Lithium ion secondary cell

A secondary battery, lithium-ion technology, applied in secondary batteries, batteries, battery electrodes, etc., can solve the problems of poor battery technology, fast capacity decay, and short cruising range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The active material contained in the positive electrode described in the present invention includes LiNi 0.5 co 0.2 mn 0.3 o 2 (NCM523), where LiNi 0.5 co 0.2 mn 0.3 o2 After modification, it contains Mn, Na, K, Rb, Cs, Mg, Ca, Sr, Ba, Al, Ga, In, Ge, Sn, Ti, V, Cr, Fe, Cu, Zn, Y, Zr , Nb, Mo, Cd, W, La, Ce, Nd, Sb and Sm at least one element or its surface contains PO 4 3- ion. NCM523-Ti is the active material of the positive electrode material, and the surface of NCM523 is coated with oxide TiO 2 , the average particle size of the active material of the positive electrode material is measured by a laser particle size analyzer (D50) to be 6.8 μm, and the coating amount of the modified element compound on the active material of the positive electrode material is calculated as an oxide, accounting for about 10% of the total mass of the positive electrode material. 1.0 wt%. The preparation method is as follows: Dilute the stoichiometric titanium isopropoxide wit...

Embodiment 2

[0072] The positive active material is the same as in Example 1, and the battery manufacturing process is the same as in Example 1; the difference is that the negative active material is a mixture of soft carbon and artificial graphite, and the mass ratio of the two is 50:50. The composition of the electrolyte is shown in Table 5, the main solvents include EC, EMC, DMC, DEC, LiPF 6 The concentration is 0.10mol / L, the addition amount of VC is 0.5wt%, the addition amount of 1,3-PS is 2.5wt%, the addition amount of LiFSI is 5.0×10 -6 mol / mAh. Due to the difference in the ratio of components in the active material, the battery size is slightly different.

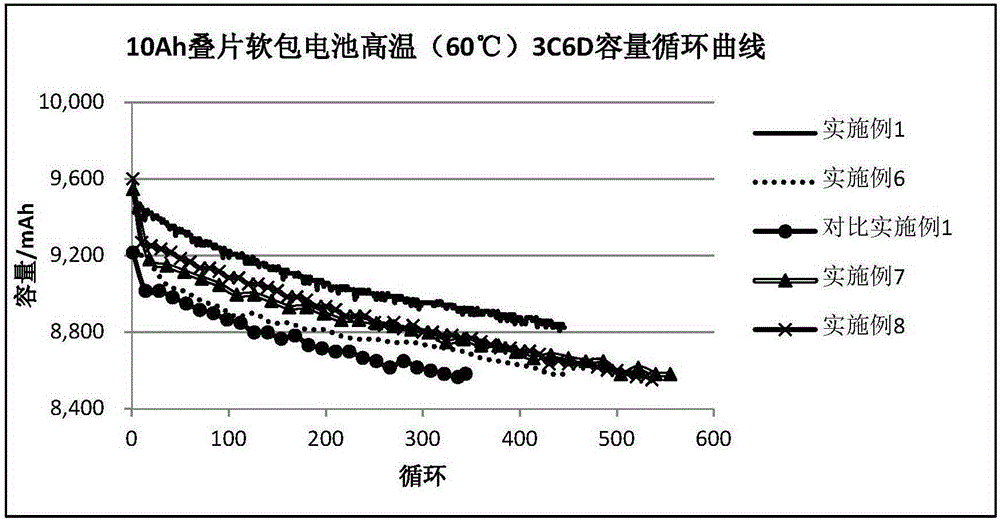

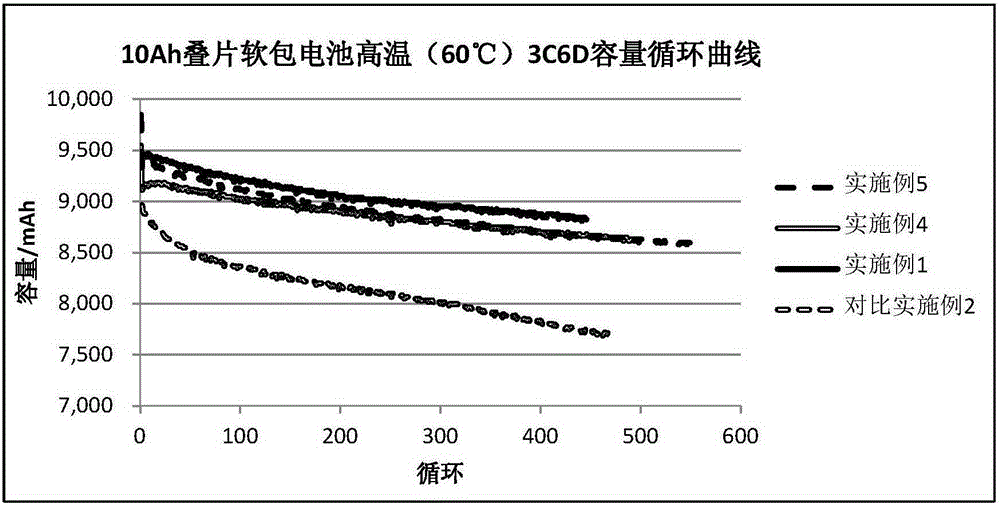

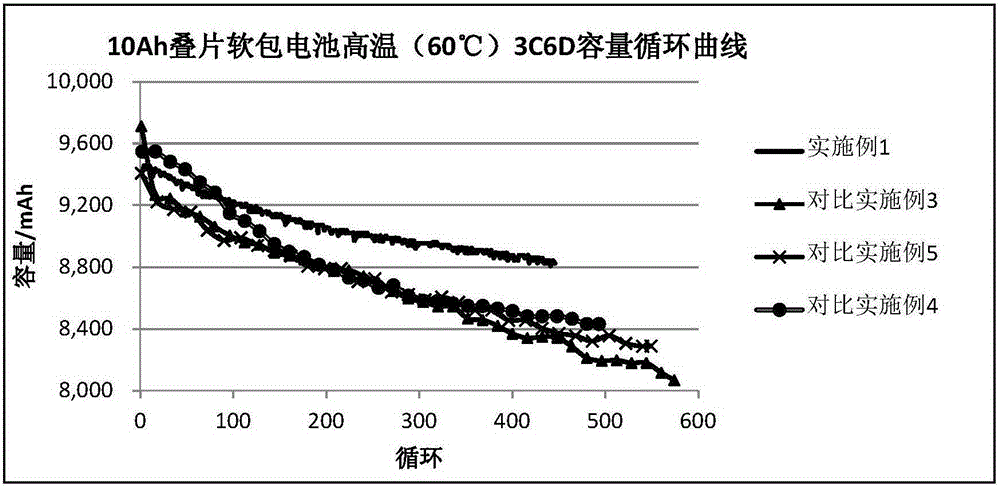

[0073] Battery life test: At an ambient temperature of 60°C, charge and discharge the above-mentioned soft-packaged battery within the voltage range of 2.75V to 4.10V, with a constant current charge rate of 3C and a constant current discharge rate of 6C, and investigate its high rate charge and discharge cycle under high temper...

Embodiment 3

[0075] NCM523-Zn is the active material of the positive electrode material. The surface of NCM523 is coated with oxide ZnO. The average particle size of the active material of the positive electrode material is 6.8 μm (D50) measured by a laser particle size analyzer. The modified element compound is used in the active material of the positive electrode material. The amount of coating on the oxide is calculated as 2.0wt% of the total mass of the positive electrode material. The preparation method is as follows: prepare stoichiometric nano-scale ZnO (D50<80nm), surfactant and water into a suspension solution, then add the active material of the positive electrode material, mix at a high speed for 15 minutes at room temperature, and then distill off the water. The mixture was heat-treated at 500° C. for 2 h in a high-temperature furnace to obtain NCM523-Zn cathode material. When designing the battery, the specific capacity of the NCM523-Zn positive electrode material is calculate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com