Nano silicon composite negative electrode material for lithium ion battery, preparation method and lithium ion battery

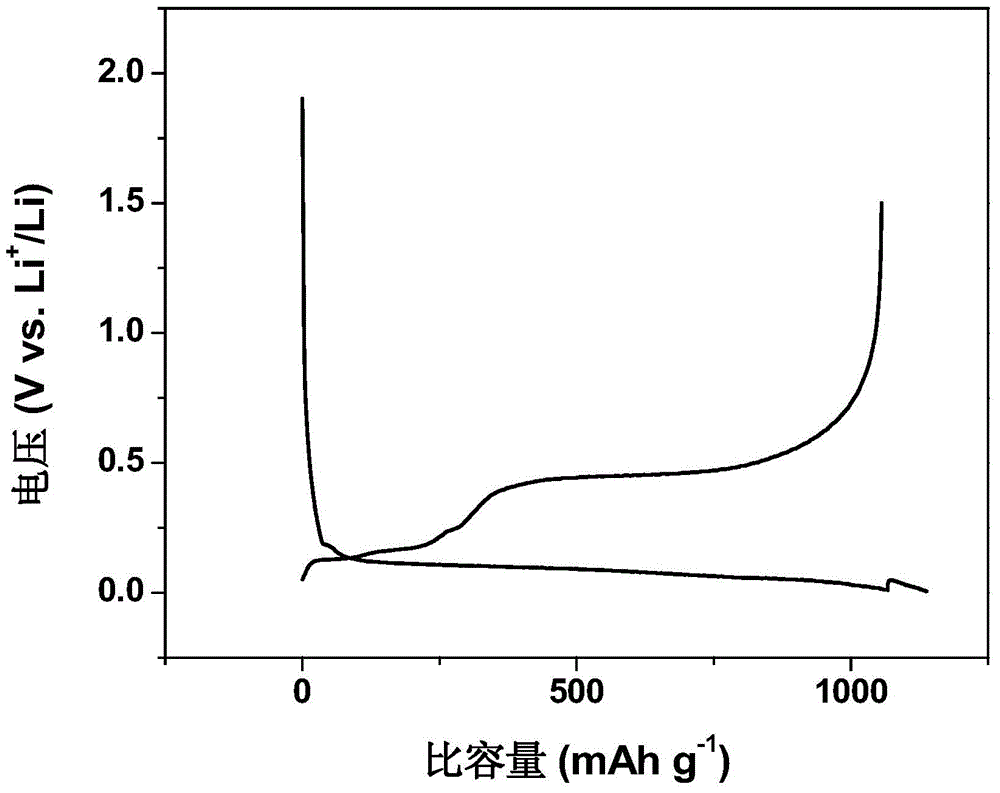

A negative electrode material and nano-silicon technology, applied in the field of lithium-ion batteries, can solve the problems of small pores, difficult to effectively carry nano-silicon materials, difficult to achieve uniform deposition of nano-silicon materials, etc. The effect of high first charge-discharge efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

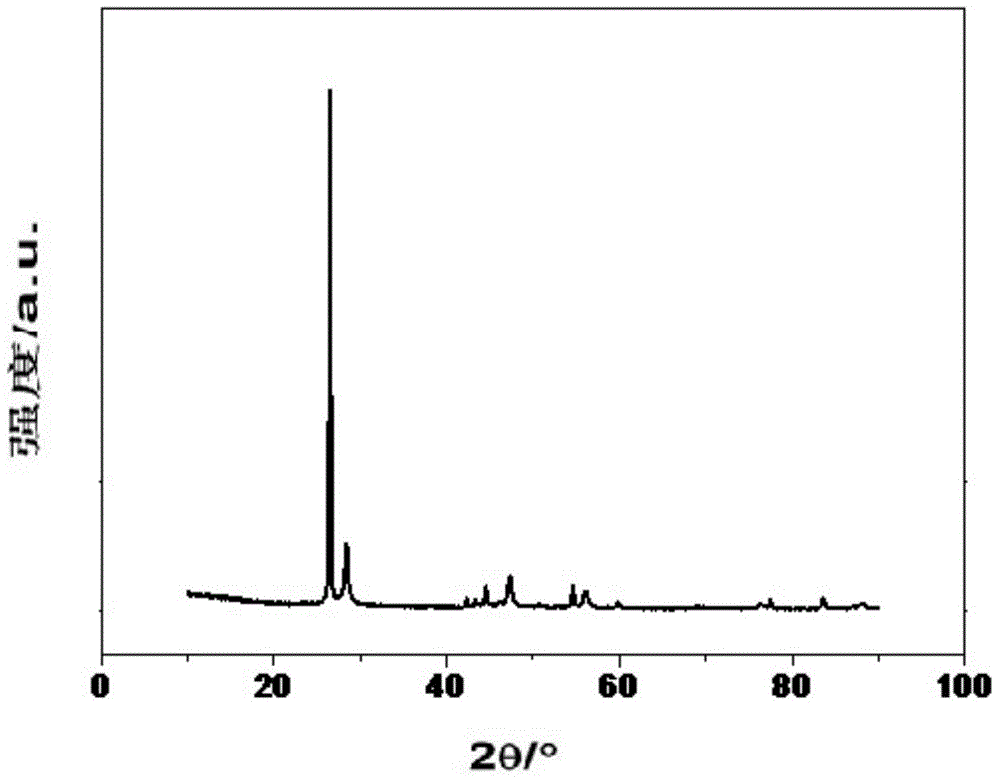

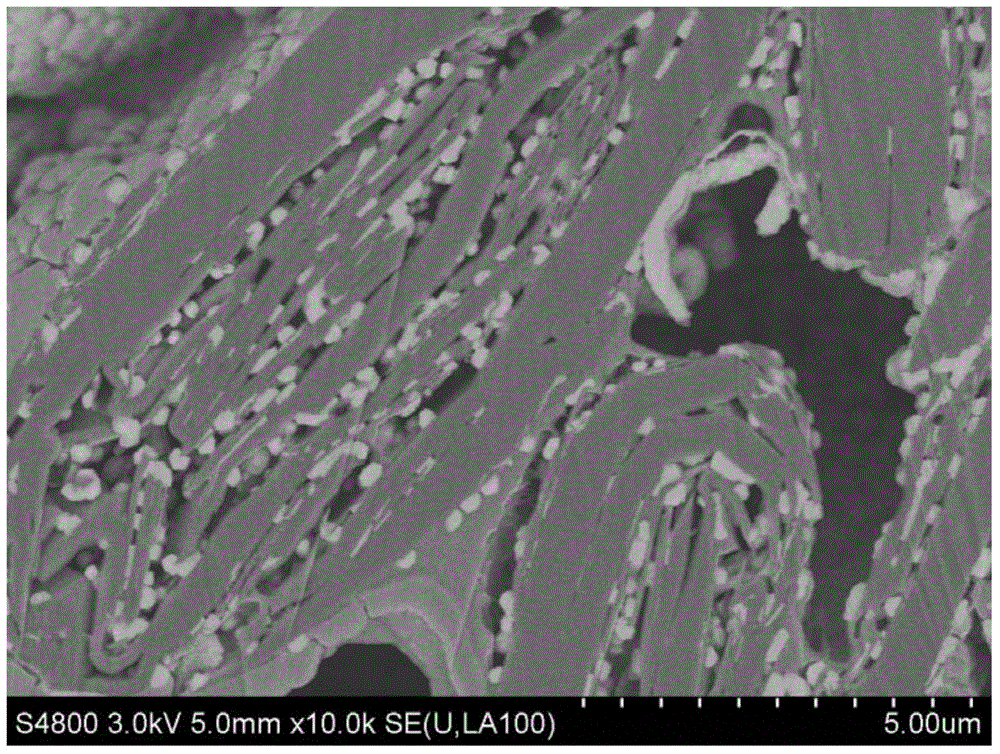

[0053] (1) Add 500g of natural spherical graphite powder with an average particle size of 16-19μm and a carbon content of 99.95% and 1L of water into the ball milling tank, stir evenly, add 4kg of zirconia balls with a diameter of 10mm, the ball milling speed is 480r / min, and the ball milling time is 5 -25h, suction filtration and drying to obtain a hollow graphite material with a particle size of 1.0 μm;

[0054] (2) Put 500g of hollow graphite in a rotary furnace, adjust the rotation speed to 0.5r / min, and heat up to 700°C at a heating rate of 5.0°C / min under the protection of a high-purity nitrogen flow rate of 1.0L / min. Switch the high-purity nitrogen to a mixture of high-purity hydrogen and SiHCl3, keep the flow rate at 10.0L / min, switch the gas to high-purity nitrogen after a constant temperature of 3.0h, and cool to room temperature naturally to obtain hollow graphite / nano-silicon composite materials, nano The average particle size of the silicon material is 80.0nm;

...

Embodiment 2

[0061] (1) Add 500g of artificial graphite powder with an average particle size of 10-13 μm and 99.95% carbon content and 1L of water into the ball milling tank, stir evenly, add 3kg of zirconia balls with a diameter of 5mm, the ball milling speed is 800r / min, and the ball milling time is 25- 40h, suction filtration and drying to obtain a hollow graphite material with a particle size of 8.0 μm;

[0062] (2) Put 500g of hollow graphite in a rotary furnace, adjust the rotation speed to 2.0r / min, and heat up to 500°C at a heating rate of 3.0°C / min under the protection of a high-purity nitrogen flow rate of 1.0L / min. Switching from high-purity nitrogen to high-purity hydrogen and SiH 4 The mixed gas, the flow rate is maintained at 2.0L / min, and the gas is converted into high-purity nitrogen gas after a constant temperature of 0.5h, and naturally cooled to room temperature to obtain a hollow graphite / nano-silicon composite material, and the average particle size of the nano-silicon...

Embodiment 3

[0066] (1) Add 500g of natural spherical graphite powder with an average particle size of 16-19μm and a carbon content of 99.95% and 1L of water into the ball milling tank, stir evenly, add 4kg of zirconia balls with a diameter of 3mm, the ball milling speed is 800r / min, and the ball milling time is 40 -60h, suction filtration and drying to obtain a hollow graphite material with a particle size of 5.0 μm;

[0067] (2) Put 500g of hollow graphite in a tube furnace, at a heating rate of 5.0°C / min, under the protection of a high-purity nitrogen flow rate of 2.5L / min, after heating up to 1000.0°C, switch from high-purity nitrogen to high-purity Hydrogen and SiCl 4 The mixed gas, the flow rate is maintained at 10.0L / min, and the gas is converted into high-purity nitrogen after 8.0 hours of constant temperature, and naturally cooled to room temperature to obtain a hollow graphite / nano-silicon composite material. The average particle size of the nano-silicon material is 1000.0nm;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com