Comprehensive recovering and environmentally-friendly recycling method of wasted three-way catalyst

A three-way catalyst and environmental protection technology, applied in the direction of improving process efficiency, etc., can solve problems such as backward recycling and refining technology, chaotic market order, low product purity, etc., achieve obvious advancement and cleanliness, improve environmental quality, and product purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

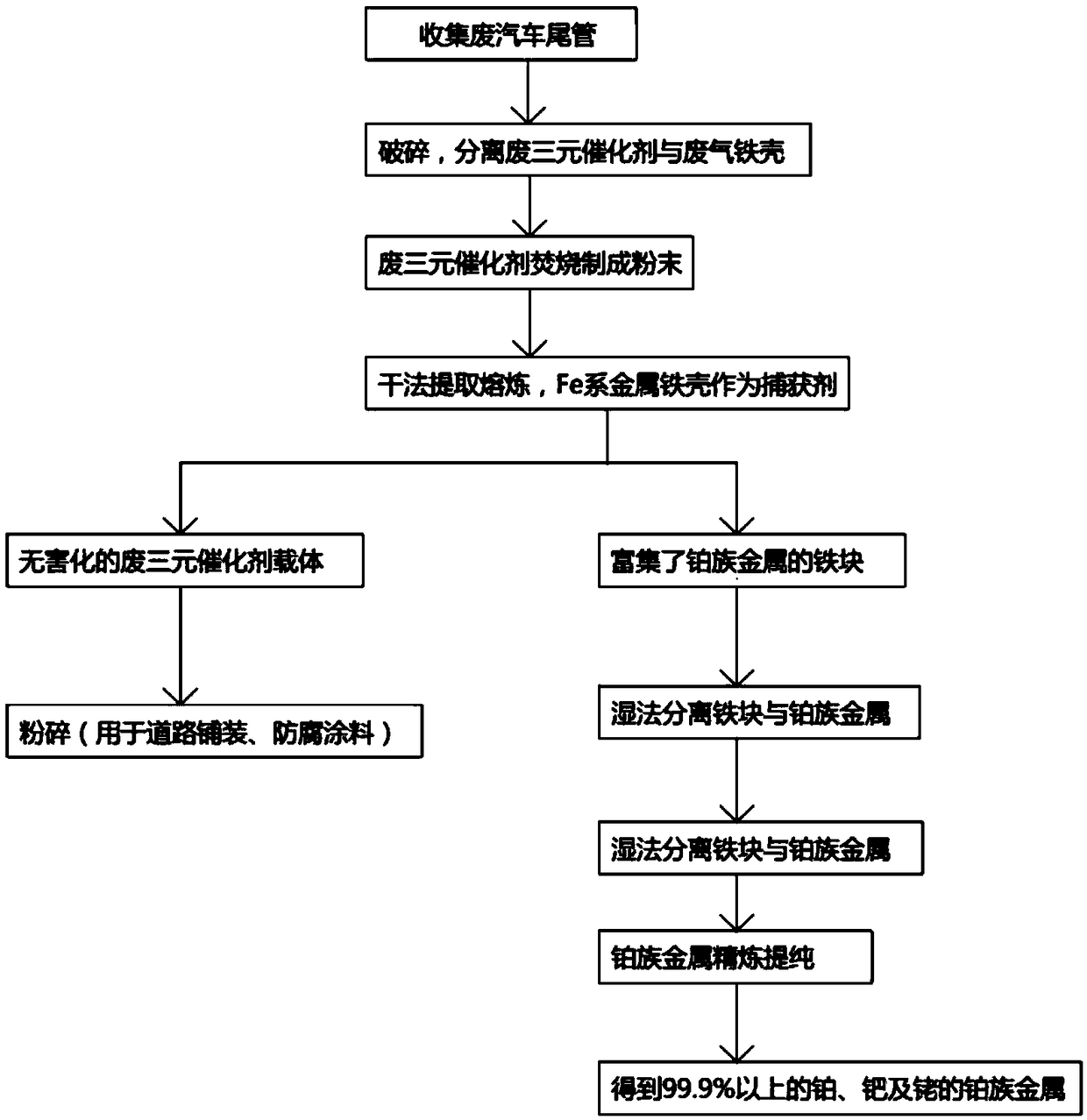

[0017] Such as figure 1 As shown, the waste three-way catalyst described in this embodiment 1 comprehensively recycles the method for environmental protection and recycling, comprising the following steps:

[0018] (1) Collect the exhaust pipes of waste automobiles with waste three-way catalysts, then crush them, and separate the waste three-way catalysts and waste iron shells;

[0019] (2) waste three-way catalyst is burned and made into powder;

[0020] (3) Carry out dry extraction and smelting of waste three-way catalyst powder, dry extraction and smelting adopts electric arc furnace smelting, adds Fe-based metal iron nuggets as a capture agent, and extracts and separates to form iron nuggets enriched with platinum group metals and harmless Chemicalized waste three-way catalyst carrier;

[0021] (4) Separating the iron block enriched with platinum group metals from the iron block and platinum group metals, and adopting the wet separation process of fractional extraction a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com