Fine pigment composition and manufacturing method thereof

A technology of pigment composition and manufacturing method, which is applied in the direction of chemical instruments and methods, anthracene dyes, azo dyes, etc., can solve problems such as inaccessibility, and achieve the effects of preventing aggregation, inhibiting aggregation, and small primary particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

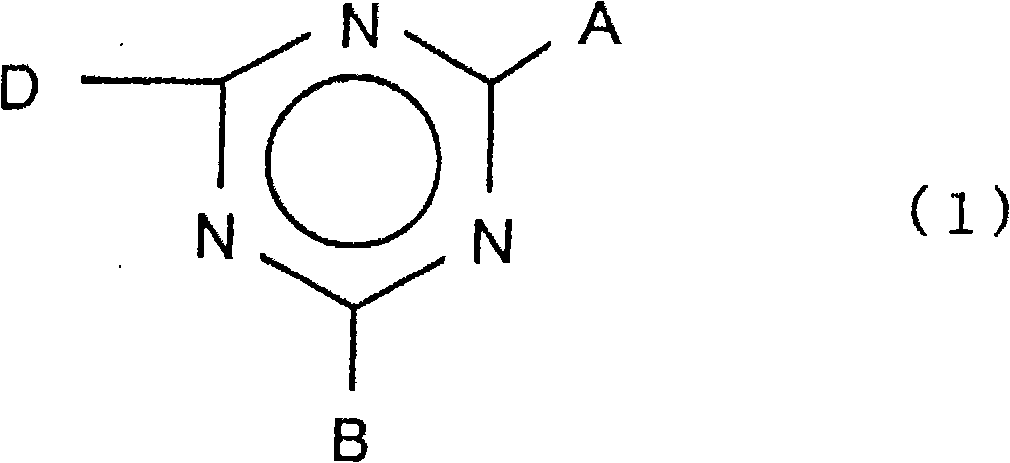

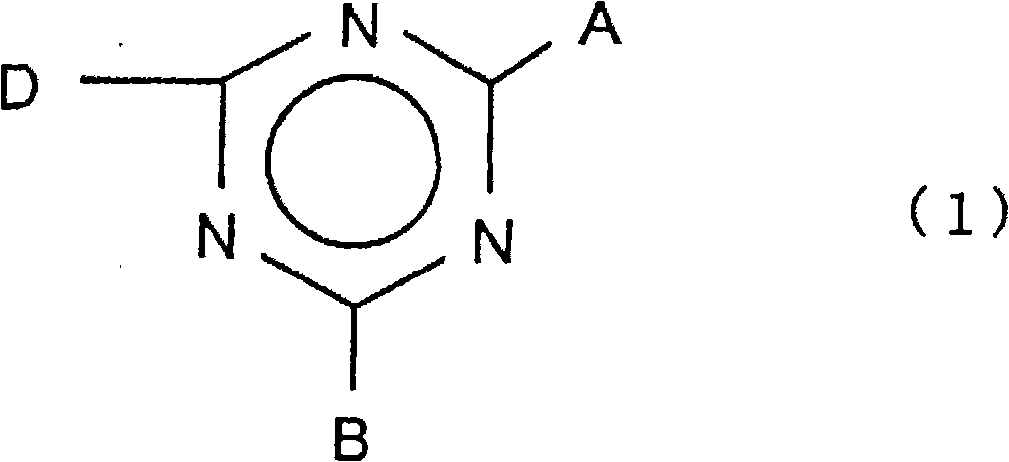

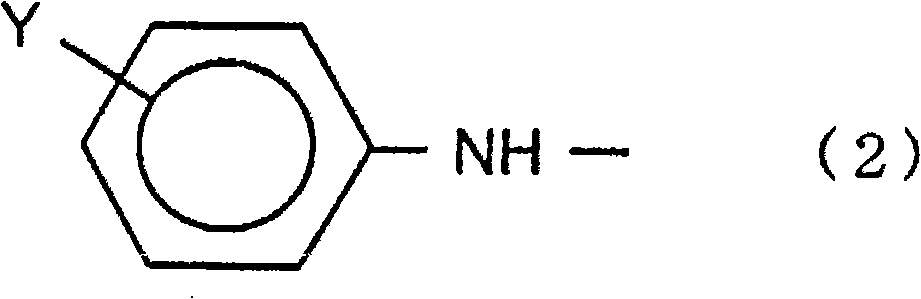

[0081] In 100 parts of water, add 7.3 parts of cyanuric chloride (Cyanuric chloride) and 6.8 parts of p-aminobenzenesulfonic acid (trade name: ASASulfanilic acid, Sugai Chemical IND.CO ., LTD. production), reacted at 20°C for 1 hour. Next, 10 parts of 4,4'-methylene-bis-2,6-xylaniline (trade name: KAYABOND C-200S, produced by Nippon Kayaku) in an amount that reacts with one Cl of the reactant was added, React at 70°C for 1 hour. After the obtained reactant was filtered and the residue was washed with water, it was left to stand overnight in a thermostat at 80° C., and dried to obtain 17.0 parts of a triazine compound represented by the above formula (10).

manufacture example 2

[0083] Except having added 3.4 parts of p-aminobenzenesulfonic acid instead of 6.8 parts of p-aminobenzenesulfonic acid, it carried out similarly to manufacture example 1, and obtained 14.8 parts of triazine compounds represented by said formula (11).

manufacture example 3

[0085] Add 4.3 parts of p-phenylenediamine (trade name: p-phenylene diamine, produced by Wako Pure Chemical Industries) to replace 10 parts of 4,4'-methylene-two-2,6-xylidine, in addition, carry out and In the same manner as in Production Example 1, 12.5 parts of the triazine compound represented by the above formula (12) were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com