Environment-friendly technology for preparing ketoleucine calcium in aqueous phase

A technology of calcium ketoleucine and green process is applied in the field of pharmaceutical synthesis, which can solve the problems of flammability and explosiveness, many reaction steps, long steps, etc., and achieves the effects of solving pollution problems, good product quality and few reaction steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

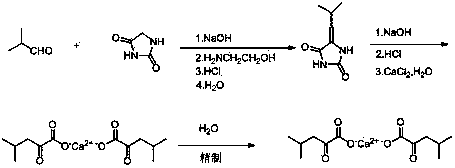

Method used

Image

Examples

Embodiment 1

[0035] Preparation of isobutylene hydantoin

[0036] Add 300kg of drinking water, 78kg of hydantoin, 5.0kg of 30% industrial liquid caustic soda and 9.0kg of monoethanolamine into the 1000L reactor. After the reaction solution was warmed up to be clear, 56 kg of isobutyraldehyde was slowly added dropwise to the reaction system. After dripping, keep refluxing for 8-12 hours, the reaction solution is cooled to room temperature, 36% hydrochloric acid is added dropwise to adjust the pH value to 5.0 (weakly acidic), after the addition, the reaction solution is slowly cooled to 8-10℃ And stir for 90 minutes. After the stirring, the material was filtered to obtain 123.6 kg of wet product. The wet product was dried to obtain 110.1 kg of isobutylene hydantoin, with a yield of 91.5%.

[0037] Preparation of ketoleucine calcium

[0038] Into the reactor, 240kg of drinking water and 267kg of 30% industrial liquid caustic soda were added in sequence. The reactor was replaced with vacuum nitro...

Embodiment 2

[0041] In the reactor, 220 kg of drinking water and 260 kg of 33% industrial liquid caustic soda were added in sequence. The reactor was replaced with vacuum nitrogen for three times and refluxed for 100 minutes under the protection of nitrogen. The temperature of the reaction liquid was lowered to 80°C, and 74.3 kg of isobutylene hydantoin was added to the reaction system. After adding, the temperature is raised to reflux, and the temperature is kept and refluxed for 90-100 minutes. Drop 76kg of 42% calcium chloride aqueous solution with mass concentration, keep stirring for 15min after adding, filter the material while it is hot, and collect the filtrate. The temperature of the filtrate was lowered to 55°C, 35% hydrochloric acid was added with a mass concentration, the pH value was adjusted to 2.0, and the vacuum nitrogen was replaced 2 to 3 times. Add 33% industrial liquid caustic soda to adjust the pH to 8.30 again. After cooling to 30°C, drop 89.2 kg of 42% calcium chlori...

Embodiment 3

[0044] Add 200kg of drinking water to the reaction kettle, and 260kg of 29% industrial liquid caustic soda with a mass concentration of 29%. The reaction kettle is replaced by vacuum nitrogen three times, and refluxed for 100min under nitrogen protection. After adding, heat up to reflux, keep reflux for 90-100min, add 81.8kg of 38% calcium chloride aqueous solution dropwise, keep and stir for 15min after adding, filter the material while it is hot, collect the filtrate; cool the filtrate to 50℃, slowly Add 34% hydrochloric acid with a mass concentration of hydrochloric acid to adjust the pH to 1.2, and vacuum nitrogen replacement for 2 to 3 times; add a mass concentration of 29% industrial liquid caustic soda to adjust the pH to 8.00, after cooling to 30°C, dropwise add a mass concentration of 38% chlorine 96kg of calcium chloride aqueous solution, after adding the heat preservation reaction for 60min, cooling to 8℃, keeping and stirring for 100min, filtering to obtain 76kg of c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com