Positive electrode material of lithium cell, preparation method of positive electrode material and lithium cell

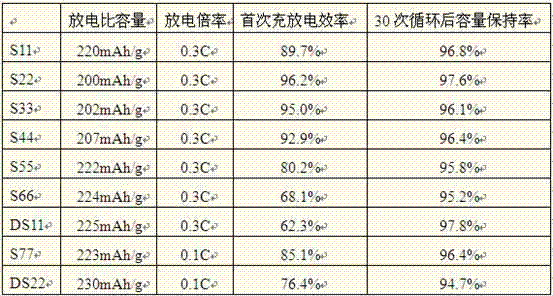

A lithium-ion battery, cathode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low initial charge and discharge efficiency, low cycle performance, etc., and achieve high initial charge and discharge efficiency, high cycle performance, and technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The present invention also provides a preparation method for the positive electrode material of the lithium ion battery, comprising the following steps:

[0020] 1) Formulated with Mn 4+ , M 3+ The aqueous solution is added to the water-soluble carbonate solution under stirring, and after the precipitation is complete, it is dried to obtain the layered composite solid solution precursor;

[0021] 2) Preparation of SnCl 4 In the organic solution, add ammonia water in the stirring state until the precipitation is complete, separate the organic phase after extraction, distill and dry to obtain SnO 2 Precursor;

[0022] 3) The layered composite solid solution precursor, SnO 2 The precursor and the lithium salt are uniformly mixed according to the stoichiometric ratio, and after pre-sintering, the sintering is continued in an oxygen atmosphere to obtain the lithium ion cathode material.

[0023] According to the preparation method of the present invention, first prepare...

Embodiment 1

[0047] (1) Preparation of cathode material S1

[0048] Prepare Ni according to stoichiometric ratio 2 (SO 4 ) 3 , Mn(SO 4 ) 2 , Mn 2 (SO 4 ) 3 The mixed aqueous solution was slowly added dropwise into the sodium carbonate solution under high-speed stirring to obtain a precipitate; the precipitate was dried at 108°C to obtain a mixed x Li 2 MnO 3 y LiMO 2 precursor material.

[0049] To 20mL SnCl 4 Add 5g of sodium lauryl sulfate to the solution (concentration: 1mol / L), then add 10mL of n-heptane and 10mL of n-pentane, stir evenly, and drop in 1mol / L ammonia solution while stirring until the precipitation is complete; 100mLCHCl 3 Extract and separate, keep the organic phase, wash with distilled water, distill to nearly dry, and then dry the water at 50°C under infrared light to obtain SnO 2 precursor material.

[0050] Will x Li 2 MnO 3 y LiMO 2 Precursor material, SnO 2 Precursor material, Li 2 CO 3 Mix uniformly according to the stoichiometric ratio ba...

Embodiment 2

[0056] Adopt the method identical with embodiment 1 to prepare cathode material S2 and lithium ion battery S22, difference is:

[0057] In step (1), SnO 2 The amount of precursor material changes, so that in the positive electrode material S2, the layered composite solid solution is Li 1.2 Ni 0.215 mn 0.585 o 2 , content 95wt%; SnO 2 Content 5wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com