Preparing method of wrapping type phosphate ferromanganese

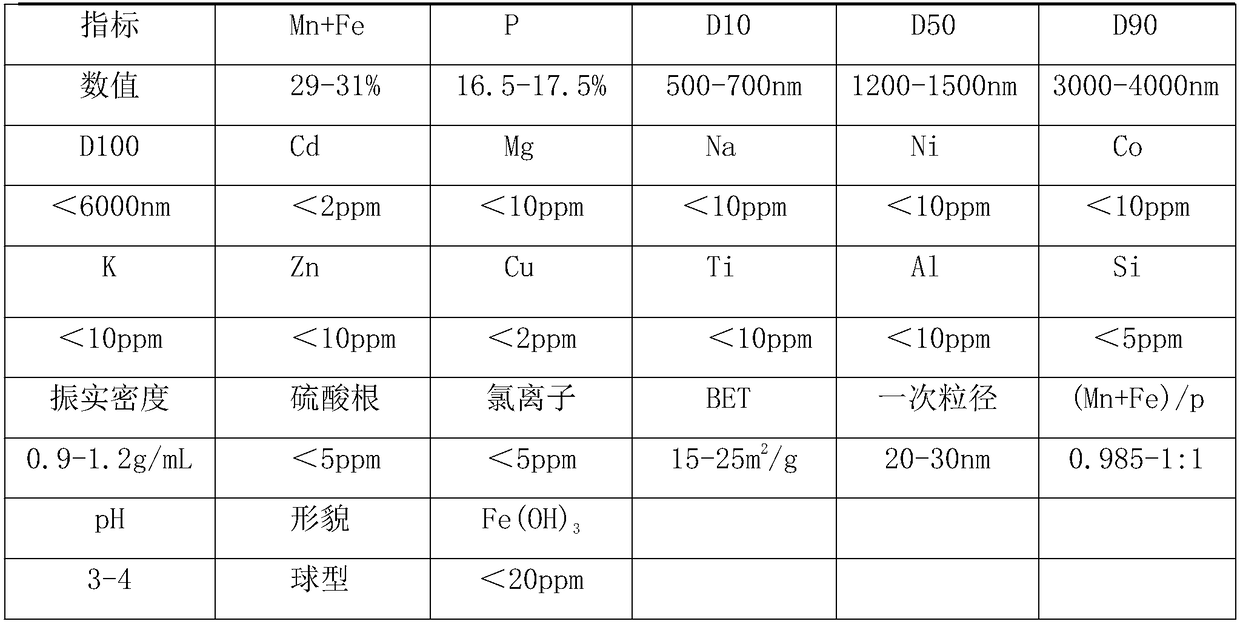

A ferromanganese phosphate, coated technology, applied in chemical instruments and methods, phosphorus compounds, nanotechnology for materials and surface science, etc. The effect of low chloride ion content, uniform particle size distribution and low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

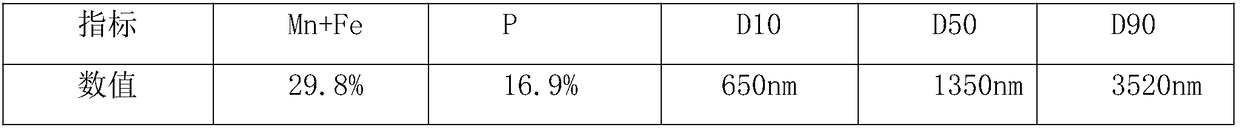

Embodiment 1

[0037] A preparation method of coated ferromanganese phosphate, which comprises the following steps:

[0038] (1) Pretreatment, add ferromanganese alloy powder to phosphoric acid, stir and react at a temperature of 63°C until the ferromanganese alloy powder is completely dissolved, and at the same time control the pH of the solution after the dissolution is complete to 1.72, then filter, add the filtrate to hydrogen peroxide, and add the time During the addition process, the temperature was maintained at 35°C. After the addition was completed, the temperature was raised to 93°C, and the reaction was stirred for 2.5 hours at a stirring speed of 420r / min to obtain a ferric phosphate slurry;

[0039] (2) Add the ferric phosphate slurry obtained in step (1) into sodium dodecylbenzenesulfonate, then add manganese carbonate until the pH of the solution is 3.85, and at the same time make the manganese carbonate dissolve completely, and then continue at a temperature of 93°C Add hydro...

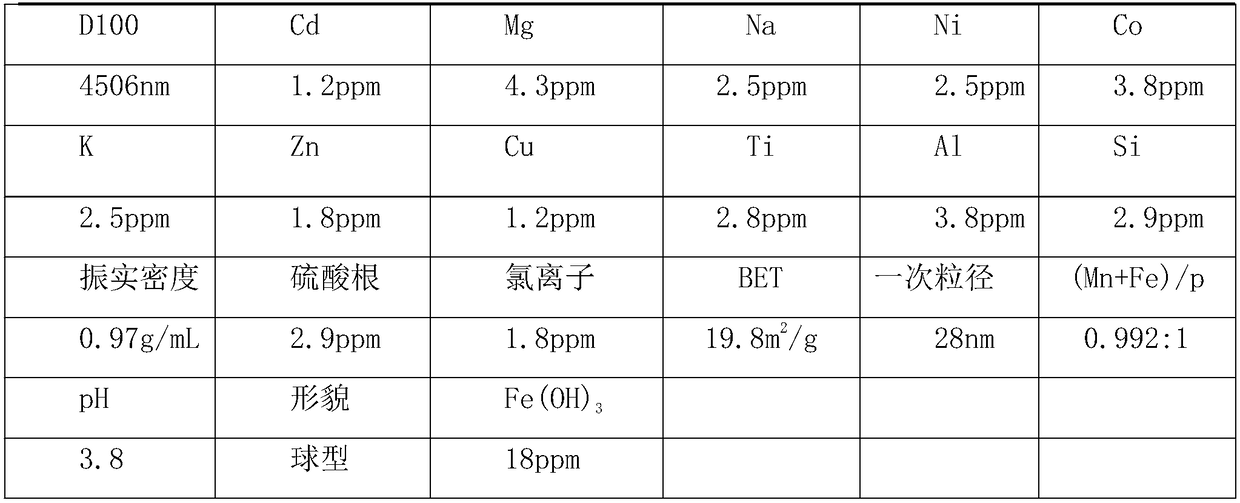

Embodiment 2

[0049] A preparation method of coated ferromanganese phosphate, which comprises the following steps:

[0050] (1) Pretreatment, add ferromanganese alloy powder to phosphoric acid, stir and react at a temperature of 68°C until the ferromanganese alloy powder is completely dissolved, and at the same time control the pH of the solution after the dissolution is complete to 1.76, then filter, add the filtrate to hydrogen peroxide, and add the time During the addition process, the temperature was maintained at 35°C. After the addition, the temperature began to rise to 93.5°C, and the reaction was stirred for 2.5 hours at a stirring speed of 450r / min to obtain a ferric phosphate slurry;

[0051] (2) Add the ferric phosphate slurry obtained in step (1) into sodium dodecylbenzenesulfonate, then add manganese carbonate until the pH of the solution is 3.85, and at the same time make the manganese carbonate dissolve completely, and then continue at a temperature of 92°C Add hydrogen perox...

Embodiment 3

[0060] A preparation method of coated ferromanganese phosphate, which comprises the following steps:

[0061] (1) Pretreatment, add ferromanganese alloy powder to phosphoric acid, stir and react at a temperature of 65°C until the ferromanganese alloy powder is completely dissolved, and at the same time control the pH of the solution after the dissolution is complete to 1.75, then filter, add the filtrate to hydrogen peroxide, and add the time During the addition process, the temperature was maintained at 35°C. After the addition was completed, the temperature was raised to 92.5°C, and the reaction was stirred for 2.5 hours at a stirring speed of 400r / min to obtain a ferric phosphate slurry;

[0062] (2) Add the ferric phosphate slurry obtained in step (1) into sodium dodecylbenzenesulfonate, then add manganese carbonate until the pH of the solution is 3.75, and at the same time make the manganese carbonate dissolve completely, and then continue at a temperature of 92.5°C Add h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com