Method for preparing high temperature superconduction coating conductor buffer layer using polymer auxiliary azotate deposition

A polymer-assisted, high-temperature superconducting technology, applied in the use of superconducting elements, superconducting/high-conducting conductors, manufacturing/processing of superconducting devices, etc. and other problems, to achieve the effect of smooth and dense surface, easy operation and control, and good performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0026] A kind of specific embodiment of the present invention is:

[0027] A kind of polymer-assisted nitrate deposition prepares the method for high-temperature superconducting coating conductor buffer layer, and its specific method is:

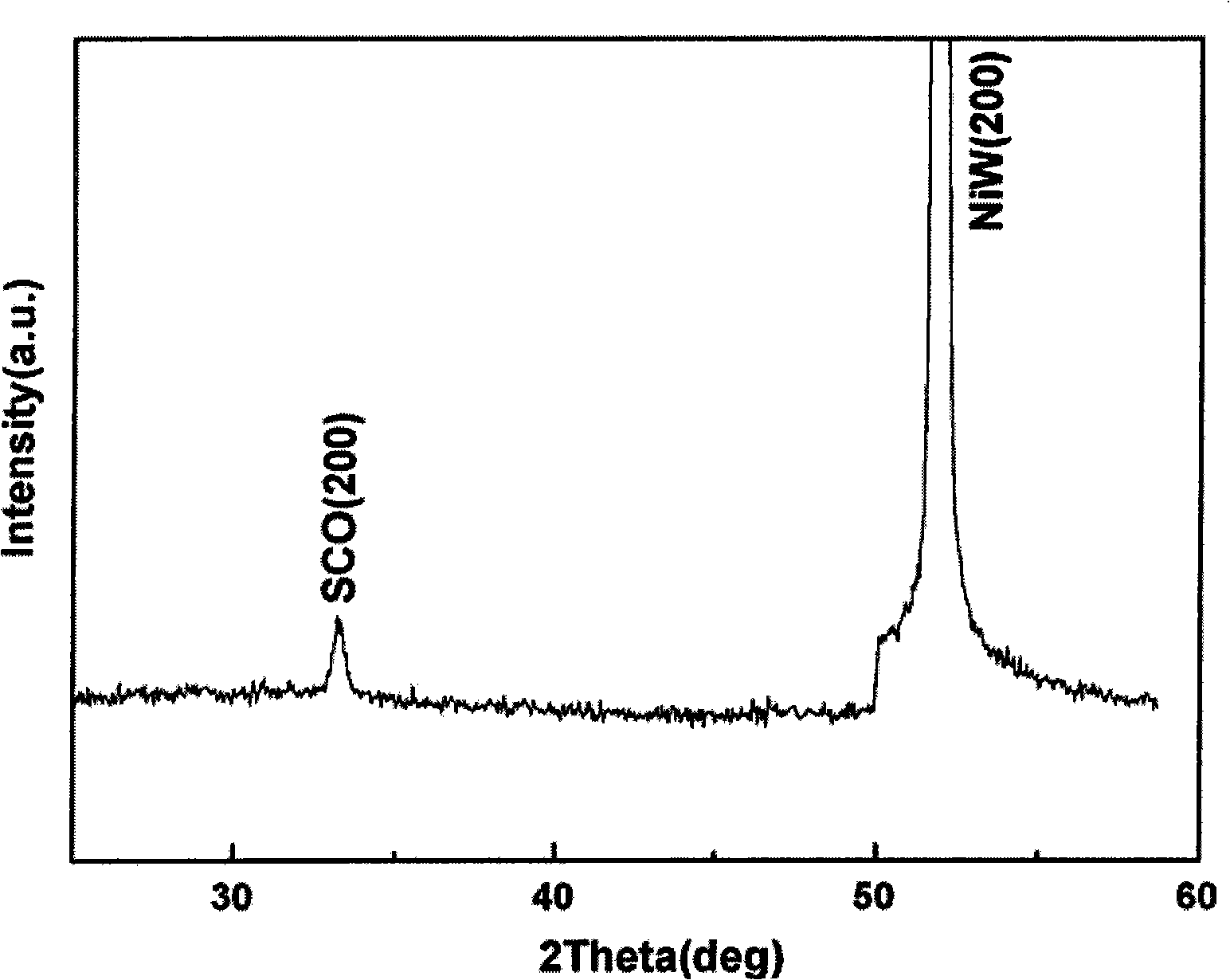

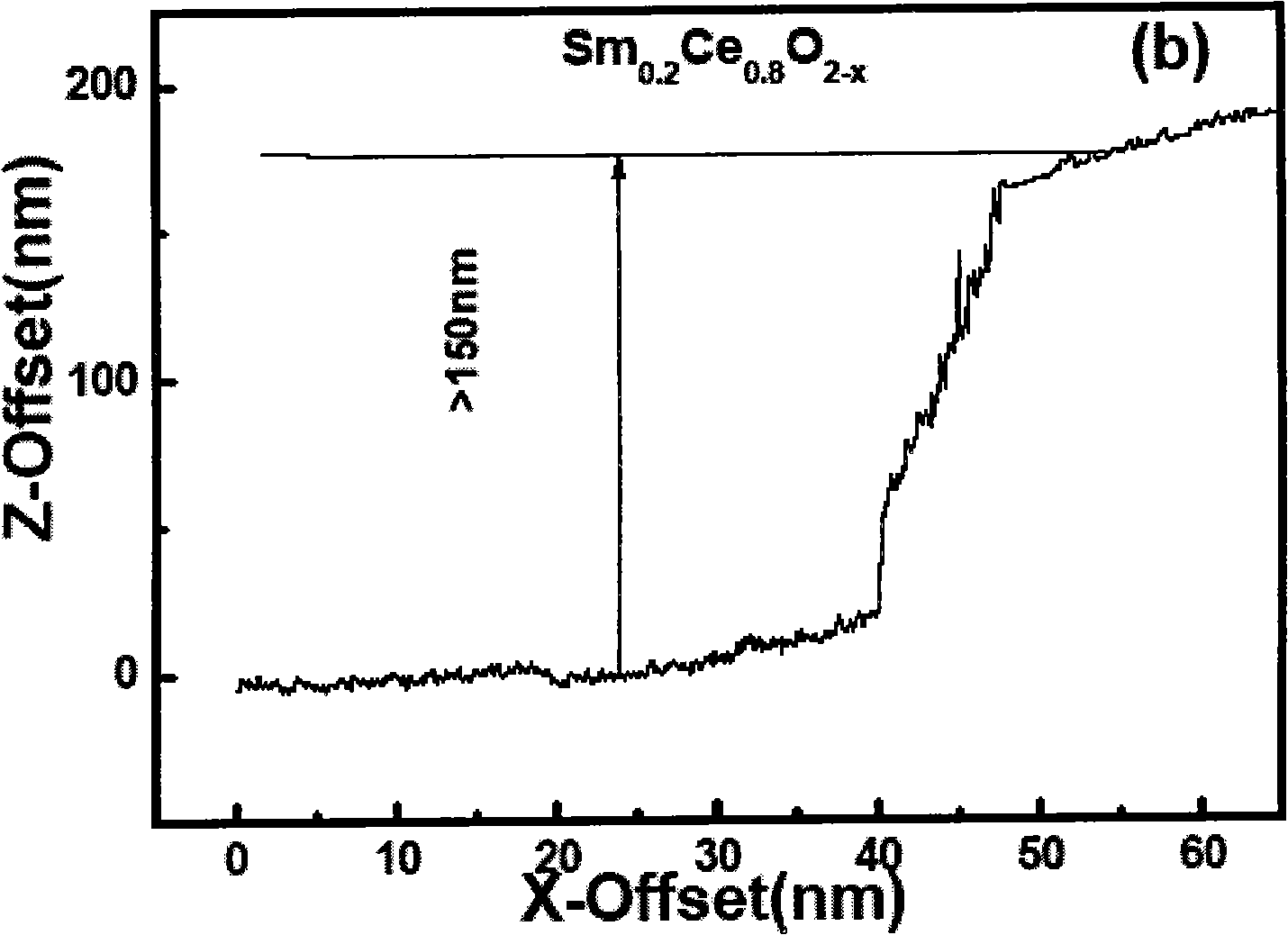

[0028] a, preparation of anhydrous solution: the rare earth nitrate samarium nitrate and cerous nitrate are dissolved in the organic solvent N, N-dimethylformamide (DMF) according to the ratio of cations, namely Sm: Ce=0.2: 0.8, to form anhydrous aqueous solution.

[0029] b. Preparation of colloid: Add polymer material polyacrylic acid (PAA) to the anhydrous solution in step a to form a colloid with good film-forming properties.

[0030] c. Colloid coating and drying: the colloid prepared in step b is coated on the Ni alloy substrate, and then dried at a temperature of 150°C.

[0031] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace ...

Embodiment 2

[0034] The specific approach in this example is:

[0035] a, preparation of anhydrous solution: holmium nitrate and cerous nitrate are dissolved in N, N-dimethylformamide (DMF) according to the ratio of cations, i.e. Ho: Ce=0.01: 0.99, to form an anhydrous solution;

[0036] B, colloid preparation: add polymethacrylic acid (PMAA) in the anhydrous solution of step a, form the good colloid of film-forming property;

[0037] c. Colloid coating and drying: Coat the colloid prepared in step b on the Ni alloy substrate, and then place it at 100°C for drying;

[0038] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace from room temperature to 200°C, and increase it to 280°C at a speed of 0.1°C / min, and keep it warm for 15 minutes .

[0039] d. Sintering phase formation: put the thermally decomposed substrate into the sintering furnace, rapidly raise the furnace temperature to 85...

Embodiment 3

[0041] The specific approach in this example is:

[0042] a, preparation of anhydrous solution: zirconium nitrate and cerous nitrate are dissolved in N,N-dimethylformamide (DMF) according to the ratio of cations, namely Zr: Ce=0.5:0.5, to form an anhydrous solution;

[0043] B, colloid preparation: add polyacrylic acid (PAA) in the anhydrous solution of a step, form the good colloid of film-forming property;

[0044] c. Colloid coating and drying: Coat the colloid prepared in step b on the Ni alloy substrate, and then dry at 200°C;

[0045] Thermal decomposition treatment before sintering: place the colloid-coated substrate in a sintering furnace, slowly increase the temperature of the furnace from room temperature to 230°C, and increase to 400°C at a rate of 1°C / min, and keep it for 20 minutes.

[0046] d. Sintering phase formation: put the thermally decomposed substrate into the sintering furnace, rapidly raise the furnace temperature to 1150°C at 100°C / min, keep it warm fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com