Lithium ion battery anode lithium supplement pole piece and preparation method thereof

A technology of lithium-ion batteries and negative pole pieces, applied in battery electrodes, non-aqueous electrolyte battery electrodes, secondary batteries, etc., can solve problems such as capacity fading, achieve the effects of reducing contact area, facilitating operation, and improving absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

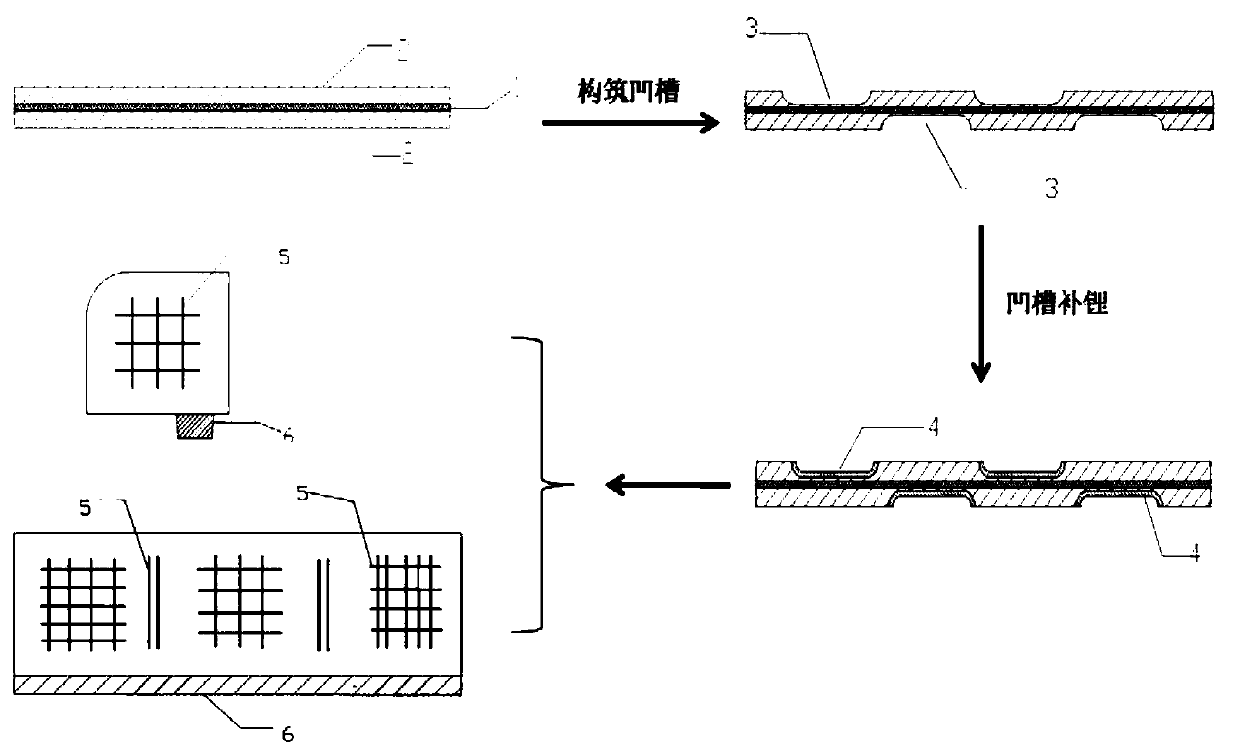

[0029] The preparation method of the present invention is carried out according to the following steps:

[0030] (1) Prepare a negative electrode slurry with a solid content of 49% by mixing silicon oxide-graphite composite powder, conductive agent carbon black, and binder polyvinylidene fluoride with the solvent methyl pyrrolidone at a mass ratio of 96:1.6:2.4 , evenly coated on 8μm-thick copper foil, and then made into negative electrode roll material through drying, rolling, and slitting processes.

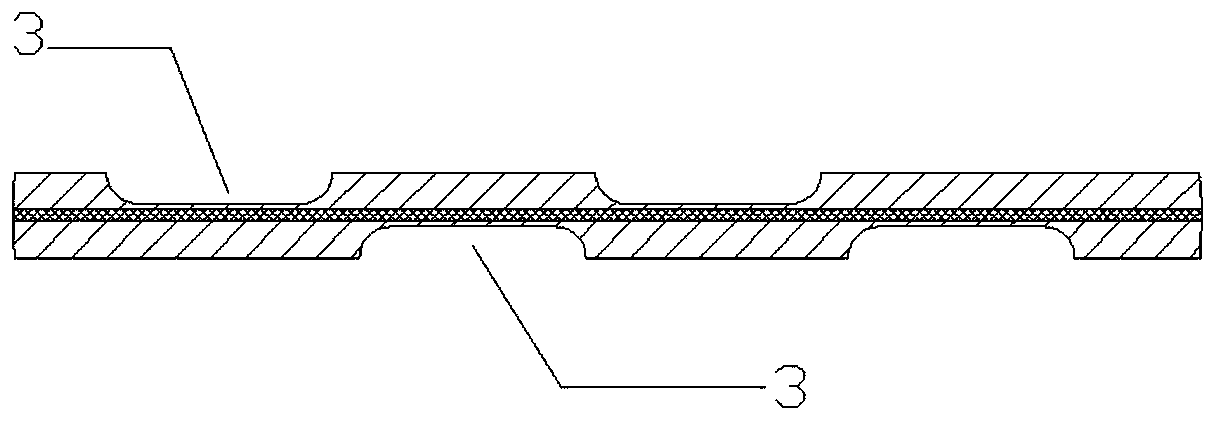

[0031] (2) The negative electrode sheet with a thickness of 132 μm (the active material coating thickness is 62 μm) is treated with a pulsed laser to construct a double-sided micro-groove structure on the upper and lower surfaces of the electrode sheet. During the process, the parameters are set as laser power 50W, scanning speed 10000mm / s, and the groove depth is about 42μm, and the width is 35μm.

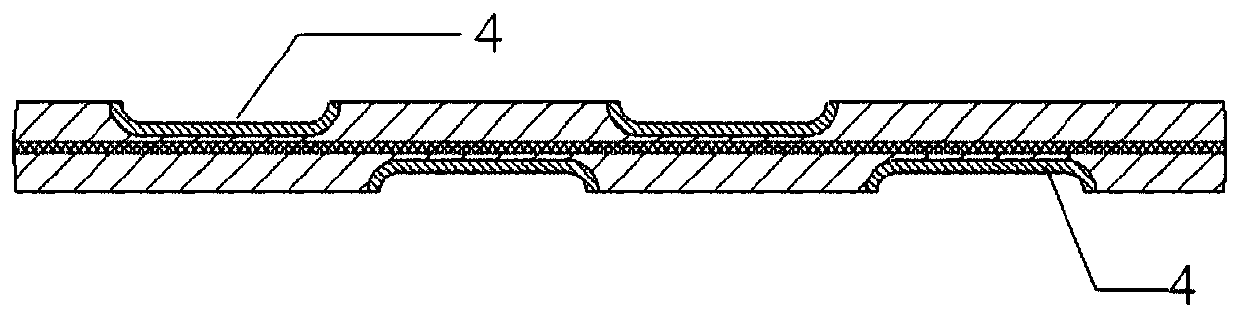

[0032] (3) A lithium layer with a thickness of 10 μm is filled in the groove ...

Embodiment 2

[0036] The preparation method of the present invention is carried out according to the following steps:

[0037] Step (1) is identical with embodiment 1

[0038] (2) The negative electrode sheet with a thickness of 132 μm (the active material coating thickness is 62 μm) is treated with a pulsed laser to construct a double-sided micro-groove structure on the upper and lower surfaces of the electrode sheet. During the process, the parameters are set as laser power 50W, scanning speed 10000mm / s, and the groove depth is about 42μm, and the width is 35μm.

[0039] (3) Only the grooves on the upper surface of the pole piece are filled with a lithium layer with a thickness of 12 μm.

[0040] (4) Obtain a negative electrode sheet with a lithium-supplementing micro-groove structure.

[0041] The obtained negative pole piece, ceramic separator, and positive pole piece obtained with the lithium-supplementing micro-groove structure are processed into a lithium-ion battery through proces...

Embodiment 3

[0043] The preparation method of the present invention is carried out according to the following steps:

[0044] Step (1), (2) are identical with embodiment 1

[0045] (3) Fill the groove with a thickness of 12 μm only on the winding non-bending part of the surface of the pole piece.

[0046] (4) Obtain a negative electrode sheet with a lithium-supplementing micro-groove structure.

[0047] The obtained negative pole piece, ceramic separator, and positive pole piece obtained with the lithium-supplementing micro-groove structure are processed into a lithium-ion battery through processes such as assembly, liquid injection, and chemical formation.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com