Preparation method of high-activity lithium carbonate

A technology of lithium carbonate and high activity, applied in lithium carbonate; highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

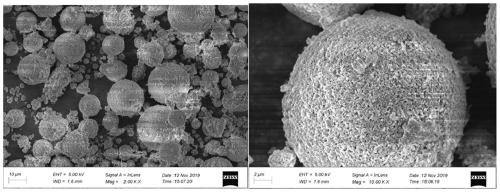

Image

Examples

Embodiment 1

[0035] A kind of preparation method of highly active lithium carbonate, it is the following steps:

[0036] (1) Lithium salt is mixed with lithium solution, and lithium concentration is 10g / L, prepares alkali solution, and the concentration of alkali solution is 9mol / L, prepares ammonium bicarbonate solution, and the concentration of ammonium bicarbonate is 180g / L;

[0037] (2) Convectively add the lithium solution, alkali solution, and ammonium bicarbonate solution into the reaction kettle, add the bottom liquid into the reaction kettle, maintain the pH value of the solution during the convective addition process, and the convective addition time is 60min, and continue the reaction after the addition is completed 2h, the temperature of the entire convective addition process and reaction process is 55°C;

[0038] (3) After the reaction is completed, filter, wash until the conductivity of the washing water is less than or equal to 100 μS / cm, then dry, and use microwave drying f...

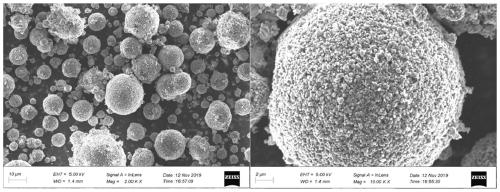

Embodiment 2

[0050] A kind of preparation method of highly active lithium carbonate, it is the following steps:

[0051] (1) Lithium salt is mixed with lithium solution, and lithium concentration is 22g / L, prepares alkali solution, and the concentration of alkali solution is 9mol / L, prepares ammonium bicarbonate solution, and the concentration of ammonium bicarbonate is 200g / L;

[0052] (2) Convectively add the lithium solution, alkali solution, and ammonium bicarbonate solution into the reaction kettle, add the bottom liquid into the reaction kettle, maintain the pH value of the solution at 11.5 during the convective addition process, and the convective addition time is 50min, and continue the reaction after the addition is completed 2h, the temperature of the entire convective addition process and reaction process is 55°C;

[0053] (3) After the reaction is completed, filter, wash until the conductivity of the washing water is less than or equal to 100 μS / cm, then dry, and use microwave ...

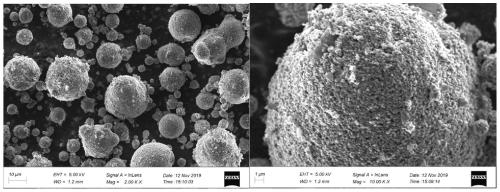

Embodiment 3

[0065] A kind of preparation method of highly active lithium carbonate, it is the following steps:

[0066] (1) Lithium salt is mixed with lithium solution, and lithium concentration is 18g / L, prepares alkali solution, and the concentration of alkali solution is 8mol / L, prepares ammonium bicarbonate solution, and the concentration of ammonium bicarbonate is 190g / L;

[0067] (2) Convectively add the lithium solution, alkali solution, and ammonium bicarbonate solution into the reaction kettle, add the bottom liquid into the reaction kettle, maintain the pH value of the solution at 10.9 during the convective addition process, and the convective addition time is 40min, and continue the reaction after the addition is completed 2h, the temperature of the entire convective addition process and reaction process is 55°C;

[0068] (3) After the reaction is completed, filter, wash until the conductivity of the washing water is less than or equal to 100 μS / cm, then dry, and use microwave ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com