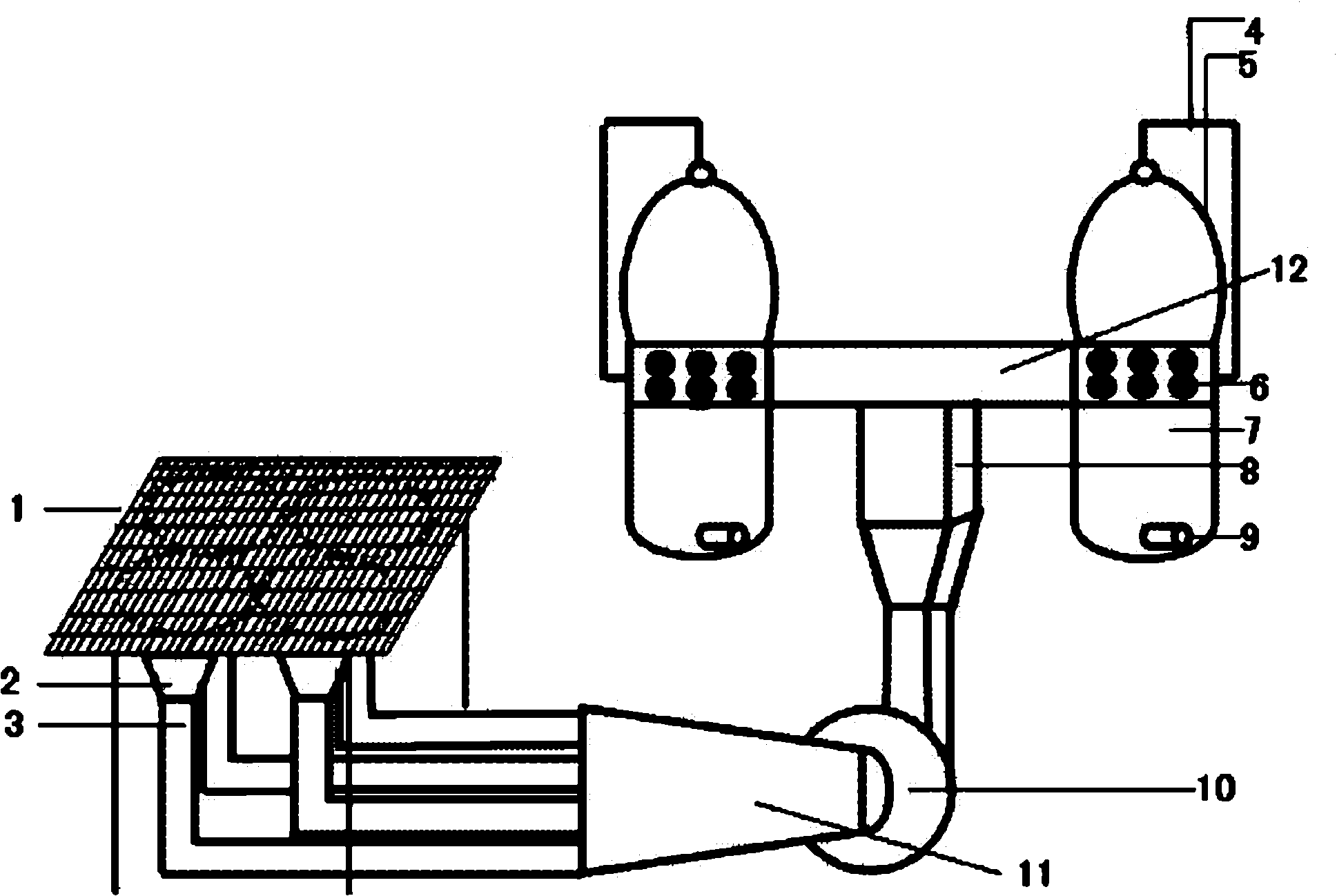

[0028] Embodiment 2, as figure 1 As shown, the waste toner recovery device includes an air cylinder 8, which is connected with an air extraction mechanism for twitching the flow of carbon powder, the front portion of the air cylinder 8 is provided with a filtering mechanism for filtering impurities, and the rear portion of the air cylinder 8 is provided with a filter for Exhaust filter mechanism and toner storage mechanism that can only discharge air impermeable toner.

[0029] The filter mechanism includes a filter cartridge 3. Since the waste toner cartridge and the toner cartridge are all waste, they may be mixed with many impurities, such as: screws, plastic fragments, other sundries and debris, waste carbon in the toner cartridge and the toner cartridge The powder may also be wet and agglomerated, so it is necessary to filter the raw material. A filter screen 1 is provided at the end of the filter cartridge 3 or at the front of the filter cartridge 3. In order to filter o...

Embodiment 3

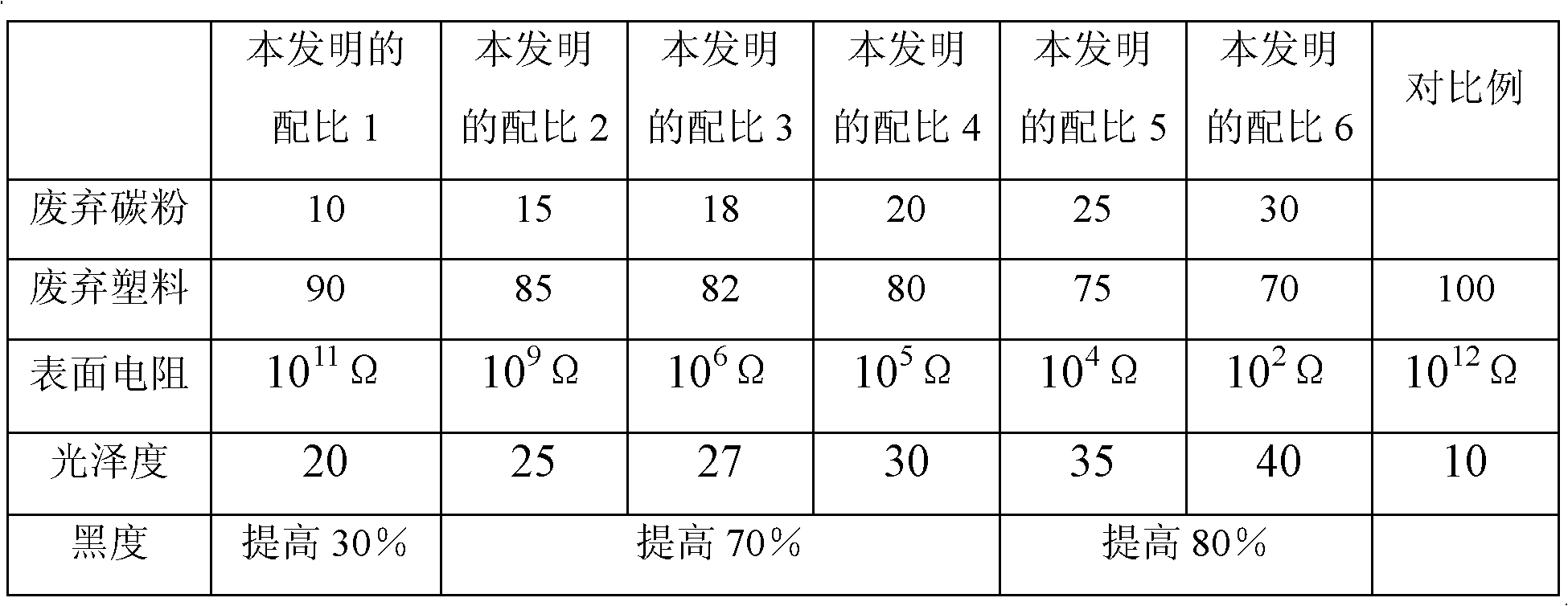

[0035] Embodiment 3, a kind of regenerated plastic, is to use the waste carbon powder recovered by the method of embodiment 1 or the waste carbon powder recovered by the device of embodiment 2 as raw material, and is made by cooperating with waste plastic, wherein the weight percentage of waste plastic is 70-90%, and the weight percentage of waste carbon powder is 10-30%. Concrete can adopt following proportioning (percentage by weight):

[0036]

[0037] In the above table, the surface resistance is tested with a hammer-type surface resistance tester, and the gloss is obtained by using a specular gloss meter to test the light reflectance of the material at a certain angle, and then compare it with the light reflectance of the standard plate . Blackness is determined by visual inspection.

[0038] It can be seen from the table that after adding waste toner, the performance of the recycled plastic has been greatly improved, and the gloss has been greatly improved compared ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com