Surface mounting fuse protector and manufacturing method thereof

A surface mount and fuse technology, which is applied in the field of surface mount fuses and their manufacturing, can solve the problems of low production efficiency, reducing the consistency of fuse fusing characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

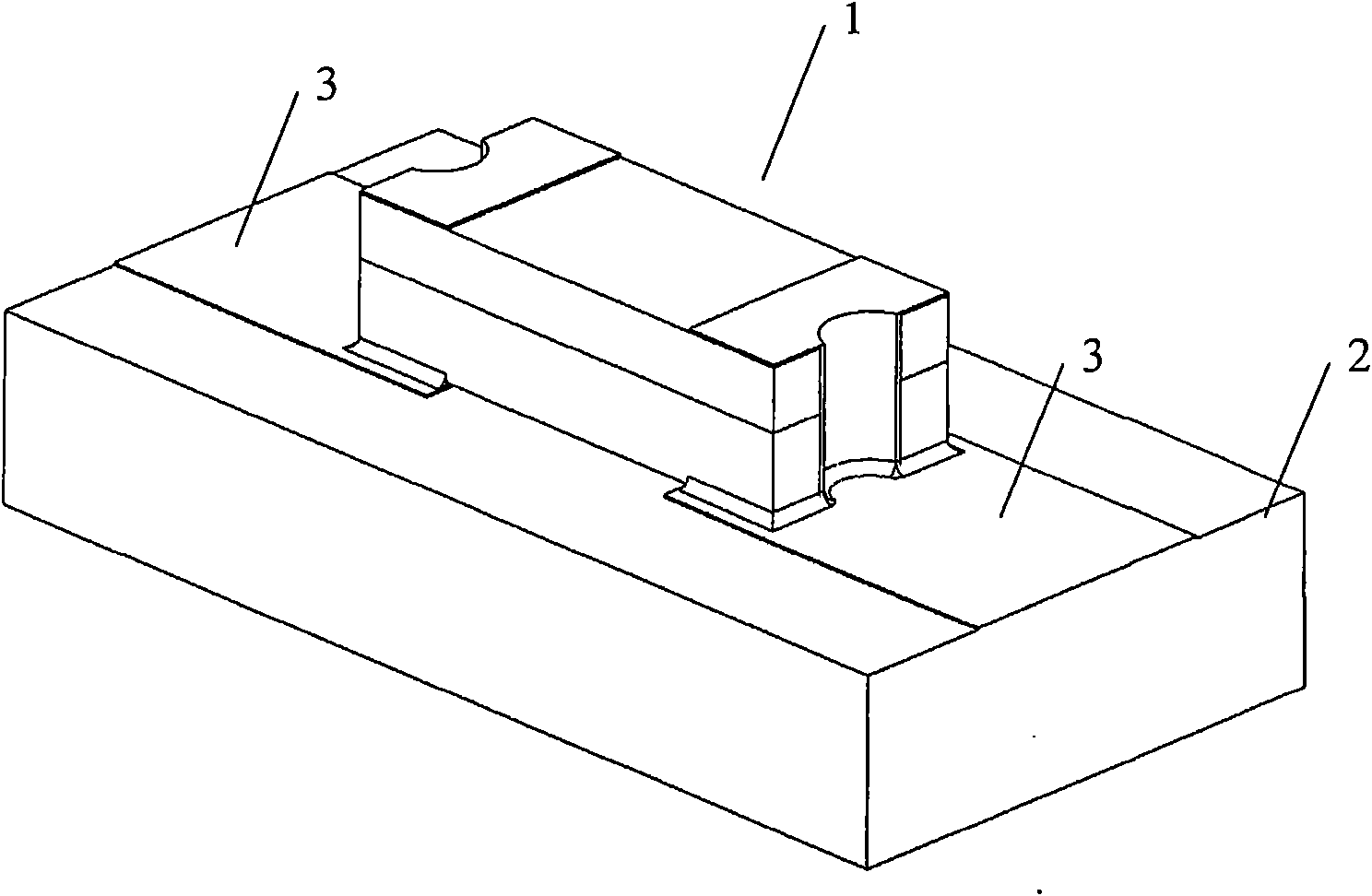

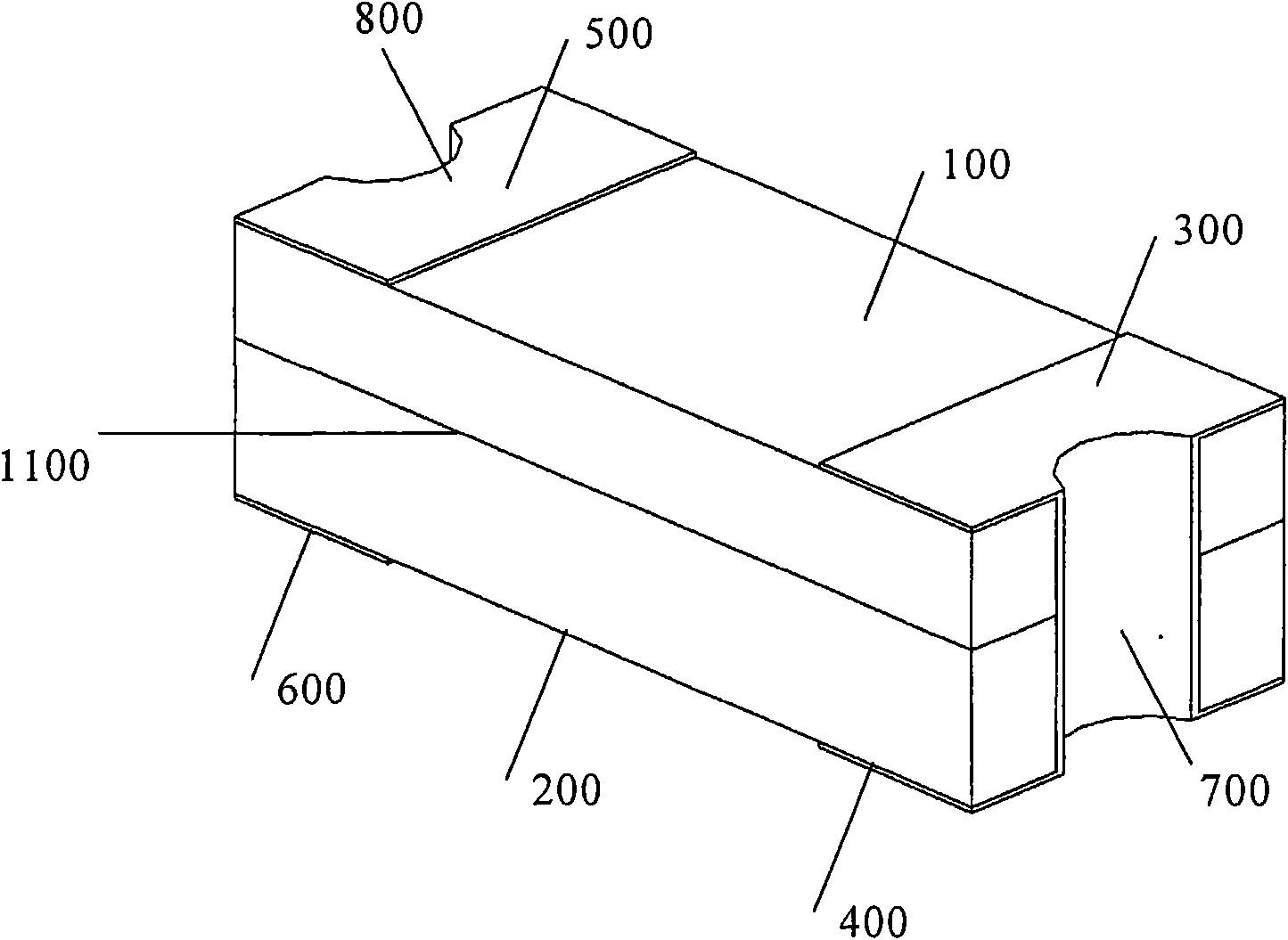

[0062] Manufacturing the above-mentioned fuse 1 of the present invention may include the following steps.

[0063] Prepare two insulating boards (polymer material boards such as thermoplastic or thermosetting plastics) as the upper and lower substrates 100, 200, and attach copper foil to both ends of one side of the substrate 100, 200 to form terminal electrodes 300, 500, 400, 600. It is also possible to prepare a substrate with copper foil attached to one side, and then use electrochemical corrosion or mechanical processing to remove part of the copper foil to form separate terminal electrodes 300, 500, 400, 600 at both ends. Certainly, the terminal electrodes 300, 500, 400, 600 may also be formed of other conductive materials.

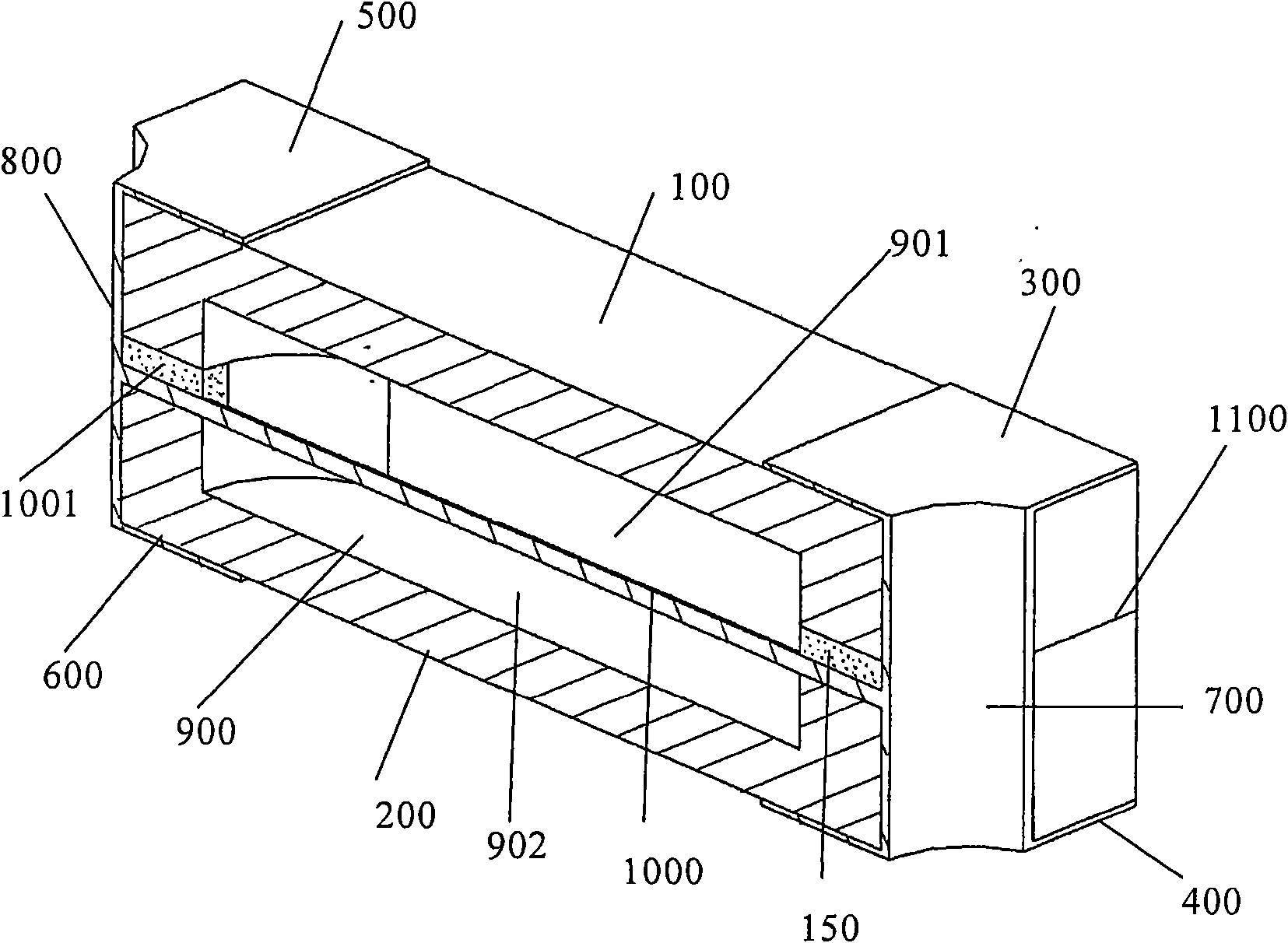

[0064] On the other sides of the upper and lower substrates 100, 200 where terminal electrodes are not formed, corresponding concave cavities 901, 902 are machined by mechanical means, such as milling, punching and the like.

[0065] On the side of...

Embodiment 2

[0071] see Figure 5-12 , multiple fuses 1 above can be processed at one time through two larger substrate materials.

[0072] The substrate material can be a single-sided printed circuit board substrate with a wide range of sources and low cost. This substrate is covered with a layer of copper foil on a polymer material. Of course, double-sided printed circuit boards can also be used after removing the copper foil on one side. Other thermoplastic or thermosetting plastics coated with copper foil or other layers of conductive material are also included in the available substrate materials.

[0073] see Figure 5 , 6 The copper foil 10 covered on the polymer material 11 of the substrate material is made into a terminal electrode pattern corresponding to the terminal electrode by means of electrochemical corrosion or mechanical processing. The terminal electrode pattern can be, for example, as Figure 5 , 6 Shown in parallel strips, other suitable shapes are possible as d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com