Synthesis method for lithium iron phosphate/carbon composite material

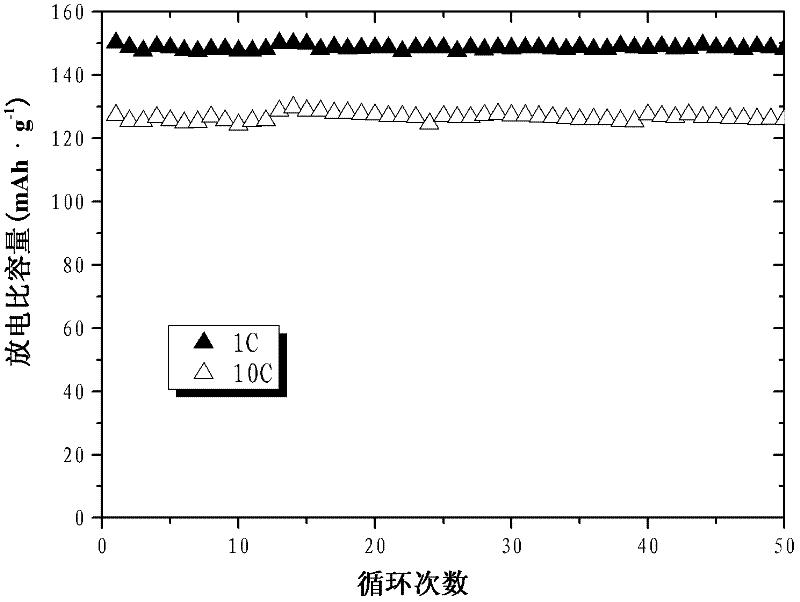

A technology of carbon composite materials and lithium iron phosphate, applied in electrical components, battery electrodes, circuits, etc., can solve the problem of low electron mobility of lithium iron phosphate, achieve high current and excellent cycle performance, high specific capacity, and simple process Feasible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 3.48gLi 3 PO 4 0.5H 2 O, 1.68g reduced iron powder, 9.33g FePO 4 4H 2 O, 0.2g lithium carbonate, 2.7g citric acid, mix well. Put it into a ball mill container and mill it for 3 hours, then put it in nitrogen and bake it at 750°C for 15 hours to get LiFePO with uniform particles. 4 / C powder.

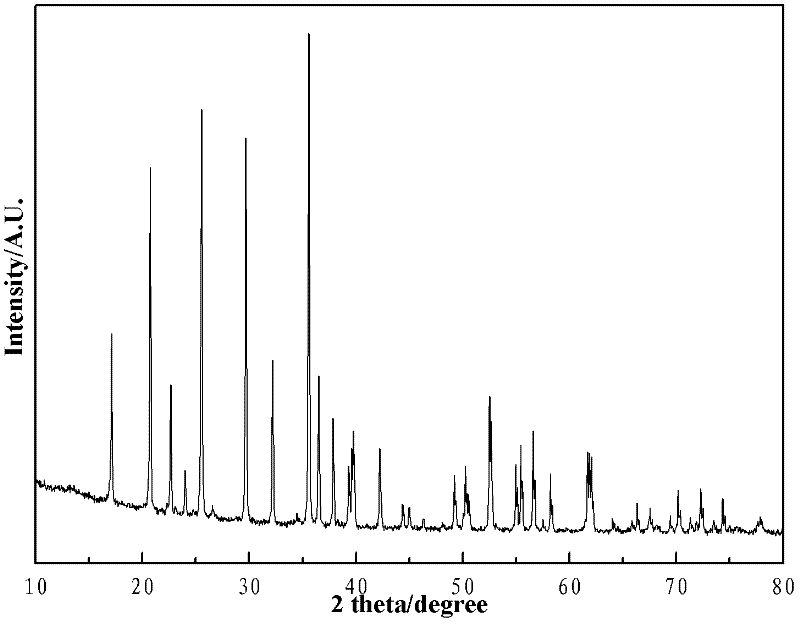

[0029] X-ray diffraction was done on the prepared lithium iron phosphate / carbon, by figure 1 It can be seen that the prepared lithium iron phosphate has an olivine-type orthorhombic pure phase structure, and there are no peaks of other impurities in the spectrum. figure 2 is LiFePO 4 / C powder magnified 10,000 times scanning electron microscope photo, it can be seen from the figure that the particle size of the product is about 1 micron.

[0030] The active material LiFePO 4 / C powder, acetylene black, and polyvinylidene fluoride in a mass ratio of 8:1:1, weigh a total of 0.5g, dissolve it in an appropriate amount of 1-methyl-2-pyrrolidone, mix it evenly, and apply...

Embodiment 2

[0033] Weigh 3.48gLi 3 PO 4 0.5H 2 O, 1.68g reduced iron powder, 9.33g FePO 4 4H 2 O, 0.17g lithium carbonate, 2.7g citric acid, mix well. Put it into a ball mill container and mill it for 3 hours, then put it in nitrogen and bake it at 750°C for 15 hours to get LiFePO with uniform particles. 4 / C powder.

Embodiment 3

[0035] Weigh 3.48gLi 3 PO 4 0.5H 2 O, 1.68g reduced iron powder, 9.33g FePO 4 4H 2 O, 0.27g lithium carbonate, 2.7g citric acid, mix well. Put it into a ball mill container and mill it for 3 hours, then put it in nitrogen and bake it at 750°C for 15 hours to get LiFePO with uniform particles. 4 / C powder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com