Livestock-raising automatic feeder

An automatic feeding and feed technology, applied in animal husbandry, poultry farming, chemical instruments and methods, etc., can solve the problems of reducing labor economic costs, high labor intensity, and manual participation, etc., to improve work efficiency and practicality Strengthen and reduce the effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

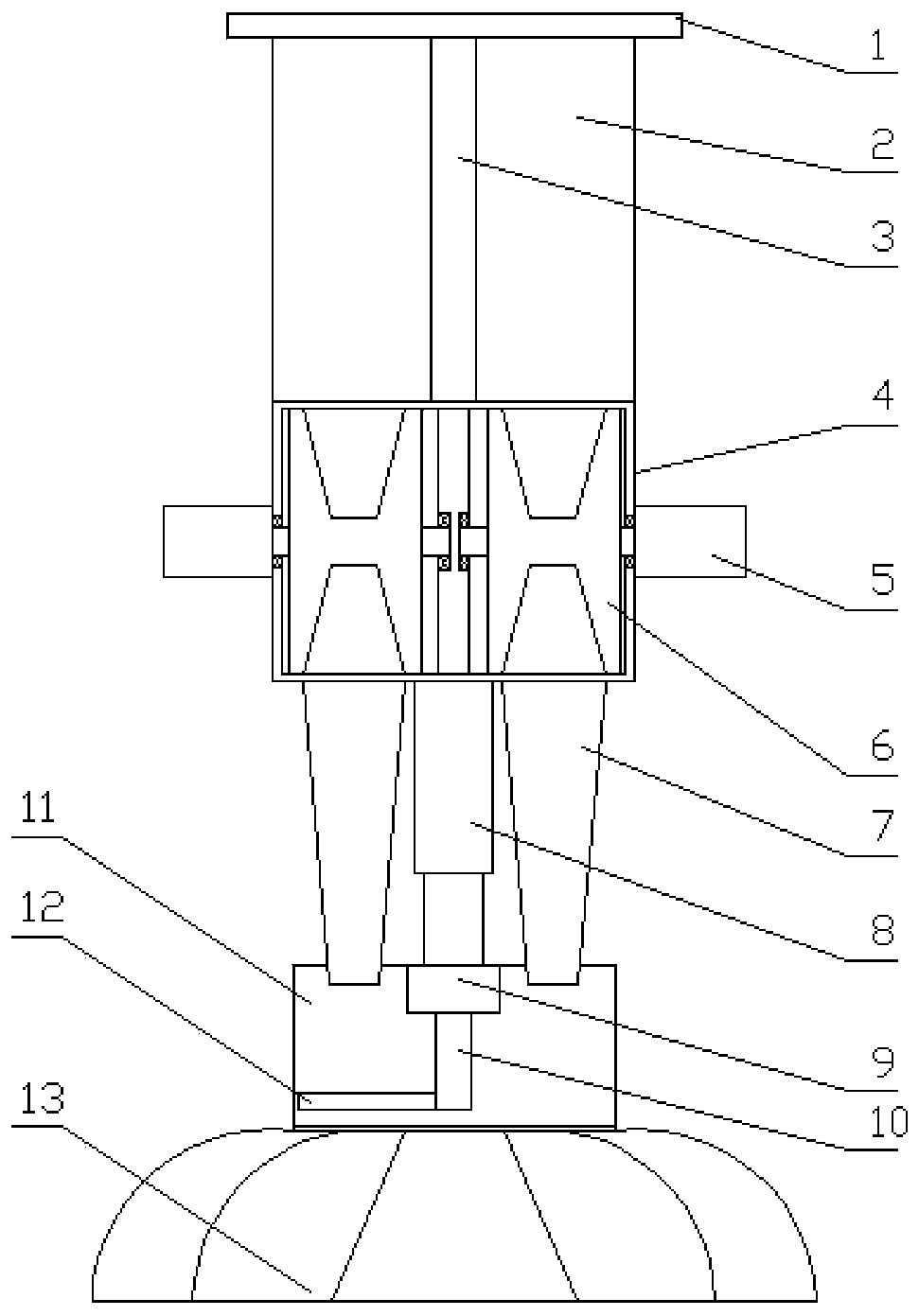

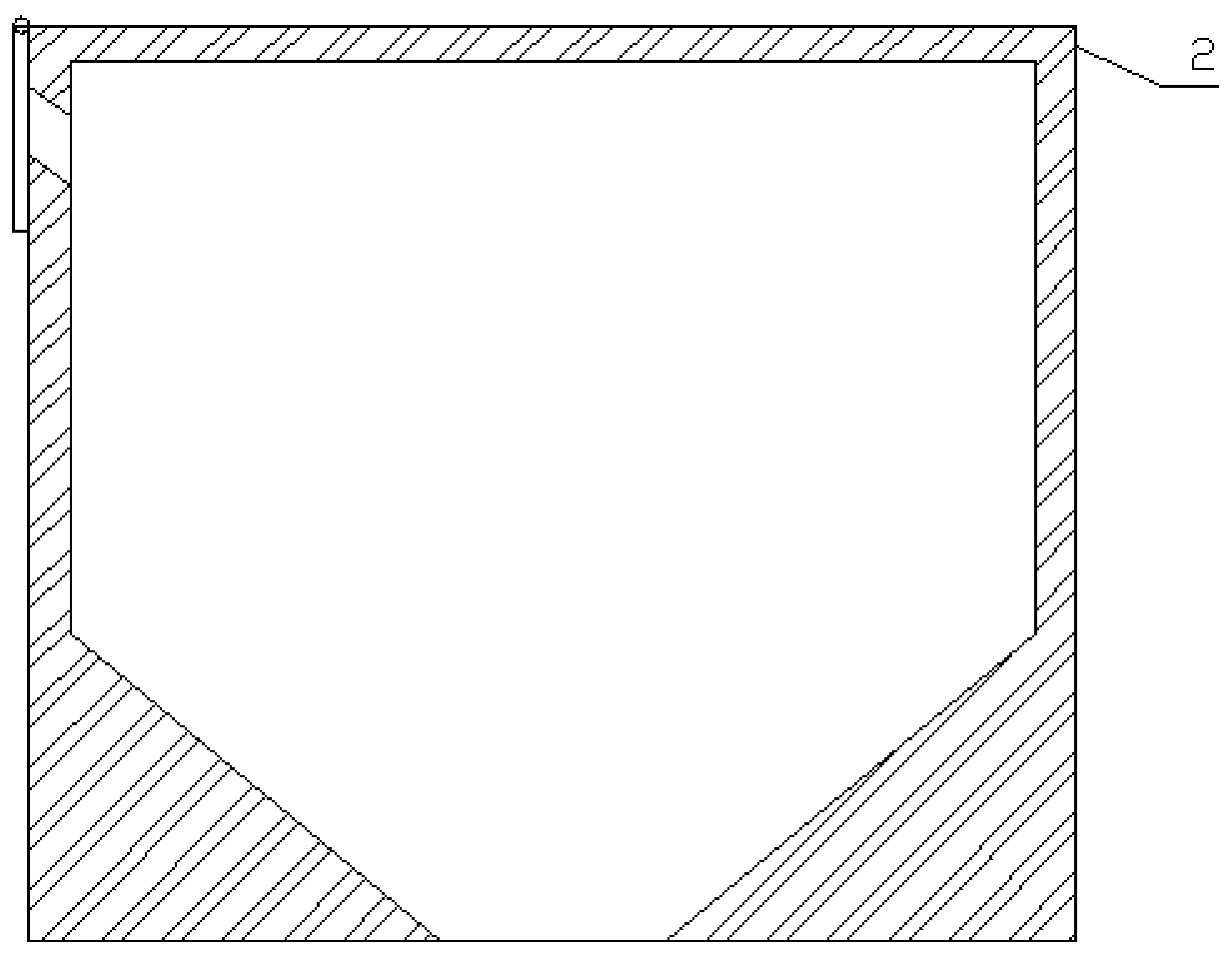

[0022] see figure 1 , The embodiment of the present invention provides an automatic feeder for animal husbandry, which includes a plurality of feed bins 2 for feeding, and feed can be placed in the feed bins 2 .

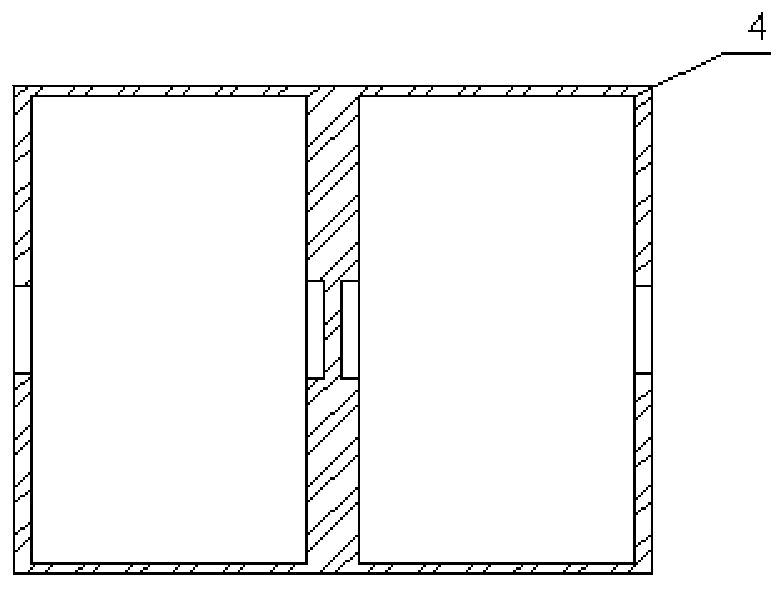

[0023] The bottom of the feed bin 2 is provided with a distribution assembly for quantitatively distributing various feeds. The distribution assembly includes at least two distribution devices arranged side by side and assembled together. The inlet of each distribution device is connected to one of the feed bins. The outlets of 2 are communicated in one-to-one correspondence, and a mixing device for mixing and stirring various feeds is arranged below the distribution assembly. The inlet of the mixing device communicates with the outlets of all distribution devices. Below is provided with the feed pan 13 that is used to contain the feed flowing out from the mixing device to facilitate the animals to eat.

[0024] Further, such as image 3 As shown, the distribution ...

Embodiment 2

[0041] As a further improvement on the basis of Example 1, this embodiment is provided with a height adjustment device 8 between the material distribution assembly and the mixing device, one end of the height adjustment device 8 is fixed to the distribution assembly, and the height The other end of the adjustment device 8 is fixed to the mixing device, and is used to adjust the height of the material tray 13 to meet the needs of different usage situations.

[0042] Further, the height adjusting device 8 is a vertically arranged multi-stage telescopic hydraulic cylinder, the cylinder body of the hydraulic cylinder is fixed to the bottom surface of the distribution assembly, and the end of the piston rod of the hydraulic cylinder is connected to the top of the box body 11. face fixed.

[0043] The present invention provides an automatic feeder for animal husbandry, through which different types of feed are regularly and quantitatively lowered to the mixing device for mixing thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com