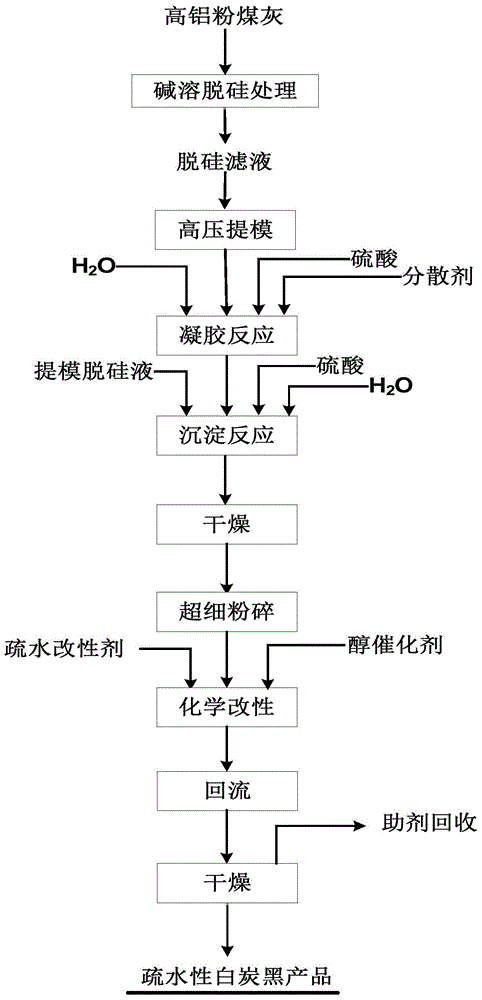

Method for preparing hydrophobic white carbon black by using high-alumina fly ash

A high-alumina fly ash, hydrophobic technology, applied in the direction of silicon dioxide, silicon oxide, etc., can solve the problems of small product range, high operating cost, high economic cost, inhibiting premature agglomeration, increasing specific surface area, widening Effects in the field of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) Using high-alumina fly ash as raw material, the content of alumina is 40-50%, and the desilication solution is obtained by carrying out alkali-soluble desiliconization reaction between high-alumina fly ash and alkali solution; the concentration of alkali solution is 80g / L , the solid content of fly ash is 40wt%. Heat the mixed material to 85°C, react at this temperature for 90min, and obtain a desiliconization solution with a modulus of 0.4 through refining, filtration and separation;

[0022] (2) Pressure mould-lifting of fly ash alkali-soluble desiliconization solution: put the fly ash alkali-soluble desiliconization solution in a pressure reactor for mold-lifting reaction, and obtain a mold-lifting desiliconization solution with a modulus within the range of 2.5;

[0023] (3) Preparation of reaction solution: add purified water to the desiliconization solution prepared in step (2), that is, water with conductivity ≤ 10us / cm, and prepare Na 2 An aqueous solution w...

Embodiment 2

[0028] (1) Using high-alumina fly ash as raw material, the content of alumina is 40-50%, and the desilication solution is obtained by carrying out alkali-soluble desiliconization reaction between high-alumina fly ash and alkali solution; the concentration of alkali solution is 120g / L , the solid content of fly ash is 30wt%. Heat the mixed material to 120°C, react at this temperature for 55min, and obtain a desiliconization solution with a modulus of 1.2 after refining, filtration and separation;

[0029] (2) Pressure mould-lifting of fly ash alkali-soluble desiliconization solution: put the fly ash alkali-soluble desiliconization solution in a pressure reactor for mold-lifting reaction, and obtain a mold-lifting desiliconization solution with a modulus within the range of 2.7;

[0030] (3) Preparation of reaction solution: add purified water to the desiliconization solution prepared in step (2), that is, water with conductivity ≤ 10us / cm, and prepare Na 2 An aqueous solution w...

Embodiment 3

[0035] (1) Using high-alumina fly ash as raw material, the content of alumina is 40-50%, and the desilication solution is obtained by carrying out alkali-soluble desiliconization reaction between high-alumina fly ash and alkali solution; the concentration of alkali solution is 100g / L , the solid content of fly ash is 30wt%. Heat the mixed material to 110°C, react at this temperature for 30min, and obtain a desiliconization solution with a modulus of 0.8 after refining, filtration and separation;

[0036] (2) Pressure mould-lifting of fly ash alkali-soluble desiliconization liquid: put the fly ash alkali-soluble desiliconization liquid in a pressure reactor for mold lifting reaction, and obtain a mould-lifting desiliconization liquid with a modulus within the range of 2.3;

[0037] (3) Preparation of reaction solution: add purified water to the desiliconization solution prepared in step (2), that is, water with conductivity ≤ 10us / cm, and prepare Na 2 An aqueous solution with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com