FCC (Fluid Catalytic Cracking) gasoline oxidation desulphurization method based on molybdenum polyoxometallate

A polyoxometalate and oxidative desulfurization technology, which is applied in chemical instruments and methods, refining with oxygen-containing compounds, chemical/physical processes, etc., can solve the problems of complex synthesis process and difficult reaction control, and achieve low dosage, High stability, simple method effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1 FCC gasoline oxidative desulfurization method based on molybdenum polyoxometalate

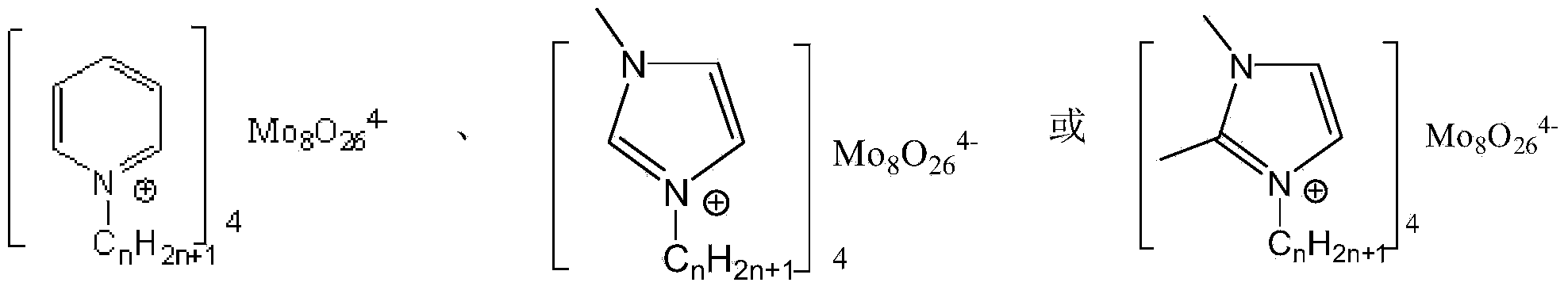

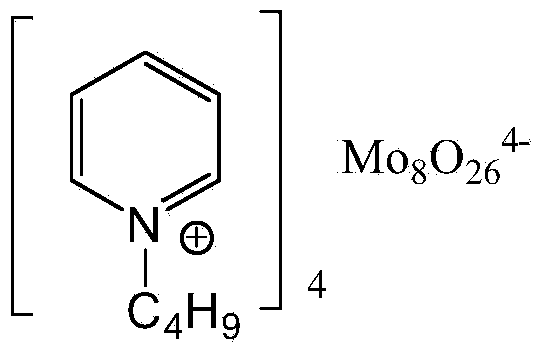

[0017] (1) Catalyst 1-butylpyridine molybdate ([C 4 py] 4 Mo 8 o 26 ) preparation

[0018] The structure of 1-butylpyridine molybdate is shown in the following formula:

[0019]

[0020] Its synthesis method is as follows:

[0021] (1) Add a certain amount of pyridine and n-butane bromide in a molar ratio of about 1:1.2 into a round-bottomed flask at room temperature. 2 Stir and react at 40°C for 1 hour in an oil bath under protection, then heat to 70°C and reflux for 12 hours to obtain the reaction intermediate product [C 4 py]Br, adding a mixture of acetonitrile and ethyl acetate (volume ratio: 1:2) for recrystallization, and then washing with n-hexane for 2 to 3 times, then distilling and drying with a rotary evaporator to obtain pure [C 4 py] Br intermediate;

[0022] (2) A certain amount of diluted [C 4 py]Br aqueous solution was exchanged through a cation e...

Embodiment 2

[0029]Embodiment 2 Based on the method for oxidative desulfurization of FCC gasoline of molybdenum polyoxometalate

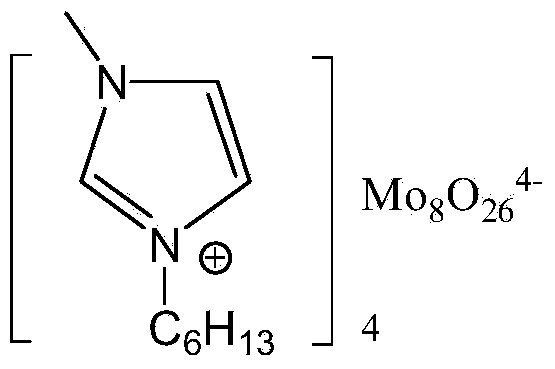

[0030] (1) Catalyst 1-hexyl-3-methylimidazolium molybdate ([C 6 mim] 4 Mo 8 o 26 ) preparation

[0031] The structure of 1-hexyl-3-methylimidazolium molybdate is shown in the following formula:

[0032]

[0033] Its synthesis method is as follows:

[0034] (1) Add a certain amount of N-methylimidazole and n-hexane bromide in a molar ratio of about 1:1.2 into a round-bottomed flask at room temperature. 2 Stir and react at 40°C for 1 hour in an oil bath under protection, then heat to 70°C and reflux for 12 hours to obtain the reaction intermediate product [C 6 mim]Br, to which a mixture of acetonitrile and ethyl acetate (1:2 by volume) was added for recrystallization, the obtained crystals were washed 2 to 3 times with n-hexane, and dried in vacuum to obtain pure [C 6 mim]Br intermediate;

[0035] (2) A certain amount of diluted [C 6 mim] Br aqueous so...

Embodiment 3

[0043] Embodiment 3 based on the method for oxidative desulfurization of FCC gasoline of molybdenum polyoxometalate

[0044] (1) Catalyst 1,2-dimethyl-3-ethylimidazolium molybdate ([C 2 dmim] 4 Mo 8 o 26 ) preparation

[0045]

[0046] Its preparation method is as follows:

[0047] (1) Add a certain amount of 1,2-dimethylimidazole to ethyl bromide in a molar ratio of about 1:1.2 into a round-bottomed flask at room temperature. 2 Stir and react at 40°C for 1 hour in an oil bath under protection, then heat to 70°C and reflux for 12 hours to obtain the reaction intermediate product [C 2 dmim]Br, recrystallized from a mixture of acetonitrile and ethyl acetate (volume ratio 1:2), washed 2 to 3 times with an appropriate amount of n-hexane, and distilled and dried by a rotary evaporator to obtain pure [C 2 dmim] Br intermediate;

[0048] (2) A certain amount of diluted [C 2 dmim]Br aqueous solution was exchanged through a cation exchange resin column, and the effluent solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com