High-capacity/high-first-effect red phosphorus-molecular sieve template carbon composite negative electrode material as well as preparation method and application thereof

A technology of negative electrode material and composite material, which is applied in the field of red phosphorus-molecular sieve template carbon composite negative electrode material and its preparation, can solve the problems of deterioration of battery cycle performance and low electrical conductivity, and achieves the effect of good electrical conductivity and avoiding volume effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

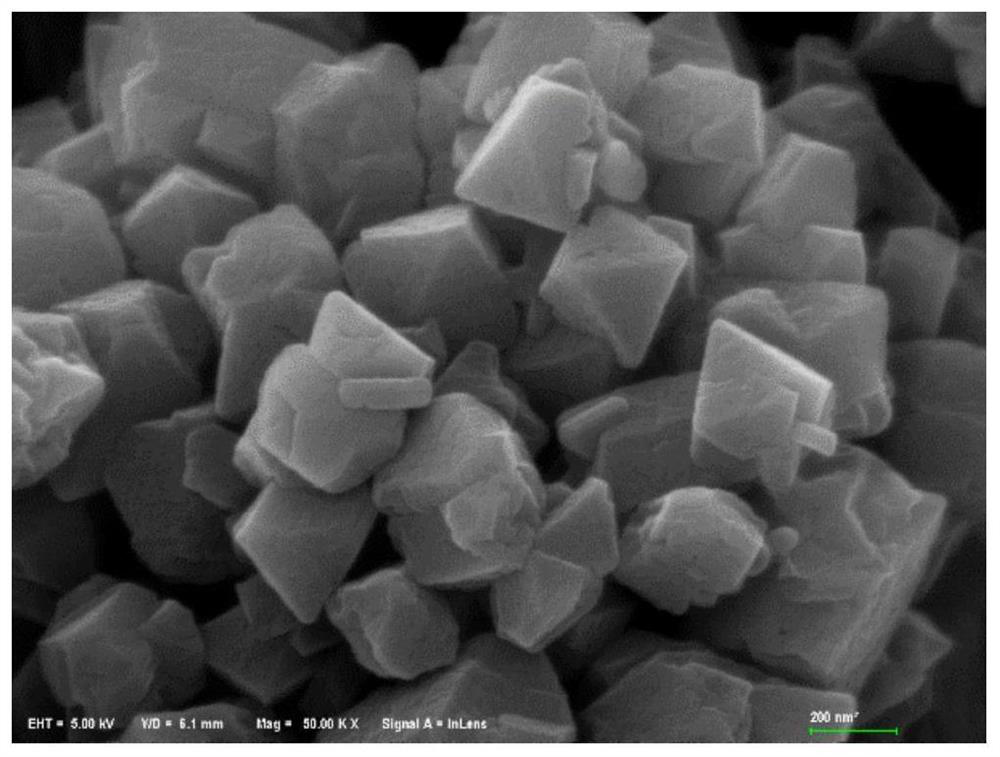

[0033] (1) Preparation of molecular sieve template carbon

[0034] Using 5g Y-type zeolite molecular sieve as a template, 50mL furfuryl alcohol was impregnated with 50mL furfuryl alcohol for 10h under vacuum at 350°C. Furfuryl alcohol was deposited and polymerized in the channel of zeolite molecular sieve, and the treated mixture was filtered to obtain polyfurfuryl alcohol / zeolite composite material. The composite material was put into the reactor, and the reactor was purged with argon, and kept at 80 °C for 24 h; then the reaction temperature was increased at 5 °C min -1 The heating rate was raised to 150°C and kept for 8h; then the reaction temperature was increased at 5°C min -1 The heating rate was increased to 700°C, the gas flow was switched to propylene, and the gas flow was switched to argon after 4 hours of vapor deposition, and the temperature was continued to rise to 900°C in an argon atmosphere, kept for 3 hours, and then naturally cooled to room temperature and th...

Embodiment 2

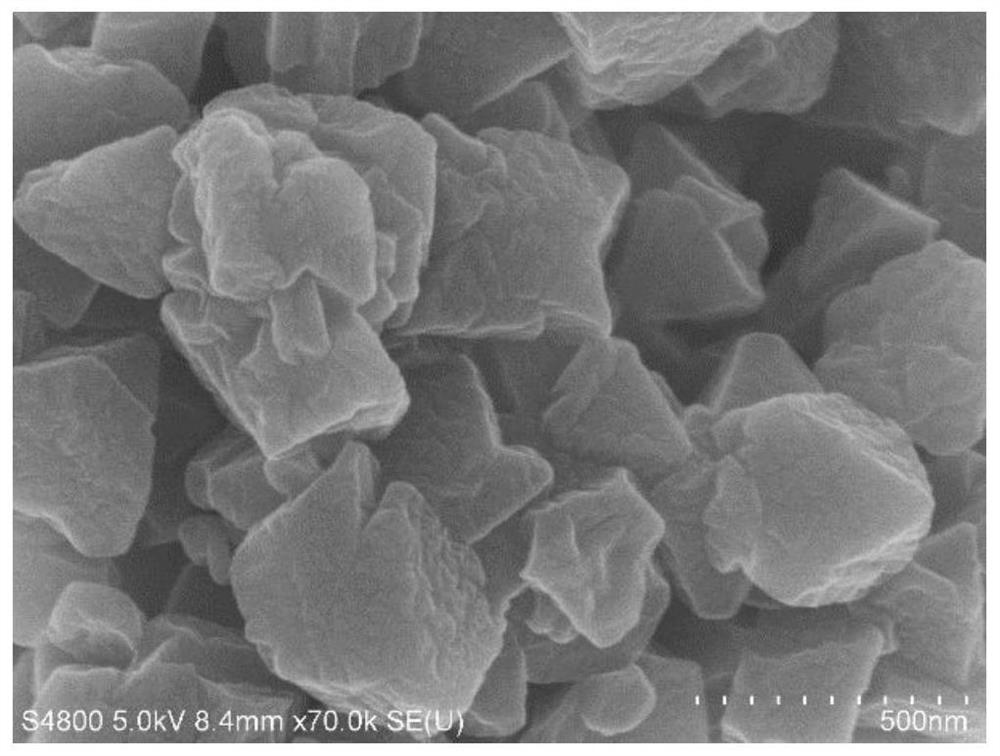

[0045] (1) Preparation of molecular sieve template carbon

[0046] Using 5g Y-type zeolite molecular sieve as a template, 50mL furfuryl alcohol was impregnated with 50mL furfuryl alcohol for 10h under vacuum at 350°C. Furfuryl alcohol was deposited and polymerized in the channel of zeolite molecular sieve, and the treated mixture was filtered to obtain polyfurfuryl alcohol / zeolite composite material. The composite material was put into the reactor, and the reactor was purged with argon, and kept at 80 °C for 24 h; then the reaction temperature was increased at 5 °C min -1 The heating rate was raised to 150°C and kept for 8h; then the reaction temperature was increased at 5°C min -1 The heating rate was increased to 800°C, the gas flow was switched to propylene, and the gas flow was switched to argon after 4 hours of vapor deposition, and the temperature was continued to rise to 900°C in an argon atmosphere, kept for 3 hours, and then naturally cooled to room temperature and th...

Embodiment 3

[0054] (1) Preparation of molecular sieve template carbon

[0055] The preparation process is the same as in Example 1.

[0056] (2) Preparation of red phosphorus-molecular sieve template carbon composites

[0057] The preparation process is the same as in Example 1.

[0058] (3) Preparation of red phosphorus-molecular sieve template carbon composite electrode

[0059] The preparation process is the same as in Example 1.

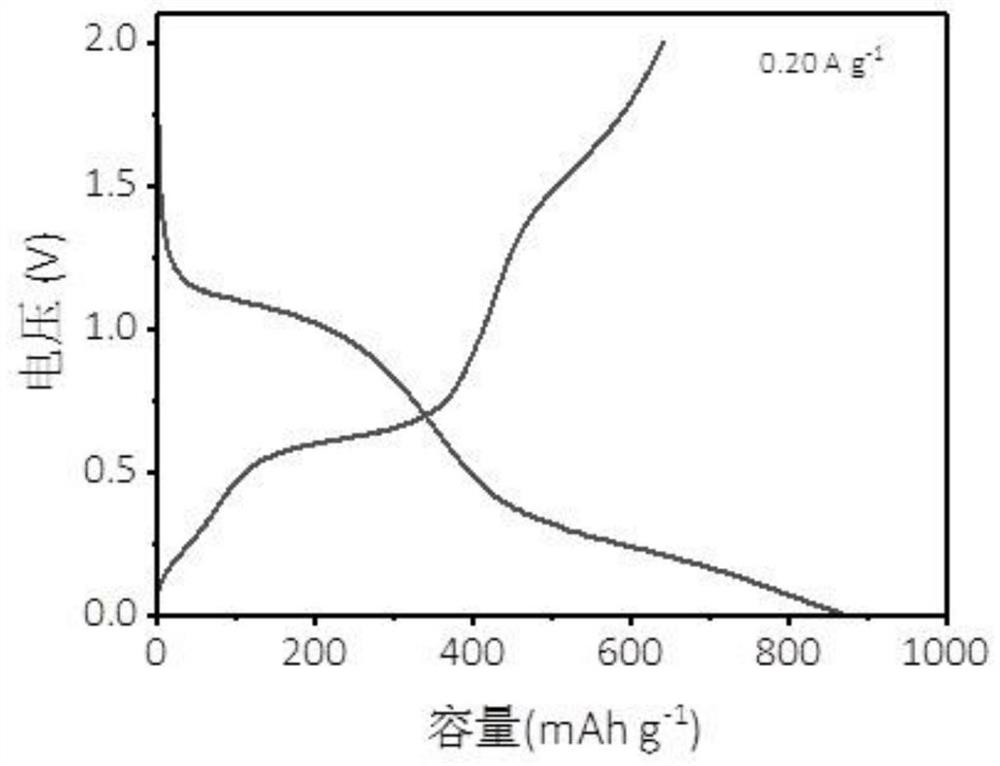

[0060] (4) Assembling sodium-ion batteries

[0061] The composite electrode prepared above is assembled with metal sodium in a glove box filled with argon to form a CR2032 sodium-ion battery, and the electrolyte of the sodium-ion battery is 1M NaClO 4 The PC / EC carbonate electrolyte is used, and the diaphragm is made of Glass fiber (Whatman).

[0062] Use the Wuhan Landian battery test system to conduct a constant current discharge test on the above-mentioned sodium-ion battery in a 30°C incubator, and the test current density of the sodium-ion battery ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com