Negative pole piece and lithium-ion battery

A negative pole piece, lithium ion technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limiting the fast charging ability of lithium ion batteries, limited lithium ion intercalation and extraction ability, etc., to improve the first charge and discharge efficiency, The effect of improving charging capacity and improving energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0055] Embodiment: Positive pole piece, negative pole piece and lithium ion battery and preparation method thereof:

[0056] (1) Preparation of positive electrode sheet 1 containing lithium supplementary layer:

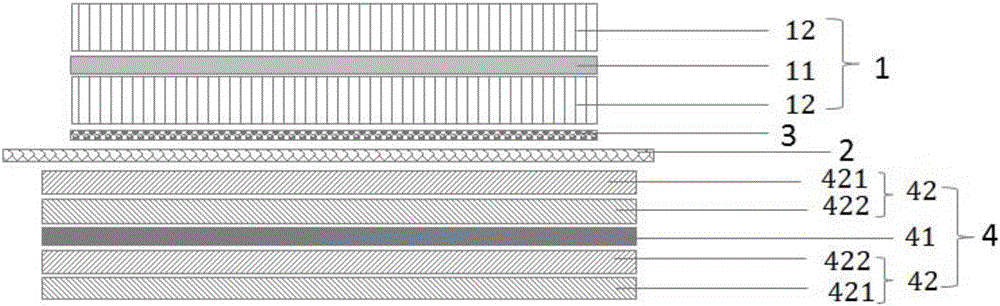

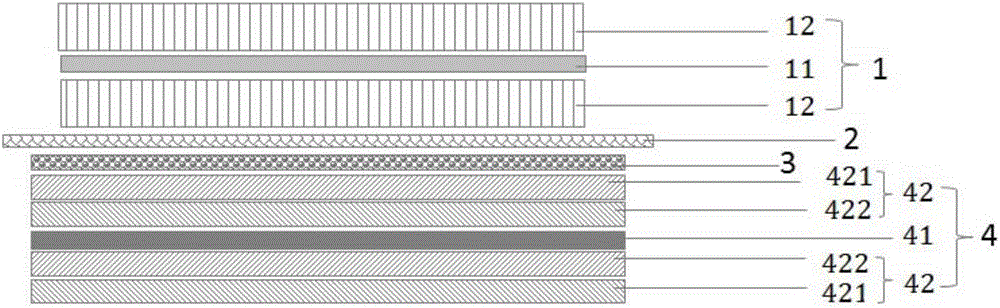

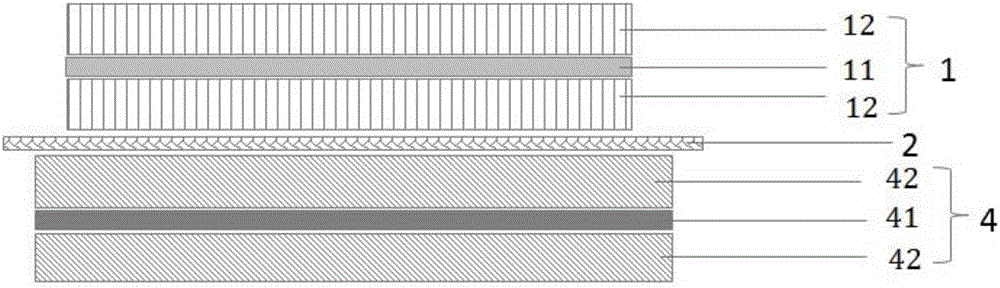

[0057] The cathode active material LiCoO 2 , binder PVDF, and conductive carbon (SP) are dissolved in the solvent N-methylpyrrolidone (NMP) according to the mass ratio of 96:2:2 and stirred evenly to make a slurry, which is evenly coated on the positive electrode current collector 11 (aluminum foil) After drying, the positive electrode sheet 1 of the lithium ion battery is made, and after drying, a positive electrode film 12 with a thickness of 0.20 mm is formed, that is, a positive electrode sheet without a lithium supplementary layer 3 is obtained, such as figure 2 shown;

[0058] Then, the lithium metal powder was mixed according to 0.10mg / cm 2 Sprinkle on the surface of the prepared positive electrode film 12, and then roll to form the positive electrode lithi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com