Method for preparing metallocene catalyst and application thereof in ethylene propylene rubber production

The technology of a metallocene catalyst and ethylene-propylene rubber is applied to the preparation of metallocene catalyst and its application in the production of ethylene-propylene rubber, which can solve the problems of low yield and low purity, and achieve high yield, high purity, The effect of low production cost

Inactive Publication Date: 2010-09-08

HENAN ACADEMY OF SCI CHEM RES INST CO LTD

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the synthesis of metallocene catalysts generally has the disadvantages of low yield and low purity. For this reason, to explore the synthesis method of metallocene catalysts, improve its yield and purity and apply it to the production of ethylene-propylene rubber, is of great help to improving the current ethylene-propylene rubber. The lack of rubber production technology is of great significance to promote the technological innovation of ethylene propylene rubber production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

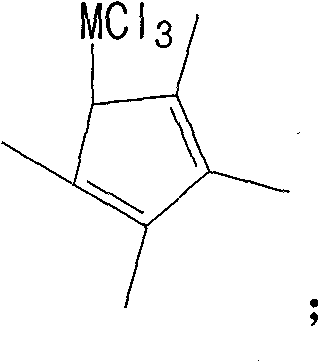

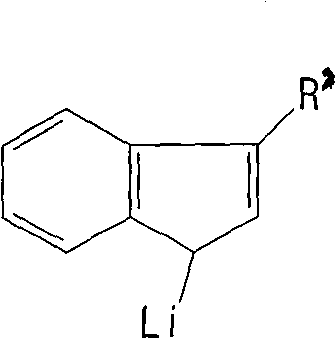

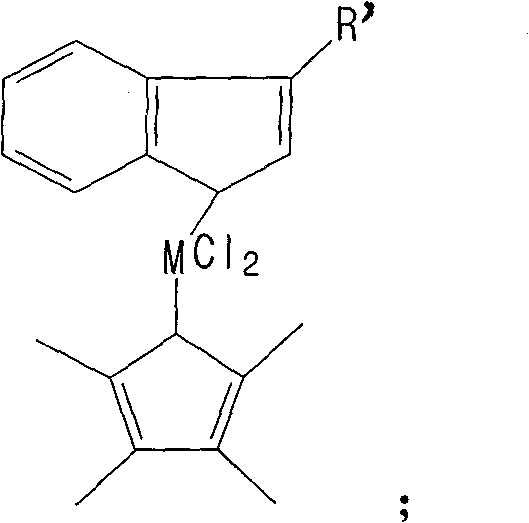

The invention discloses a preparation method of metallocene catalyst and an application in the production of ethylen-propylene rubber, wherein the preparation method comprises at 0-30 DEG C, under nitrogen gas protection, reacting tetramethyl cyclopentadienyl lithium with MCI4 at a mol ratio of 1 / 2 to prepare (C9H13) MCI3, at 0 to 30 DEG C, under nitrogen gas protection, reacting substituted undenyl ligand and (C9H13) MCI3 at a mol ratio of 1 / 1, to obtain [(C9H6R)(C9H13)]MCI2. The catalyst synthesis method has simple process, high yield, strong operability and benefit for industrial production. In the presence of a metallocene compound catalyst and a catalyst promoter as methylaluminoxane, ethane and propone can be used as main materials to be polymerized for 1-5h in toluene solution at 30 to 70 DEG C and under 1-10kg / cm2 pressure to prepare ethylen-propylene rubber, with simple polymerization process, low catalyst consumption and low production cost. Compared with the prior art, the invention reduces the pollution of vanadium catalyst, protects environment and develops a new route for ethylen-propylene rubber production.

Description

technical field The invention relates to the preparation and application of a catalyst, in particular to the preparation of a metallocene catalyst and its application in the preparation of ethylene-propylene rubber. Background technique Ethylene-propylene rubber (EPR) is a kind of copolymer rubber with ethylene and propylene as basic monomers, which came out after the invention of Ziegler-Natta catalyst and the appearance of polyethylene and polypropylene. It is divided into binary ethylene-propylene rubber (EPM) and There are two types of ethylene propylene diene monomer (EPDM). The former is a copolymer of ethylene and propylene; the latter is a copolymer of ethylene, propylene and a small amount of non-conjugated dienes, two commonly used non-conjugated dienes are ethylidene norbornene (ENB) and dicyclopentadiene (DCPD). Ethylene-propylene rubber has excellent ozone resistance, fire resistance, weather resistance, and anti-aging properties. In addition, the monomer is c...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08F210/16C08F4/642

Inventor 郭利兵张海洋李江涛蒋卫鹏韩兆海杨瑞娜傅鹏飞

Owner HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com