Positive electrode material with improved first discharge capacity and preparation method thereof

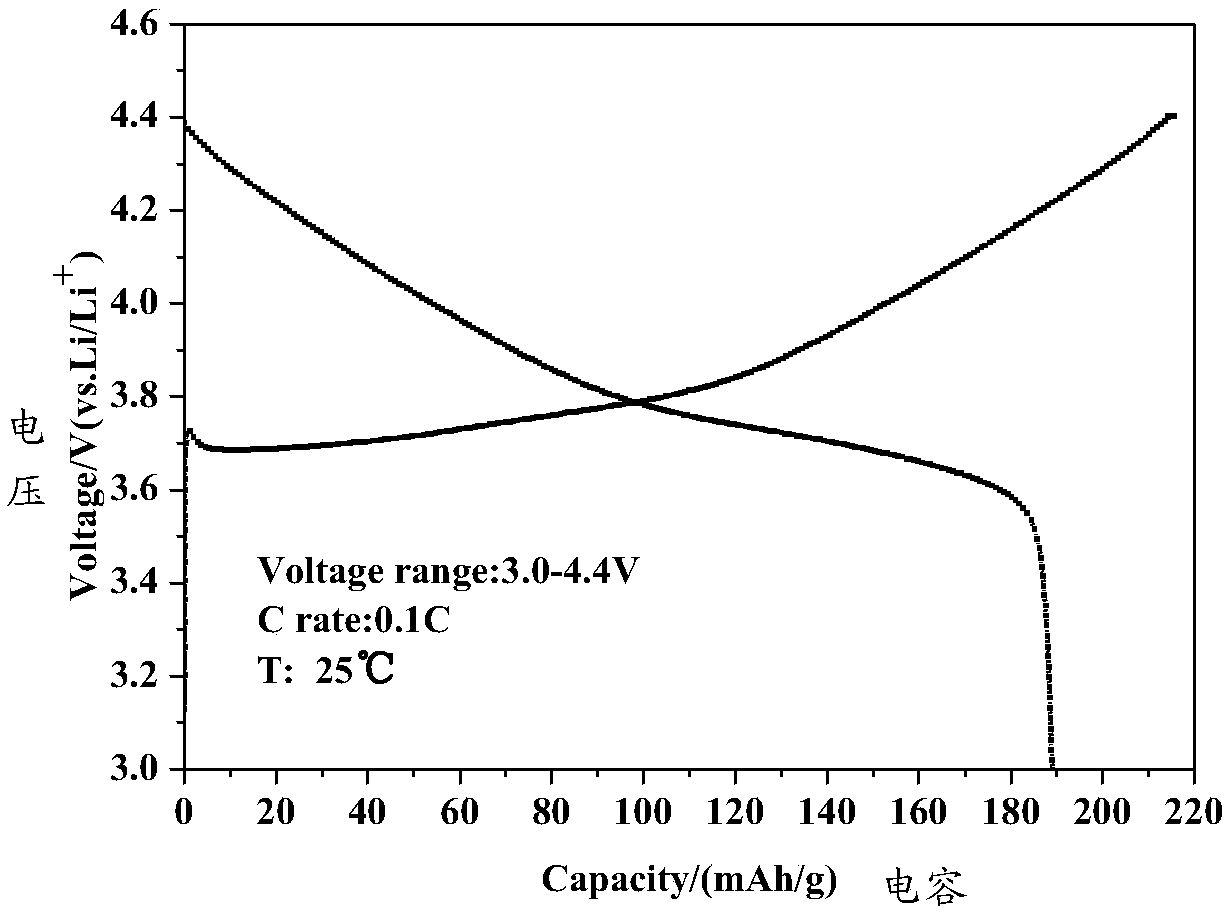

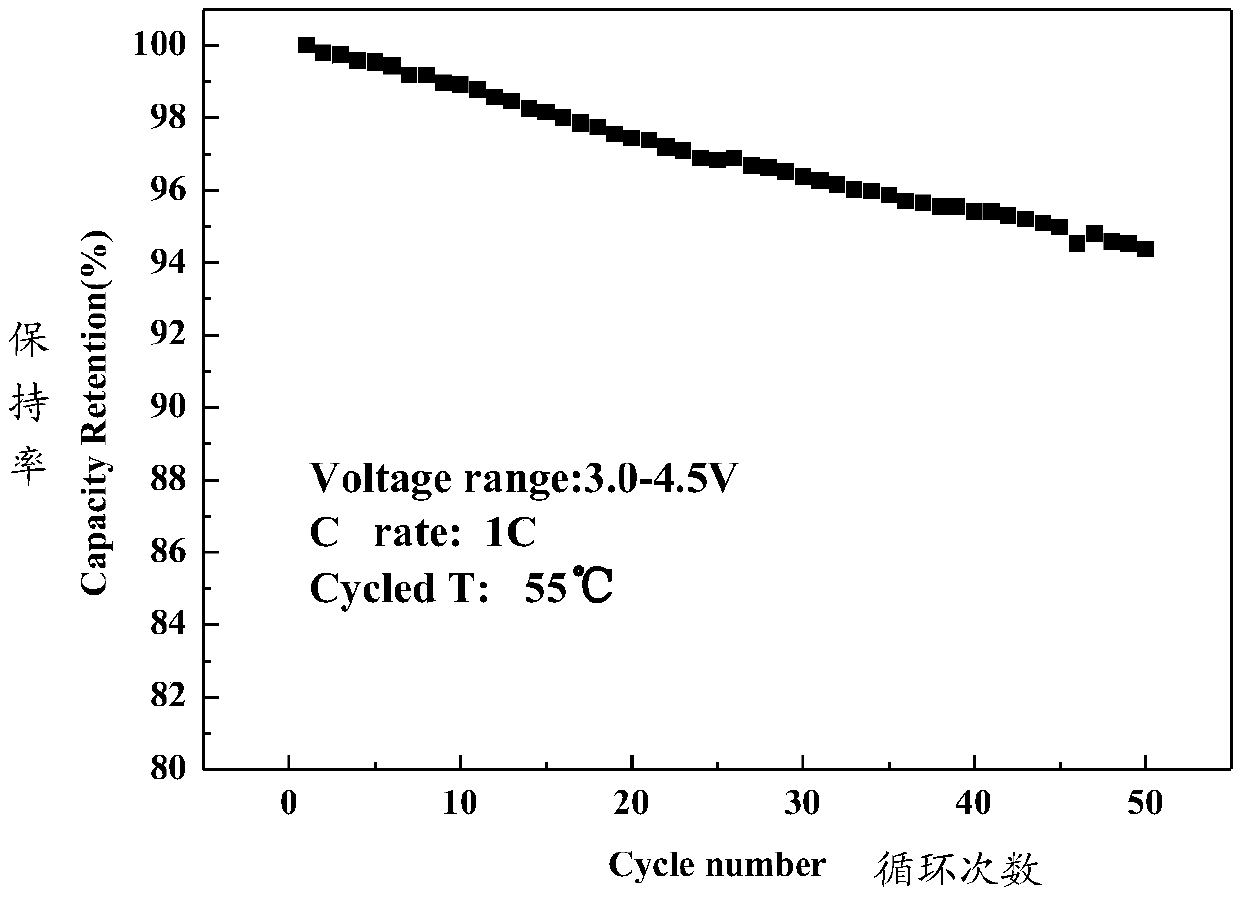

A cathode material and discharge capacity technology, applied in the field of materials research, can solve the problem of poor material cycle performance, achieve the effect of excellent performance, simple preparation process, and increase the discharge capacity in the first week

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the positive electrode material for improving the first discharge capacity comprises the following steps:

[0038] (1) After uniformly mixing the positive electrode material matrix and the lithium source, sintering to obtain a sintered material;

[0039] (2) Coating the sintered material obtained in step (1) with a coating agent.

[0040] Step (1) is lithium replenishment treatment, in step (1),

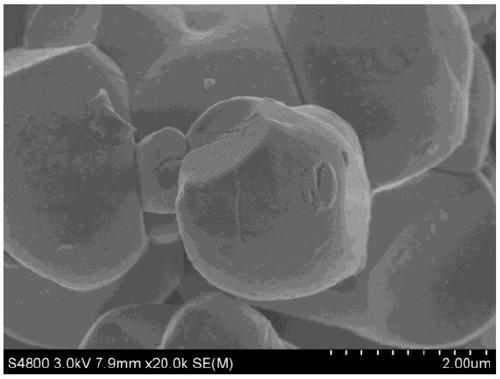

[0041] The positive electrode material matrix refers to a material that can be used as the positive electrode of a battery after sintering. The positive electrode material matrix includes any or a combination of NCM ternary material, NCA ternary material, lithium cobaltate, lithium iron phosphate, lithium manganate; preferably NCM ternary material-622 single crystal material (LiNi 0.6 co 0.2 mn 0.2 o 2 ).

[0042] The lithium source includes any or a combination of lithium hydroxide, lithium carbonate, lithium nitrate, lithium chloride, and lith...

Embodiment 1

[0087] (1) Take the positive electrode material LiNi 0.6 co 0.2 mn 0.2 o 2 Base M=200g, add LiOH 0.345g according to Li / M=0.05%, after mixing evenly, raise the obtained mixture sample from room temperature to 700°C in air atmosphere for secondary sintering, the heating rate is 5°C / min;

[0088] The sintering process is divided into two stages. Firstly, the temperature is raised to 500°C for 1 hour, then the temperature is raised to 700°C for 5 hours, and finally the temperature is naturally lowered. Pass the material obtained by secondary sintering through a 300-mesh sieve for later use.

[0089] (2) The material obtained in (1) is subjected to nano-H 3 BO 3 Dry coating. First, weigh 120g of the material in (1), and calculate the mass of the coating agent required based on the boron coating amount of 0.03% to be 0.206g. After mixing evenly, the mixture sample is sintered three times in an air atmosphere at 300°C, with a heating rate of 5 ℃ / min, holding time 5h, and fina...

Embodiment 2

[0091] (1) Take the positive electrode material LiNi 0.6 co 0.2 mn 0.2 o 2 Base M=200g, LiOH 0.345g was added according to Li / M=0.05%. After mixing evenly, the obtained mixture sample was raised from room temperature to 700°C in an air atmosphere for secondary sintering at a heating rate of 5°C / min. The sintering process is divided into two stages. Firstly, the temperature is raised to 500°C for 1 hour, then the temperature is raised to 700°C for 5 hours, and finally the temperature is naturally lowered. The material obtained by secondary sintering is passed through a 300-mesh sieve for subsequent use;

[0092] (2) The material obtained in (1) is subjected to nano-H 3 BO 3 Dry coating. First, weigh 120g of the material in (1), and calculate the mass of the coating agent required based on 0.05% of the boron coating amount to be 0.343g. After mixing evenly, the mixture sample is sintered three times in an air atmosphere at 300°C, with a heating rate of 5 ℃ / min, holding ti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com