Cold-stirring and cold-paving all-in-one machine

An all-in-one, cold-paving technology, applied in the direction of roads, road repair, roads, etc., can solve the problems that the arrival temperature of asphalt mixture cannot be guaranteed, the construction process of cold-mix cold-paving cannot be satisfied, and the heating of raw materials consumes large energy, etc., and saves energy. Labor cost, improving construction quality and efficiency, and saving labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

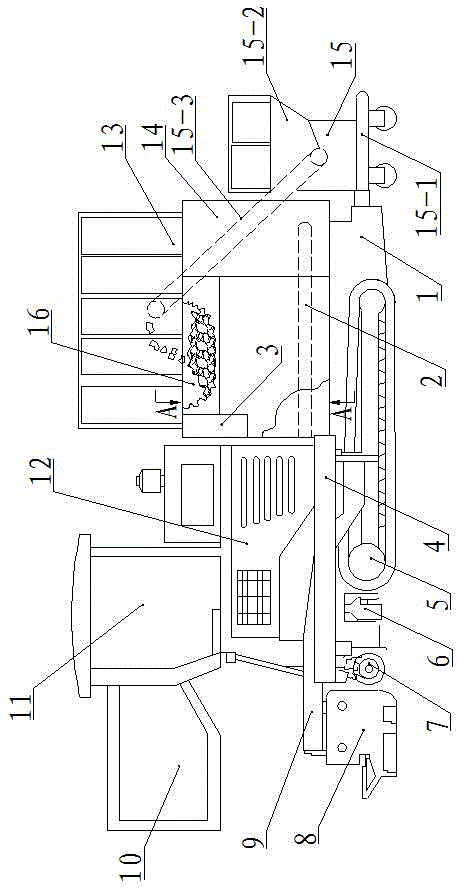

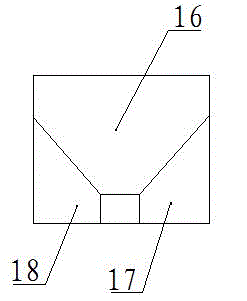

[0033] Such as figure 1 and figure 2 As shown, a cold-mixing and cold-paving integrated machine includes a frame 1, a power assembly 12 arranged on the upper rear of the frame 1, and a running mechanism 5 arranged on the lower side of the frame 1 and connected to the power assembly 12, The front part of the upper side of the frame 1 is provided with an aggregate bin 16, an emulsified asphalt storage device 17 and a water storage device 18, the rear side of the aggregate bin 16 is provided with a cement storage device 3, and the front side of the aggregate bin 16 is A transmission auxiliary device 14 connected with the power assembly 12 is provided. A driver's cab 11 is arranged on the upper side of the power assembly 12, and an asphalt spreading tank 10 is arranged on the rear side of the driver's cab 11. Between the power assembly 12 and the frame 1 There is a stirring device 4 in communication with the aggregate bin 16, the emulsified asphalt storage device 17 and the wate...

Embodiment 2

[0037] Such as figure 1 and figure 2 As shown, a cold-mixing and cold-paving integrated machine includes a frame 1, a power assembly 12 arranged on the upper rear of the frame 1, and a running mechanism 5 arranged on the lower side of the frame 1 and connected to the power assembly 12, The front part of the upper side of the frame 1 is provided with an aggregate bin 16, an emulsified asphalt storage device 17 and a water storage device 18, the rear side of the aggregate bin 16 is provided with a cement storage device 3, and the front side of the aggregate bin 16 is A transmission auxiliary device 14 connected with the power assembly 12 is provided. A driver's cab 11 is arranged on the upper side of the power assembly 12, and an asphalt spreading tank 10 is arranged on the rear side of the driver's cab 11. Between the power assembly 12 and the frame 1 There is a stirring device 4 in communication with the aggregate bin 16, the emulsified asphalt storage device 17 and the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com