Method for preparing SSZ-13 molecular sieve membrane through steam-assisted conversion

A molecular sieve and steam technology, used in molecular sieve compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of high pressure, unsafe, large amount, etc., and achieve the goal of improving synthesis repeatability, reducing solid waste and improving safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

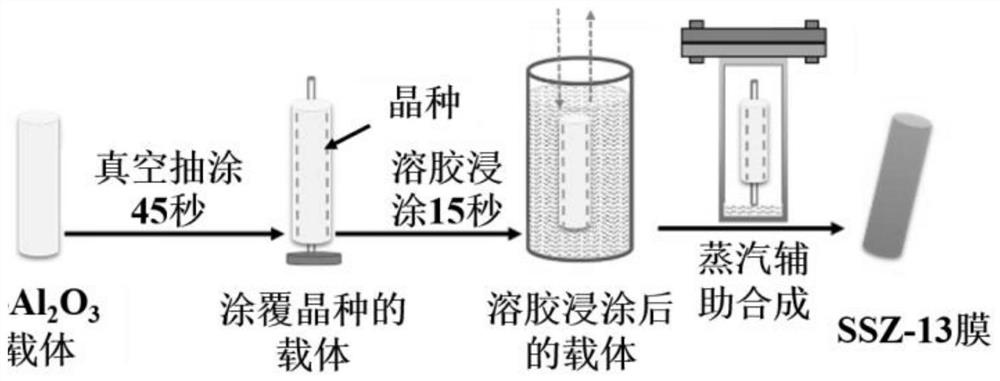

[0034] A kind of preparation method of the SSZ-13 molecular sieve membrane of steam assisted reforming, concrete steps are as follows:

[0035] (1) Preparation of SSZ-13 molecular sieve seed crystals:

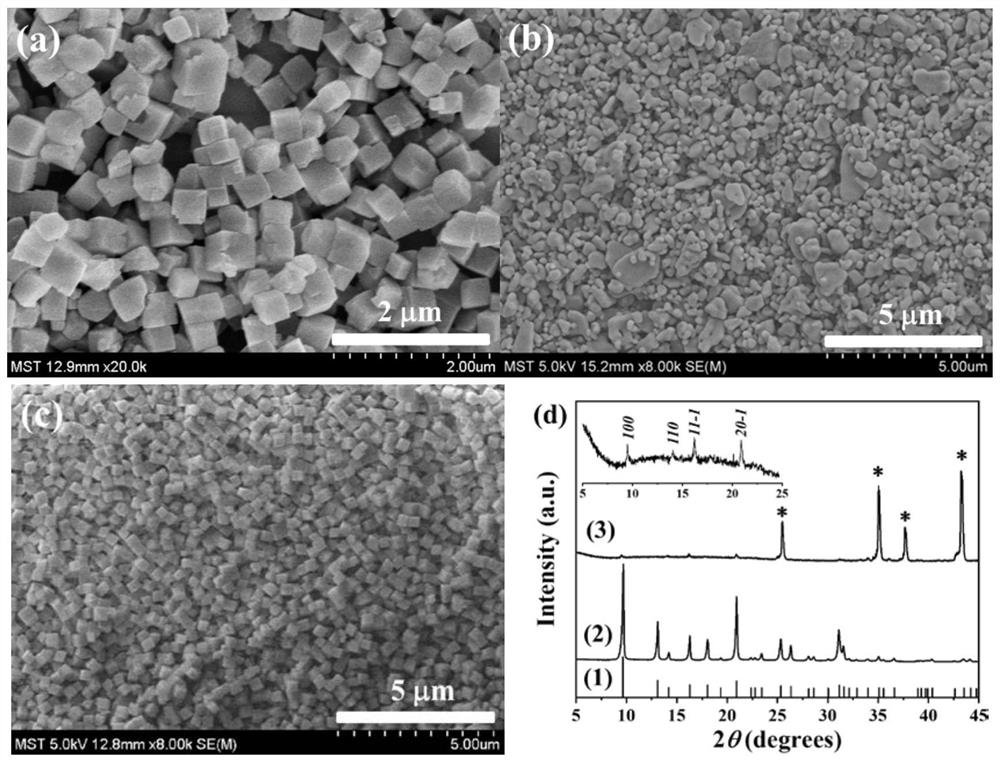

[0036] Sodium hydroxide (NaOH, 98%), N,N,N-trimethyl-1-adamantyl ammonium hydroxide (TMAdaOH, 25wt%, SDA), deionized water, aluminum hydroxide (Al(OH) 3 ,99%) and silica sol (TM-40,40%) mixed to obtain molecular sieve synthesis sol molar ratio is SiO 2 / Al 2 o 3 =200,Na 2 O / SiO 2 =0.1,H 2 O / SiO 2 = 44, TMAdaOH / SiO 2 = 0.4. After aging at room temperature for 8 hours, the reaction sol was poured into a stainless steel reactor with a Teflon lining, and reacted in an oven at 433K for 96 hours. The reaction product is washed with deionized water, centrifuged at high speed for 3-4 times, and finally the obtained solid molecular sieve particles are dried in a 373K oven.

[0037] (2) Pretreatment of porous supports:

[0038] Using a porous alumina tube as a support, add 0.1...

Embodiment 2

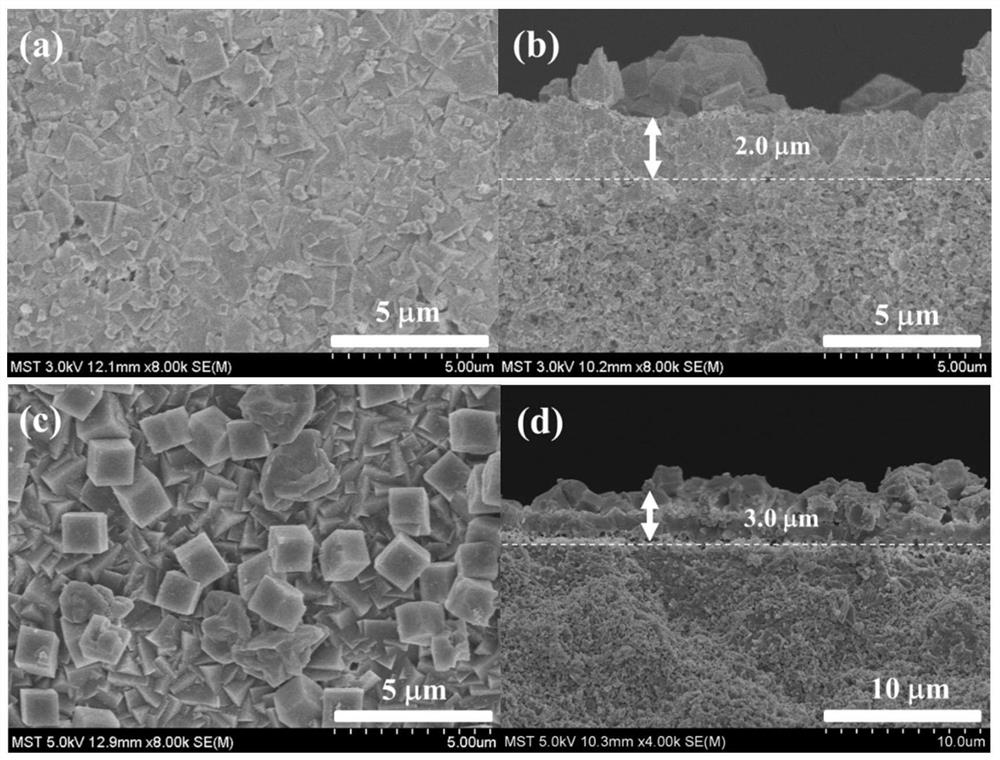

[0046] The preparation method of SSZ-13 molecular sieve film is basically the same as that of Example 1, wherein the preparation process of step (1) and (3) film and seed crystal is different in that the H in the synthetic sol 2 O / SiO 2 =20; the added amount of the sol for membrane synthesis is 1.0 g (1 vol% of the volume of the reaction kettle). The prepared film is marked as M2, and its SEM surface and cross-sectional images are shown in Figure 4 a and 4b. membrane M2 in N 2 / CH 4 The separation performance of the system is shown in Table 1.

Embodiment 3

[0048] The preparation method of molecular sieve film is basically the same as that of Example 1, wherein the difference in the preparation process of step (1) and (3) film and seed crystal is that the H of synthetic sol 2 O / SiO 2 =500, the sol was aged at room temperature for 24h. The prepared membrane is marked as M3, and its SEM surface and cross-section are as follows Figure 4 c and 4d are shown. membrane M3 in N 2 / CH 4 The separation performance of the system is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com