Triple cationic phosphorizing fluid containing calcium, zinc and manganese for steel plate and zinc-coated plate treatment

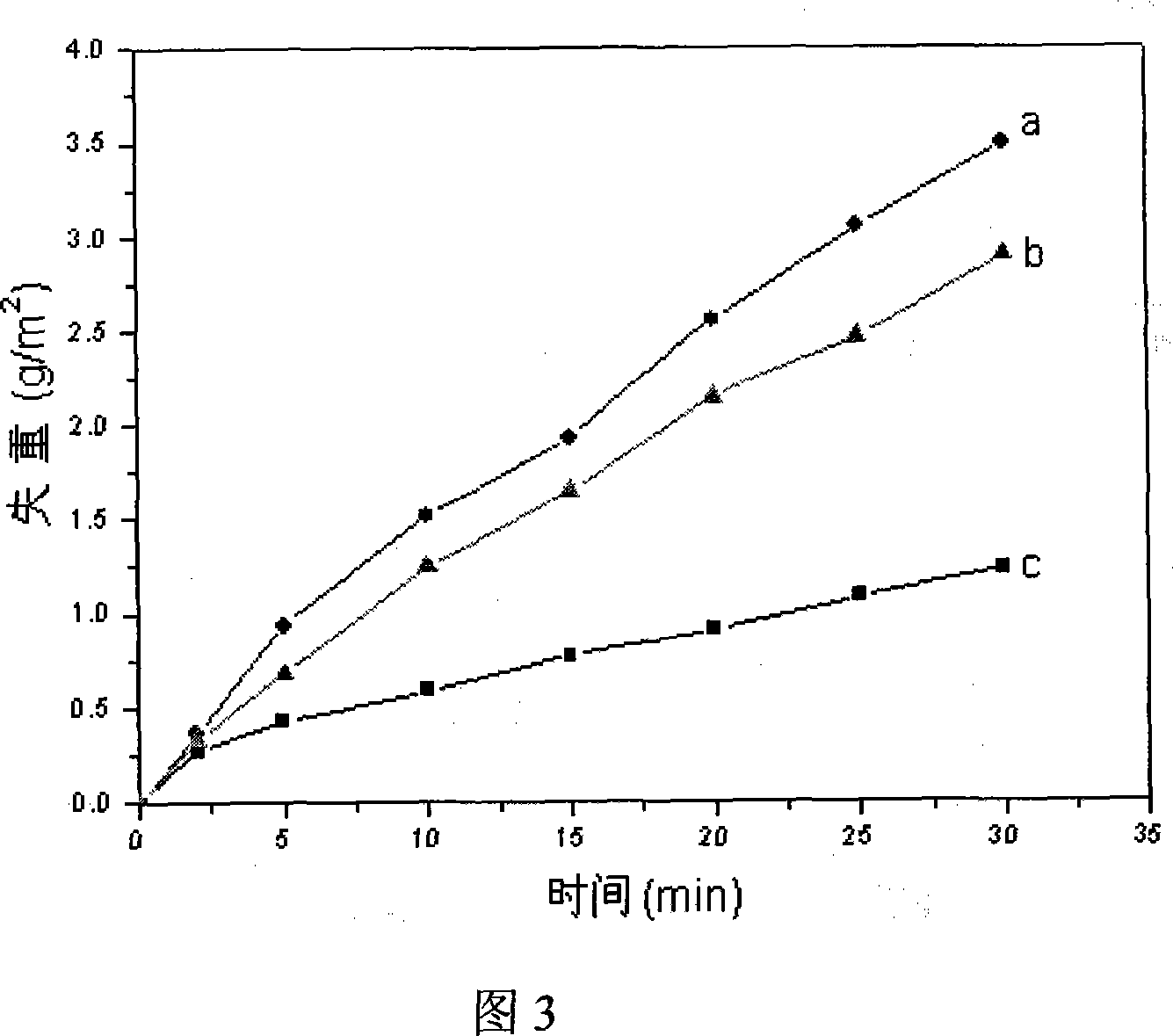

A zinc-manganese ternary cation and galvanized sheet technology, which is applied in the coating process of metal materials, can solve the problems of hexavalent chromium hazards and restrictions on the use of chromate, and achieve rapid formation, fine crystallization, and alkali resistance of the film layer sex high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

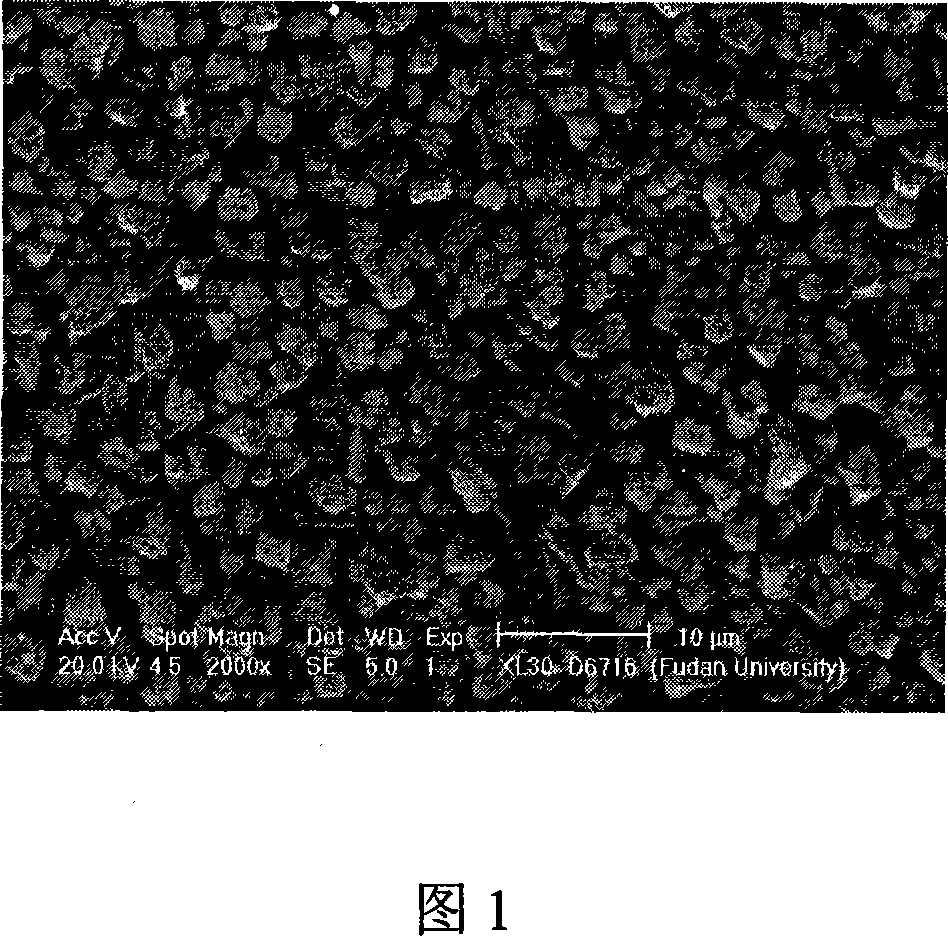

[0046] Embodiment 1: the phosphating solution is composed of, water is the solvent, 5 g of calcium nitrate, 10 g of manganese acetate, 2 g of zinc nitrate, 20 g of phosphoric acid or calcium dihydrogen phosphate, 5 g of sodium nitrate, and 10 g of accelerator citric acid are added in every liter of the phosphating solution ; When used for the surface treatment of electro-galvanized steel sheets, the pH value is 2-4, the temperature is 40-60°C, and the treatment time is 2-10 minutes, and a uniform and fine phosphating film can be formed on the galvanized steel sheets.

Embodiment 2

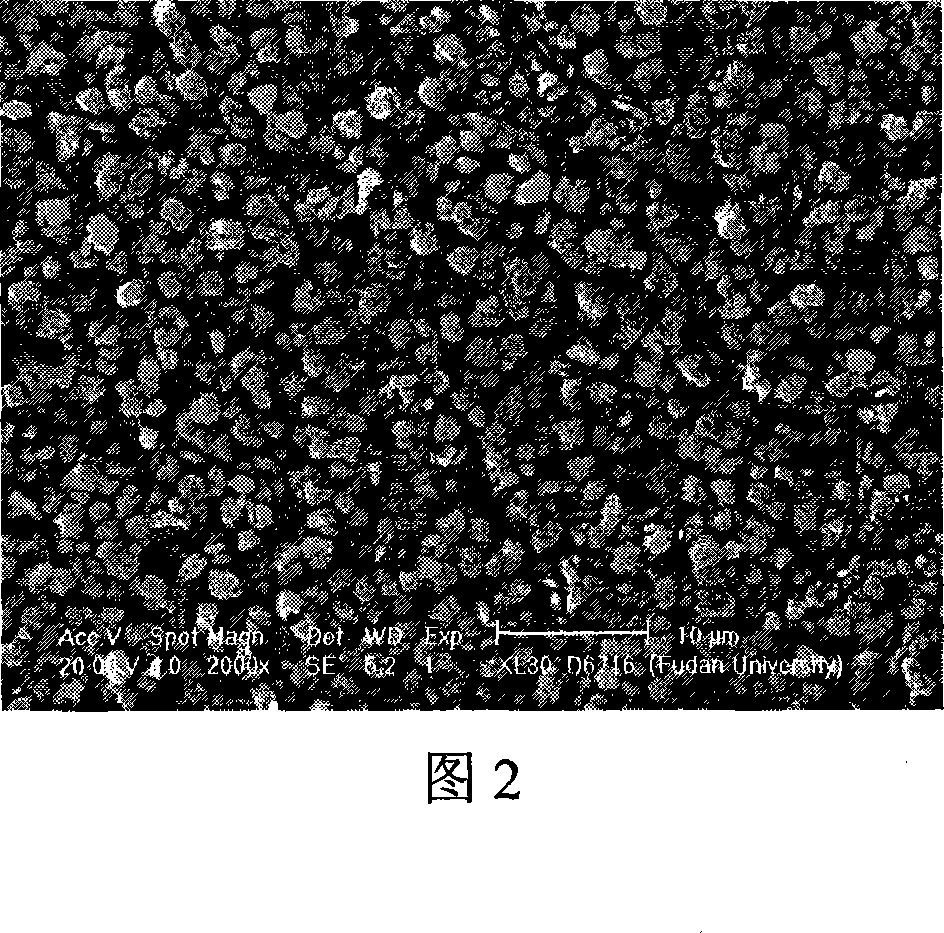

[0047] Embodiment 2: the phosphating solution is composed of, water is a solvent, calcium nitrate 60g is added in every liter of phosphating solution, manganese acetate 0.5g, zinc nitrate 35g, phosphoric acid or calcium dihydrogen phosphate 5g, sodium nitrate 30g, accelerator chloric acid Sodium 0.5g; when used for the surface treatment of electro-galvanized steel sheets, the pH value is 2-4, the temperature is 40-60°C, the sample is a steel plate, and the treatment time is 3-10 minutes, and a uniform phosphating film can be formed on the surface of the steel plate .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com