Preparation method and device for solar-grade polycrystalline silicon

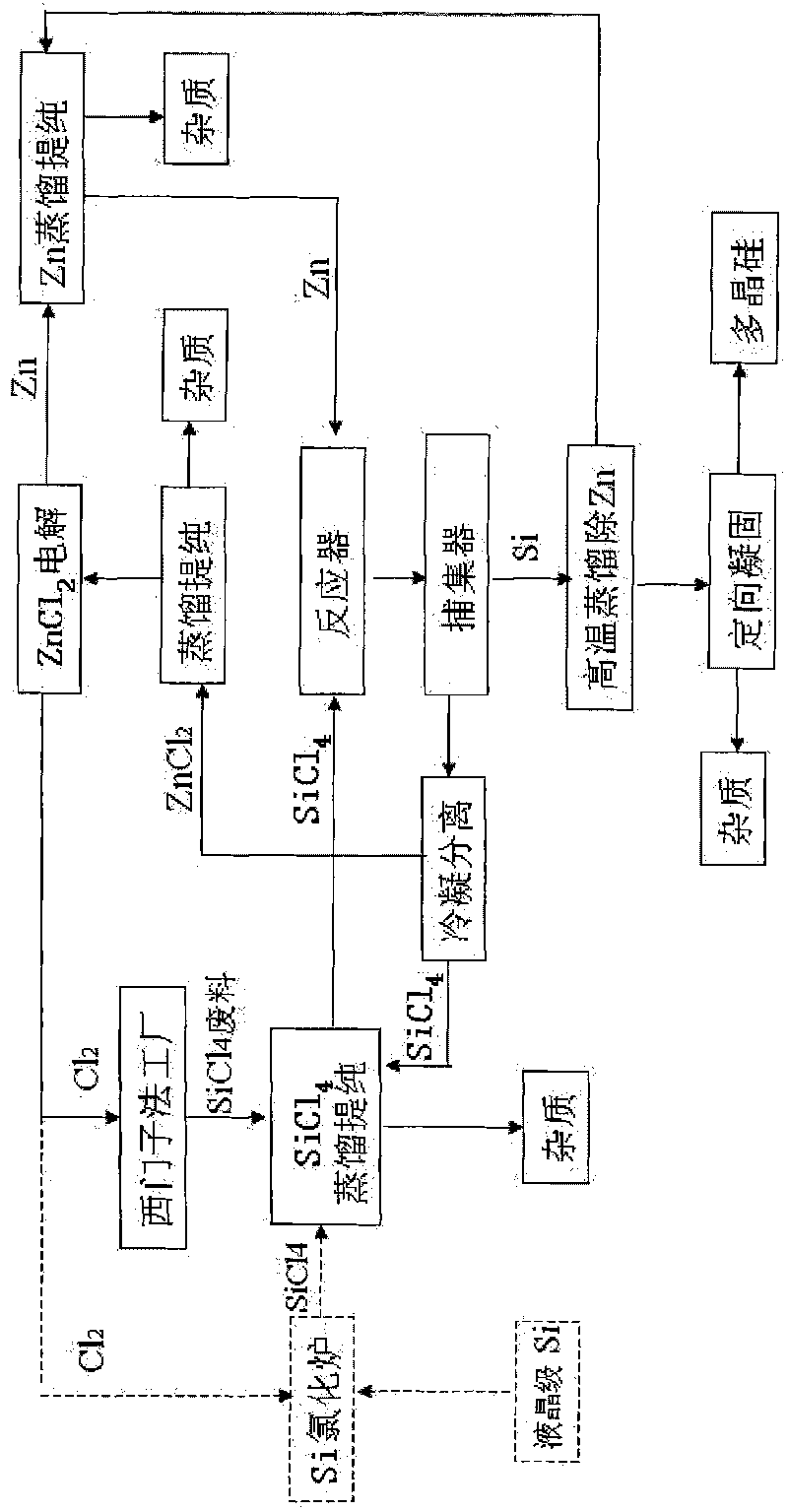

A solar-grade, preparation device technology, applied in the field of solar cells, can solve problems such as increased loss of polysilicon and zinc, difficulty in controlling the quality of reactants, and equipment corrosion, achieving high production efficiency, easy control of reactant ratios, and low production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

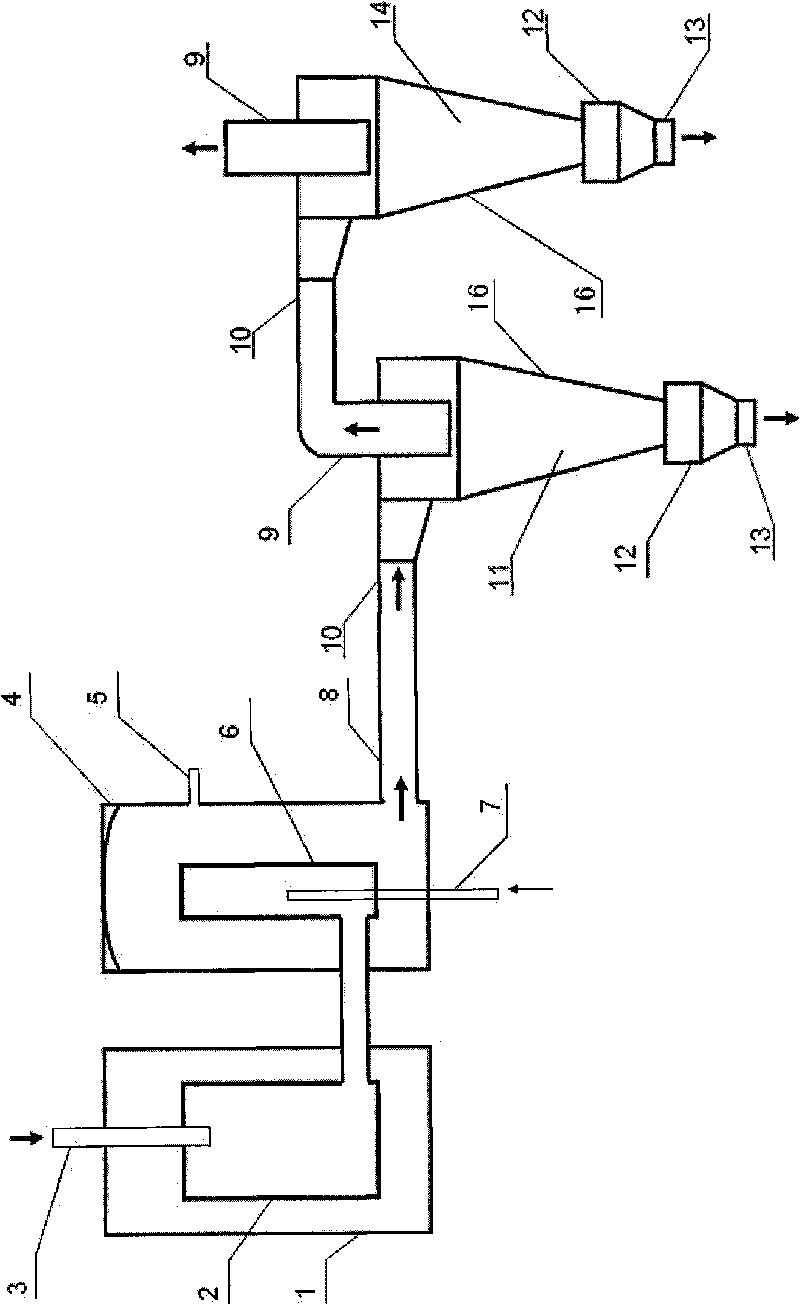

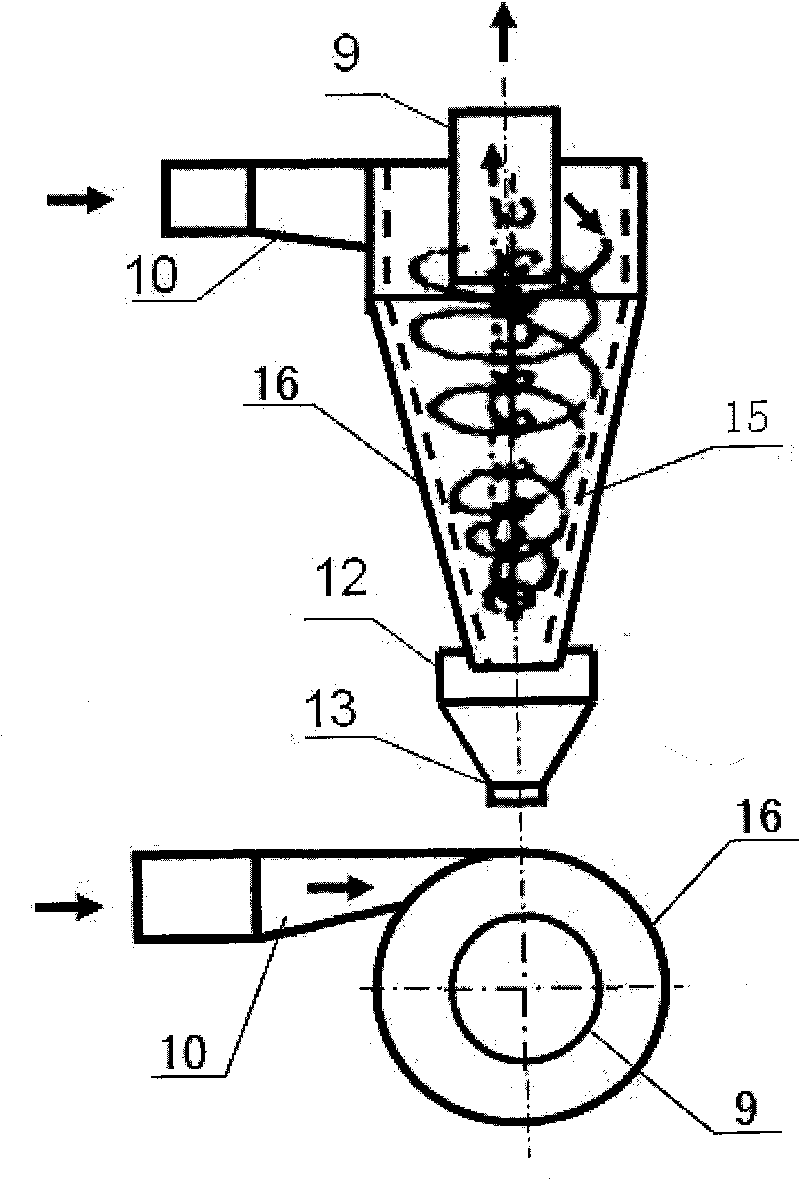

Method used

Image

Examples

Embodiment 1

[0042] The silicon tetrachloride waste is distilled and purified to 7N grade, and the metal zinc obtained by electrolysis is distilled and purified to 7N grade. The temperature of the reducing agent storage chamber and the reaction chamber is controlled at 780°C. The heated and melted liquid zinc is added to the reducing agent storage tank of the reducing agent storage room through the reducing agent liquid inlet, and the liquid zinc enters the reaction nozzle under the action of gravity, and the 7N grade silicon tetrachloride gas is formed by SiCl 4 The inlet pipe is sprayed into the reaction nozzle, and liquid zinc and 7N grade silicon tetrachloride gas undergo a gas-liquid reduction reaction at a temperature of 780 ° C, as follows:

[0043] SiCl 4 (g)+2Zn(l)→Si(s)+2ZnCl 2 (g)

[0044] To prevent the reducing agent from encountering SiCl 4 Cold air absorbs heat and solidifies, SiCl 4 in SiCl 4 The preparation system was heated to a reaction temperature of 780°C.

[00...

Embodiment 2

[0052] Metallurgical grade silicon tetrachloride is distilled and purified to 7N grade, and metal zinc obtained by electrolysis is distilled and purified to 7N grade. The temperature of the reducing agent storage chamber and the reaction chamber is controlled at 900°C. The heated and melted liquid zinc is added to the reducing agent storage tank of the reducing agent storage room through the reducing agent liquid inlet, and the liquid zinc enters the reaction nozzle under the action of gravity, and the 7N grade silicon tetrachloride gas is formed by SiCl 4 The inlet pipe is sprayed into the reaction nozzle, and liquid zinc and 7N grade silicon tetrachloride gas undergo a gas-liquid reduction reaction at a temperature of 900 ° C, as follows:

[0053] SiCl 4 (g)+2Zn(l)→Si(s)+2ZnCl 2 (g)

[0054] To prevent the reducing agent from encountering SiCl 4 Cold air absorbs heat and solidifies, SiCl 4 in SiCl 4 The preparation system was heated to a reaction temperature of 900°C. ...

Embodiment 3

[0062] The silicon tetrachloride waste is distilled and purified to 7N grade, and the metal zinc obtained by electrolysis is distilled and purified to 7N grade. The temperature of the reducing agent storage chamber and the reaction chamber is controlled at 650°C. The heated and melted liquid zinc is added to the reducing agent storage tank of the reducing agent storage room through the reducing agent liquid inlet, and the liquid zinc enters the reaction nozzle under the action of gravity, and the 7N grade silicon tetrachloride gas is formed by SiCl 4 The inlet pipe is sprayed into the reaction nozzle, and liquid zinc and 7N grade silicon tetrachloride gas undergo a gas-liquid reduction reaction at a temperature of 650°C, as follows:

[0063] SiCl 4 (g)+2Zn(l)→Si(s)+2ZnCl 2 (g)

[0064] To prevent the reducing agent from encountering SiCl 4 Cold air absorbs heat and solidifies, SiCl 4 in SiCl 4 The preparation system was heated to a reaction temperature of 650°C.

[0065...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com