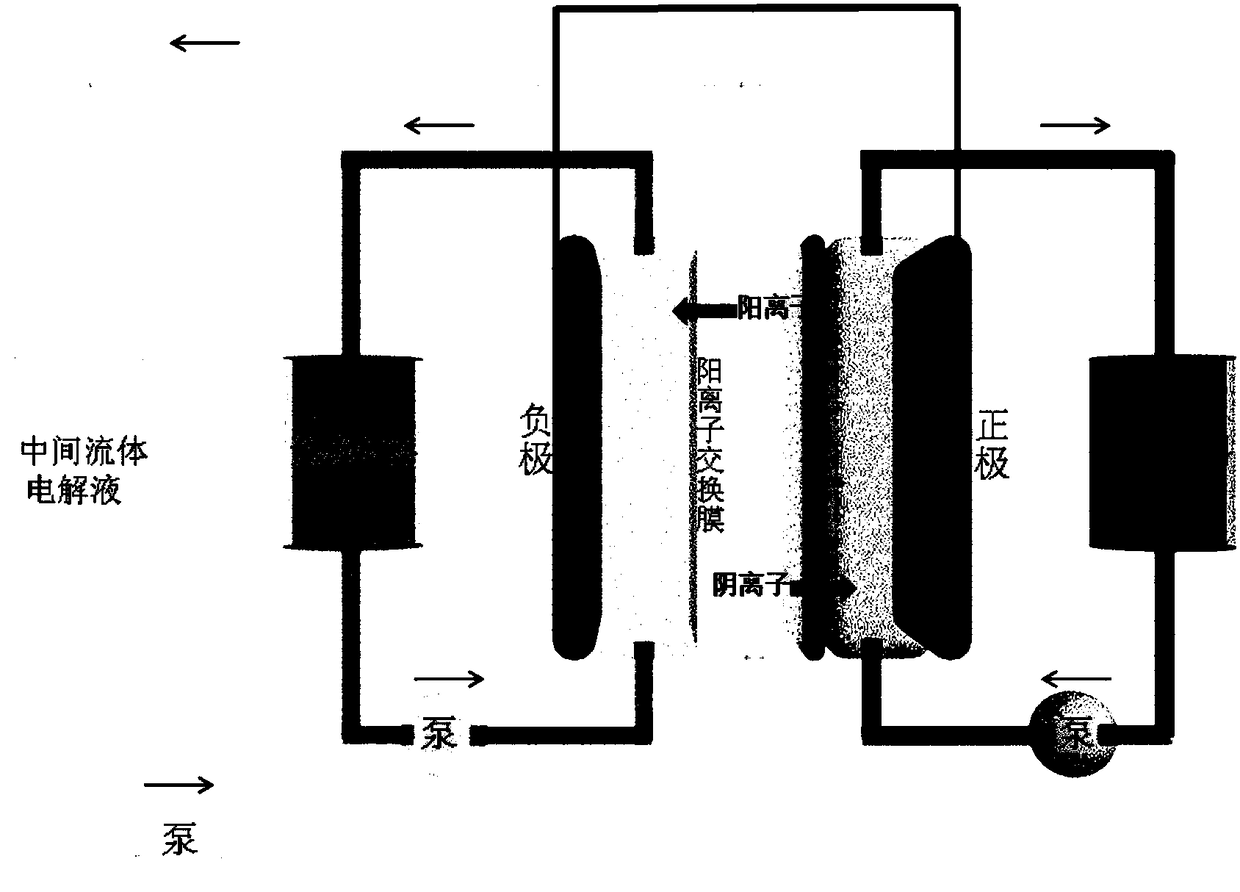

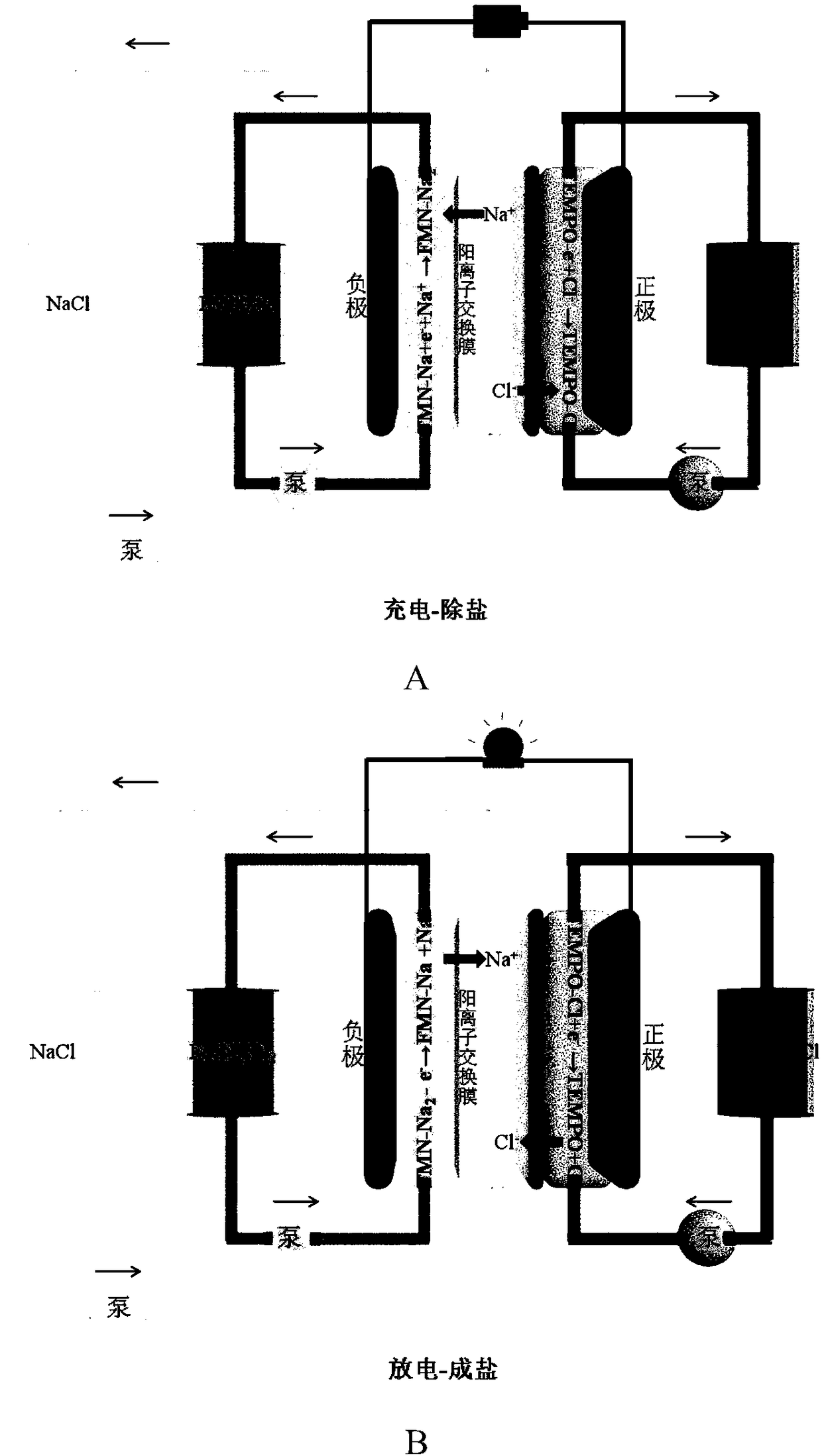

Method for removing salt by using fluid battery and application thereof

A fluid battery, electrolyte technology, applied in the field of desalination, can solve problems such as poor desalination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

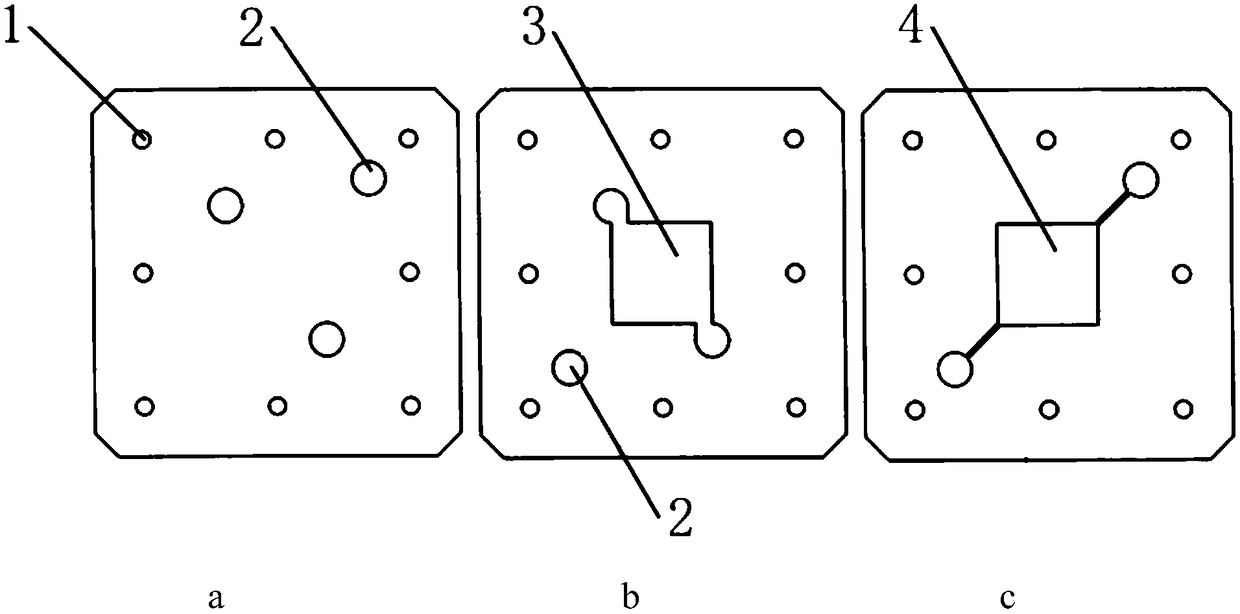

[0075] (1) First cut the carbon paper, the homogeneous anion exchange membrane with quaternary amine groups and the homogeneous cation exchange membrane with sulfonic acid groups into a square of 11*11 cm, which is the same as the mold size of the flow battery device (11*11 *1cm), and then punch holes in the carbon paper and the anion and cation exchange membranes to fix the device with screws, which is beneficial to maintain the pressure during the reaction and prevent the materials from contaminating each other. Then put the cut carbon paper into a 1000ml beaker, pour 150ml of 4% (w / w) hydrochloric acid into it and ultrasonicate for 5min, the ultrasonic power is 200W. Then the hydrochloric acid was poured out, rinsed with deionized water, and then poured into 150ml of absolute ethanol and sonicated for 5min (power 200W). Finally, deionized ethanol was poured out, rinsed with deionized water, and then ultrasonicated with deionized water for 5 minutes (power 200W). After the ...

Embodiment 2

[0083] (1) First cut the carbon paper, the homogeneous anion exchange membrane with quaternary amine groups and the homogeneous cation exchange membrane with sulfonic acid groups into a square of 11*11 cm, which is the same as the mold size of the flow battery device (11*11 *1cm), and then punch holes in the carbon paper and the anion and cation exchange membranes to fix the device with screws, which is beneficial to maintain the pressure during the reaction and prevent the materials from contaminating each other. Then put the cut carbon paper into a 1000ml beaker, pour 150ml of 4.5% (w / w) hydrochloric acid into it and sonicate it for 10min, and the ultrasonic power is 150W. Subsequently, the hydrochloric acid was poured out, rinsed with deionized water, and then poured into 150ml of absolute ethanol and sonicated for 10min (power 150W). Finally, the absolute ethanol was poured out, rinsed with deionized water, and then ultrasonicated with deionized water for 10 minutes (power...

Embodiment 3

[0090] (1) First cut the carbon paper, the homogeneous anion exchange membrane with quaternary amine groups and the homogeneous cation exchange membrane with sulfonic acid groups into a square of 11*11 cm, which is the same as the mold size of the flow battery device (11*11 *1cm), and then punch holes in the carbon paper and the anion and cation exchange membranes to fix the device with screws, which is beneficial to maintain the pressure during the reaction and prevent the materials from contaminating each other. Then put the cut carbon paper into a 1000ml beaker, first pour 150ml of 5% (w / w) hydrochloric acid into the ultrasonic for 15min, and the ultrasonic power is 100W. Subsequently, the hydrochloric acid was poured out, rinsed with deionized water, and then poured into 150 ml of absolute ethanol and sonicated for 15 min (power 100 W). Finally, the absolute ethanol was poured out, rinsed with deionized water, and then ultrasonicated with deionized water for 15 minutes (po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com