Preparation method of metallic oxide with photocatalytic activity

A photocatalytic activity and oxide technology, applied in the field of photocatalytic materials, can solve the problems of material specific surface area reduction, high energy consumption, crystal size increase, etc., and achieve slow crystal growth rate, high specific surface area, and small primary particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

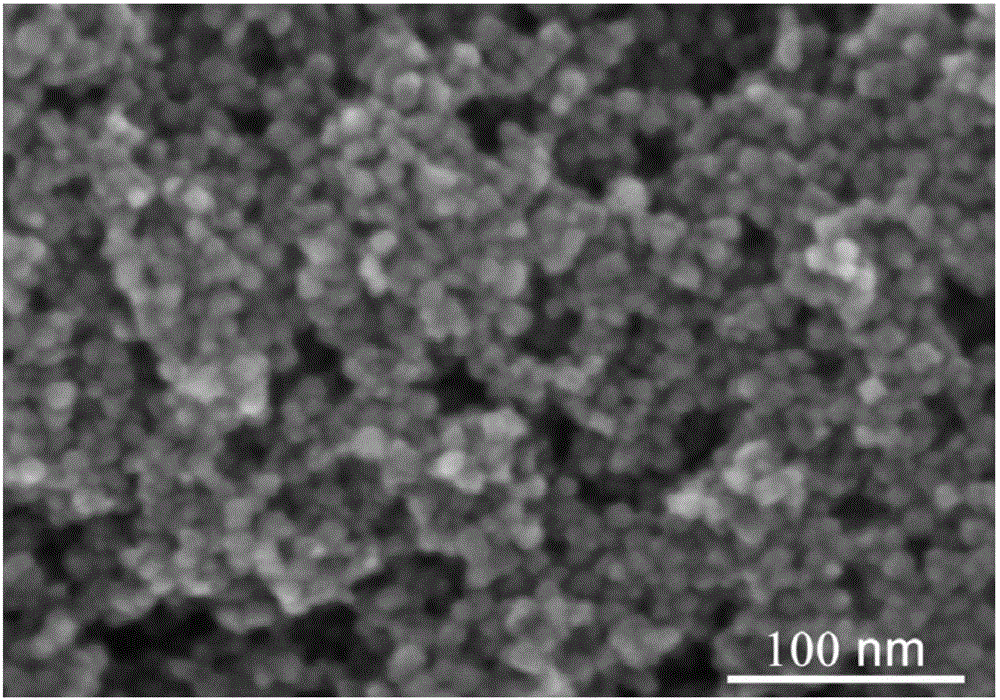

Image

Examples

preparation example Construction

[0024] The present invention provides a low-temperature preparation method of metal oxides with photocatalytic activity, wherein these metal oxides with photocatalytic activity are semiconductor materials with energy band structure and forbidden band, for example, they can be selected from titanium oxide, zinc oxide, One of tungsten oxide, tin oxide, palladium oxide, cuprous oxide, strontium titanate, aluminum titanate, barium titanate, etc. or a composite material formed by several of them. Some applications are accomplished by taking advantage of the electronic transition characteristics of these metal-semiconductor oxides under light irradiation.

[0025] The low-temperature preparation method of this photocatalytically active metal oxide comprises the following steps:

[0026] step one:

[0027] (1) Acquiring a metal precursor corresponding to the metal oxide.

[0028] For the selected metal oxide, some corresponding metal precursors are available, and some metal precurs...

Embodiment 1

[0045] 20 g of tetrabutyl titanate was added dropwise to 200 ml of deionized water, and continued to stir for 1 h. The obtained white precipitate of titanium hydroxide was centrifuged at 5000 r / min for 10 min, rinsed twice with ethanol, and purified titanium hydroxide was obtained.

[0046] Mix the purified titanium hydroxide with 160g of ethanol, add 1ml of 4mol / L nitric acid to adjust the pH, add 0.28g of ferric nitrate, stir and mix to form a dispersion. Then the dispersion liquid was transferred into a high-pressure airtight container, and kept at 160° C. for 10 h to obtain a reaction product. The reaction product was separated at 8000 r / min, washed twice with deionized water and then dried at 80° C. to obtain iron-doped titanium dioxide.

Embodiment 2

[0048] Same as Example 1, wherein the liquid medium is changed from ethanol to deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com