Preparation method of lithium iron phosphate/double carbon layer coated composite material

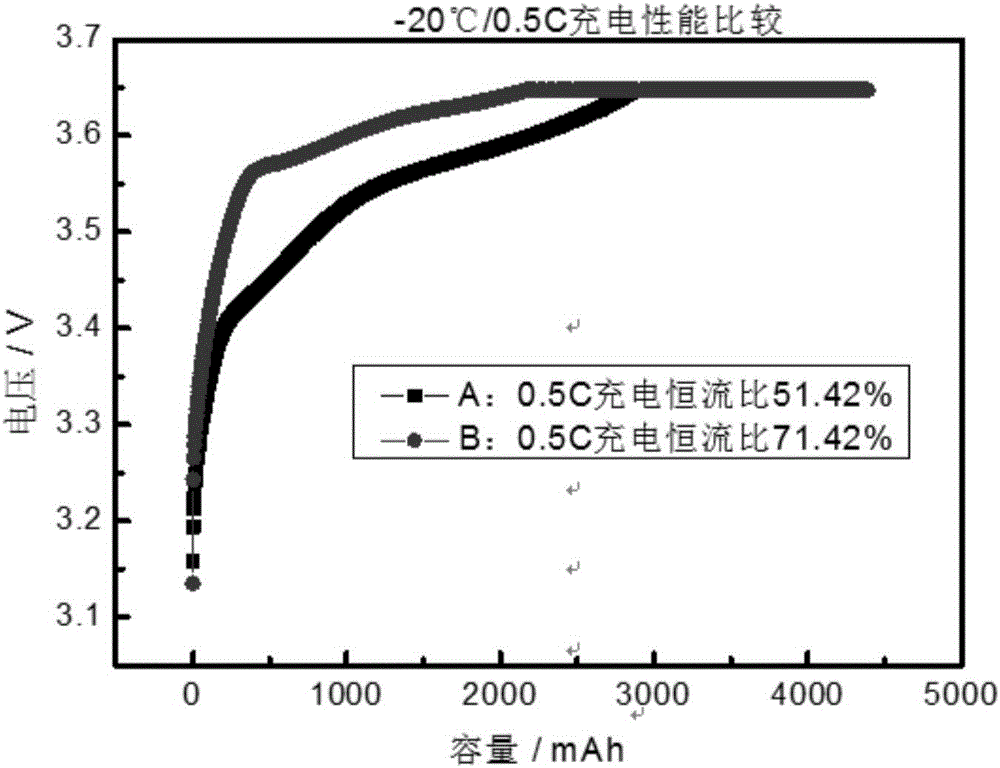

A technology of lithium iron phosphate and composite materials, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of low carbon content, unsatisfactory electronic conductivity of materials, and difficulties, so as to increase the secondary particle size and shorten the The effect of beating aging and improving electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The invention provides a method for preparing a lithium iron phosphate / double carbon layer coated composite material, comprising the following steps:

[0030] Step 1: Prepare iron source, phosphorus source and lithium source with a certain material ratio, mix evenly, add reducing agent and dissolve, then add mesoporous carbon (CMK-3), and perform ultrasonic stirring to obtain the first mixed solution ;

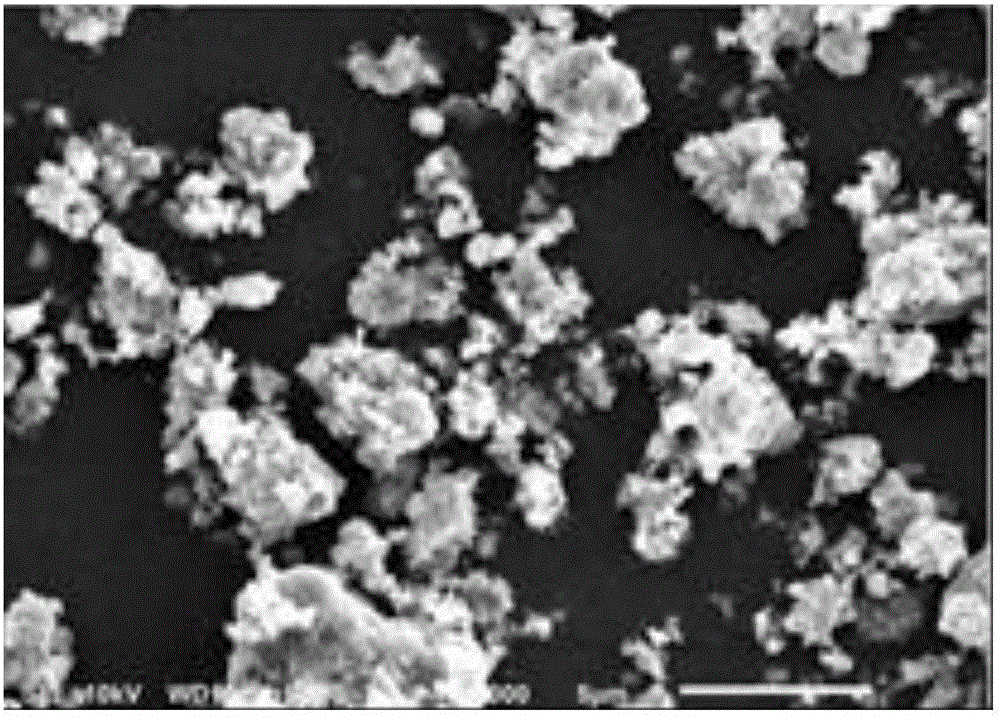

[0031] Step 2: Transfer the first mixed solution obtained in Step 1 to the reaction kettle, carry out hydrothermal reaction, cool to room temperature after the reaction, wash and dry the reaction product to obtain a lithium iron phosphate / carbon-doped composite Material;

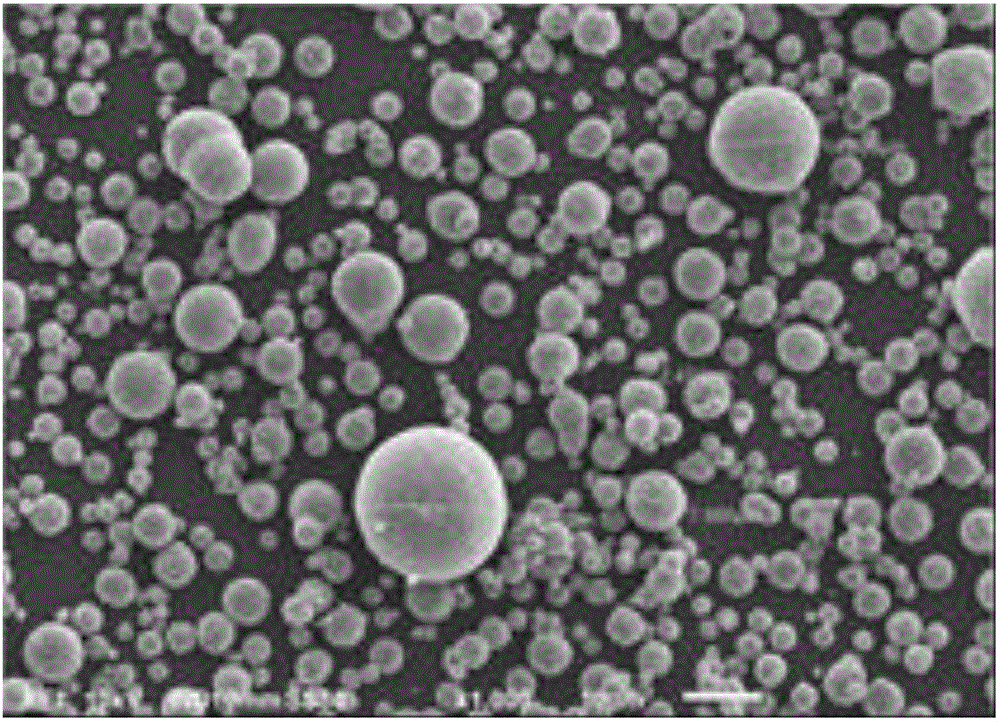

[0032] Step 3: Place the lithium iron phosphate / carbon-doped composite material obtained in step 2 in a tube furnace under the protection of an inert gas. After the first high-temperature calcination, take it out after cooling, wash and dry to obtain the primary Lithium iron phosphate / double carbon ...

Embodiment 1

[0047] 1. The concentration ratio of the prepared substance is 1:1:3 FeSO 4 ·H 2 O, H 3 PO 4 Mix equal volumes of LiOH and LiOH into a beaker, add 1.8g glucose under magnetic stirring, add 1.25g mesoporous carbon CMK-3 after dissolution, and stir ultrasonically for 30min to make it evenly dispersed.

[0048] 2. Transfer the uniformly dispersed solution obtained in step 1 to a reaction kettle, conduct a hydrothermal reaction at 130°C for 8 hours, cool to room temperature after the reaction, wash the reaction product, and dry it by blasting to obtain a lithium iron phosphate / carbon doped composite material .

[0049] 3. Place the lithium iron phosphate / carbon-doped composite material obtained in step 2 in a tube furnace, under the protection of nitrogen, calcinate at 750°C for 2 hours, take it out after cooling, wash with deionized water and absolute ethanol several times, The primary lithium iron phosphate / double carbon layer clad composite material is obtained by drying. ...

Embodiment 2

[0052] 1. The concentration ratio of the prepared substance is 1:1:3 FeSO 4 ·H 2 O, H 3 PO 4 Mix equal volumes of LiOH and LiOH into a beaker, add 2.1g citric acid under magnetic stirring, add 1.50g mesoporous carbon CMK-3 after dissolution, and ultrasonically stir for 30min to make it evenly dispersed.

[0053] 2. Transfer the uniformly dispersed solution obtained in step 1 to a reaction kettle, conduct a hydrothermal reaction at 150°C for 10 hours, cool to room temperature after the reaction, wash the reaction product, and dry it with air to obtain a lithium iron phosphate / carbon doped composite material .

[0054] 3. Put the lithium iron phosphate / carbon-doped composite material obtained in step 2 in a tube furnace, under the protection of nitrogen, calcinate at 750°C for 4 hours, take it out after cooling, wash with deionized water and absolute ethanol several times, Dry the lithium iron phosphate / double carbon layer cladding composite material.

[0055] 4. Weigh 1.8g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com