Quick formation method for lithium ion battery adapting to various cathode material systems

A technology of lithium ion battery and positive electrode material, applied in the field of formation of lithium ion battery, can solve the problems of shortening the formation time of small current, complicated formation method, long time consumption, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

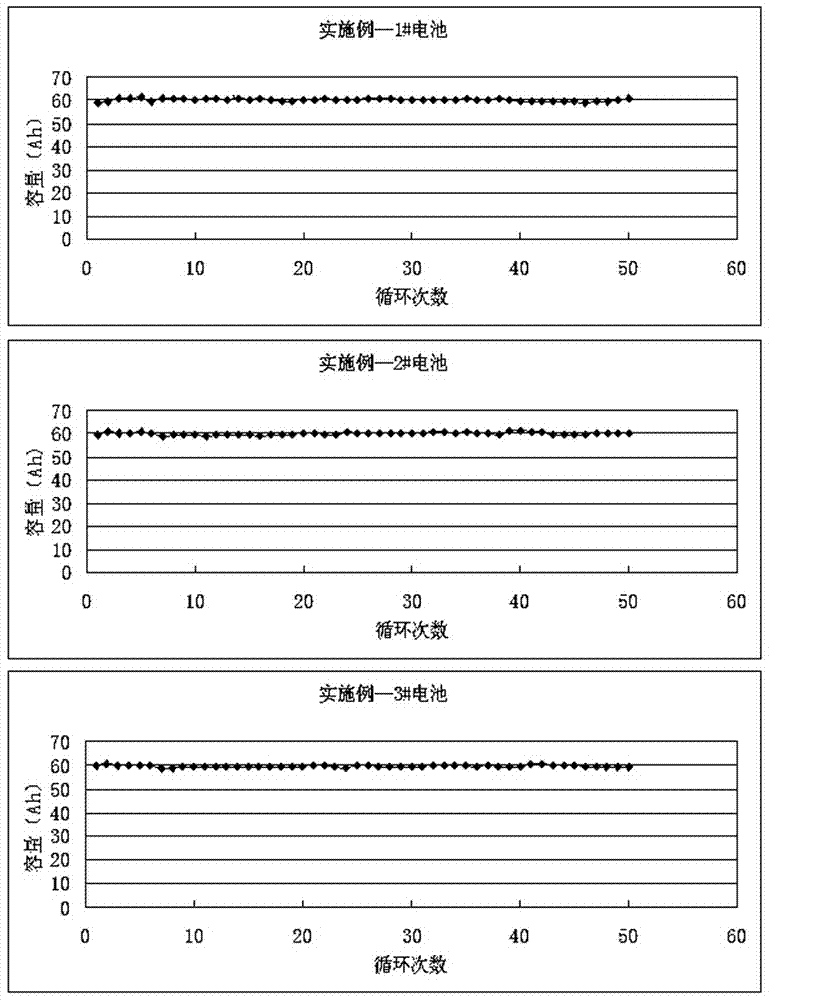

[0030] With lithium iron phosphate as the positive electrode and natural graphite as the negative electrode, 200 batteries were produced according to a process with a design capacity of 60Ah. They were divided into two groups, one group was the embodiment group, and the other group was the control group, each with 100 batteries.

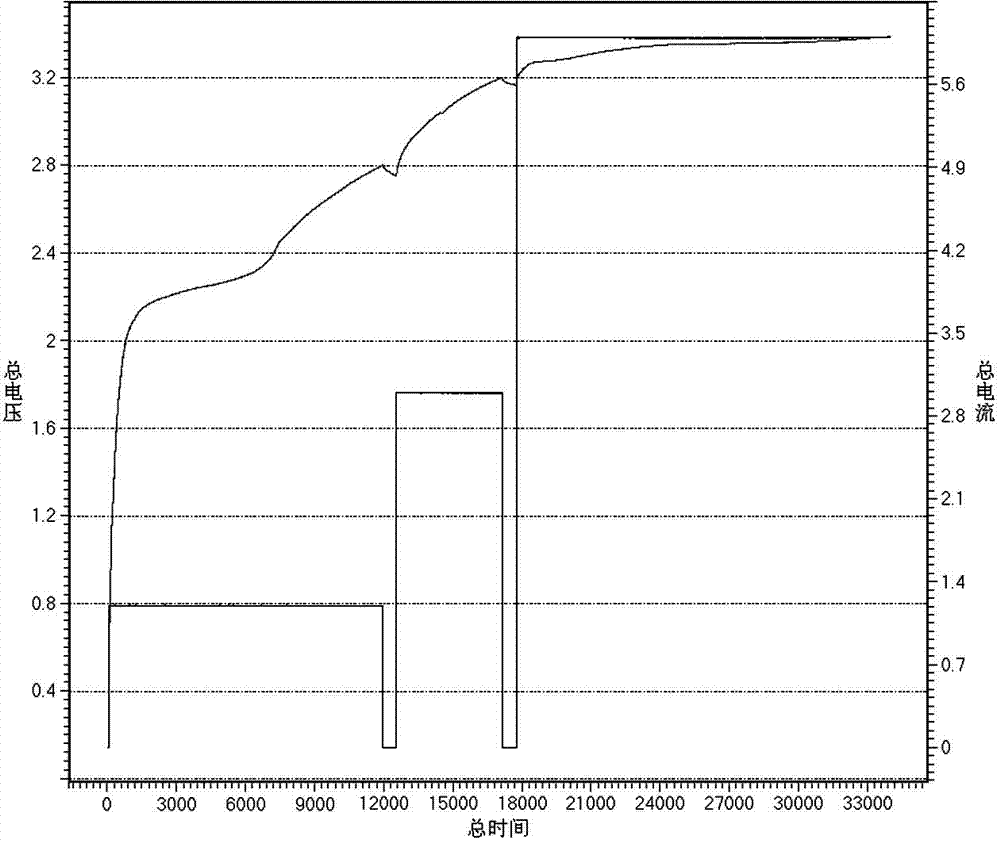

[0031] The 100 batteries of the embodiment group adopt the following formation method, such as figure 1 Shown:

[0032] The first stage: charge the battery with a constant current of 0.02C to the upper limit voltage of 2.8 volts, and stand for 45 minutes;

[0033] The second stage: charge the battery with a constant current of 0.05C to the upper limit voltage of 3.2 volts, and leave it for 45 minutes;

[0034] The third stage: The battery is charged with a constant current of 0.1C to the upper limit voltage of 3.4 volts, and the standing time is 36 hours;

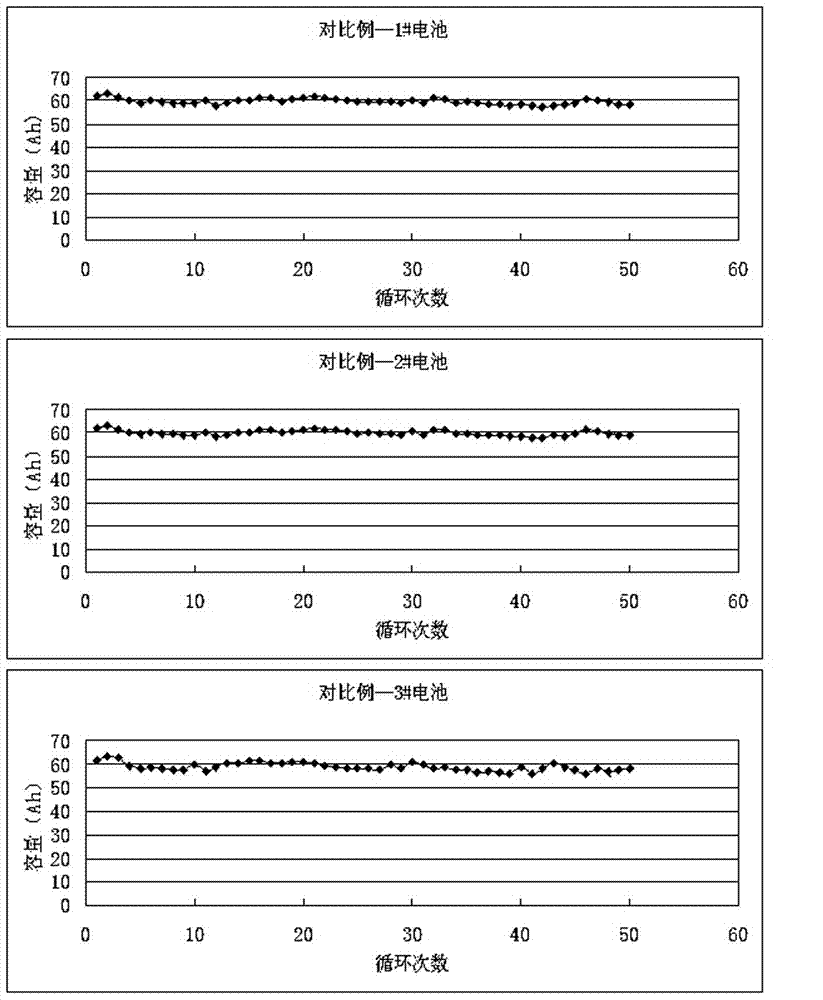

[0035] The 100 batteries in the control group use traditional formation methods, such as figure 2 Shown...

Embodiment 2

[0060] With lithium iron phosphate as the positive electrode and natural graphite as the negative electrode, it is produced according to a process with a design capacity of 60Ah, using the following chemical conversion method:

[0061] The first stage: The battery is charged with a constant current of 0.01C to the upper limit voltage of 2.7 volts, and the rest time is 20 minutes;

[0062] The second stage: charge the battery with a constant current of 0.07C to the upper limit voltage of 2.9 volts, and leave it for 5 minutes;

[0063] The third stage: Charge the battery with a constant current of 0.2C to the upper limit voltage of 3.2 volts, and let it stand for 10 minutes.

Embodiment 3

[0065] With lithium iron phosphate as the positive electrode and natural graphite as the negative electrode, it is produced according to a process with a design capacity of 60Ah, using the following chemical conversion method:

[0066] The first stage: charge the battery with a constant current of 0.04C to the upper limit voltage of 2.6 volts, and let it stand for 1 hour;

[0067] The second stage: charge the battery with a constant current of 0.04C to the upper limit voltage of 2.8 volts, and leave it for 3 hours;

[0068] The third stage: Charge the battery with a constant current of 0.09C to the upper limit voltage of 3.3 volts, and let it stand for 50 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com