Preparation method of high-power lithium iron phosphate material

A lithium iron phosphate, high-power technology, applied in electrical components, battery electrodes, circuits, etc., can solve the problems of restricting the industrialization development of materials, high energy consumption, long time, etc., and achieve excellent product quality stability and power performance. Good, loose synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] A method for preparing a high-power lithium iron phosphate material is characterized in that the preparation steps include:

[0034] ⑴Preparation of liquid-phase rapid gelation precursor

[0035] ①According to the ratio of molar ratio lithium:iron:phosphorus=0.99-1.02:1:1, put the soluble lithium source compound, iron source compound and phosphorus source compound in the mixer, and stir at the speed of 200-1400 rpm , to form a mixed solution; add the dispersant to the mixed solution at a ratio of 5%-25% of the volume of the mixed solution and continue stirring, then add ammonia water to the mixer to adjust the pH value, and reduce the stirring speed of the mixer to below 8% of the initial speed ;Turn to 20-140 rpm, stop stirring; form a gelatinous mixture in the mixer;

[0036] ②Place the colloidal mixture in step ⑴①in a vacuum drying oven, and dry at 60°C-120°C for 4-12 hours to obtain a light yellow foam as a liquid-phase rapid gelling precursor;

[0037] ⑵ Pre-burn...

Embodiment 1

[0048] ⑴Preparation of liquid-phase rapid gelation precursor

[0049] ① Using lithium hydroxide, ferric nitrate and phosphoric acid as solute and water as solvent, respectively prepare lithium hydroxide transparent solution with lithium hydroxide content of 1.2mol / L and ferric nitrate transparent solution with ferric nitrate content of 2.2mol / L solution and a phosphoric acid transparent solution with a phosphoric acid content of 2mol / L; then put lithium hydroxide transparent solution, ferric nitrate transparent solution and phosphoric acid transparent solution into a mixer according to the molar ratio lithium: iron: phosphorus = 0.99:1:1, to mix Add Tween-80 dispersant to the mixed solution at 20% of the volume content of the solution; stir the lithium hydroxide transparent solution, ferric nitrate transparent solution, phosphoric acid transparent solution and Tween-80 dispersant at a speed of 700 rpm To form a uniform mixed solution, add ammonia water to the mixed solution, a...

Embodiment 2

[0060] ⑴Preparation of liquid-phase rapid gelation precursor

[0061] ① Using lithium acetate, ferric nitrate and phosphoric acid as solute and water as solvent, respectively prepare lithium acetate transparent solution with lithium acetate content of 2mol / L, ferric nitrate transparent solution with ferric nitrate content of 1.5mol / L and phosphoric acid content Phosphoric acid transparent solution of 2.5mol / L; then according to the molar ratio of lithium: iron: phosphorus = 1.02:1:1 lithium acetate transparent solution, iron nitrate transparent solution and phosphoric acid transparent solution are placed in the mixer, and the volume content of the mixed solution is Add 5% Tween-80 dispersant to the mixed solution; stir the lithium acetate transparent solution, ferric nitrate transparent solution, phosphoric acid transparent solution and Tween-80 dispersant into a uniform mixed solution at a speed of 200 rpm , add ammonia water in the mixed solution, adjust the pH value in the ...

PUM

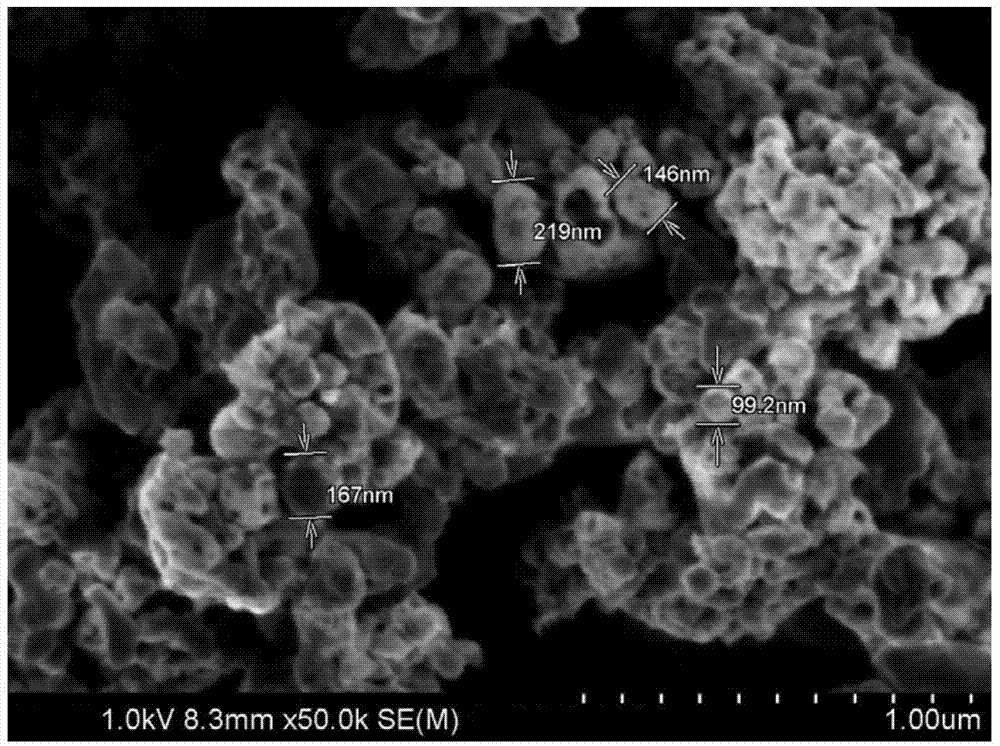

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com