Preparation method for preparing manganese dioxides in various crystal forms

A technology of manganese dioxide and crystal form is applied in the field of preparation of nano-manganese dioxide of different crystal forms, which can solve the problems that the product is only one-dimensional and the calcination temperature is high, and achieves the effect of simple experimental process and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

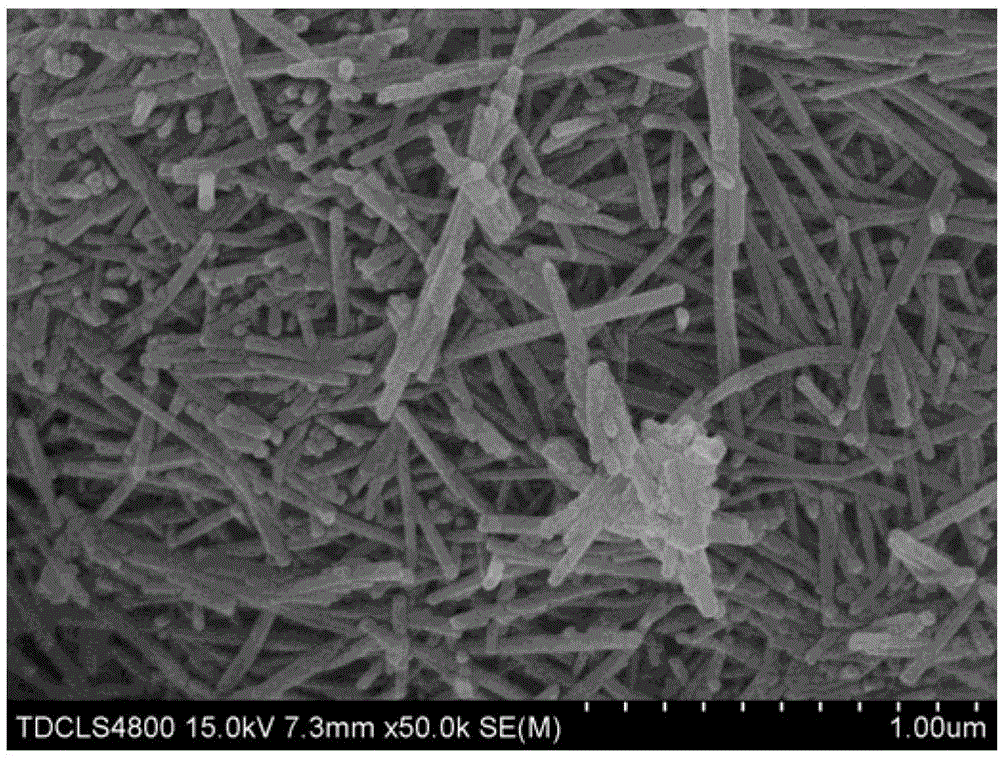

[0020] (1) Dissolve 608.4mg of manganese sulfate and 379.2mg of potassium permanganate in 5mL and 12mL of distilled water respectively, and stir to form a uniform solution;

[0021] (2) At room temperature, under the condition of stirring, add the potassium permanganate solution in step (1) into the manganese sulfate solution dropwise, and stir for 30 minutes;

[0022] (3) Transfer the reaction solution in step (2) to a reaction kettle, and react at 160°C for 6 hours. After the reaction, the product was collected by centrifugation and washed 5 times with distilled water and ethanol;

[0023] (4) Dry the product obtained in step (3) at 100°C for 8 hours to obtain α-MnO 2 Nanofibers.

[0024] The above obtained samples are made into electrodes: according to MnO 2 : Graphite: Acetylene black: PTFE The weight ratio is 70:12:12:6 Weigh 4 kinds of electrode materials and mix together, add 3mL of absolute ethanol, ultrasonically disperse for 10min. Pour all the uniformly mixed sl...

Embodiment 2

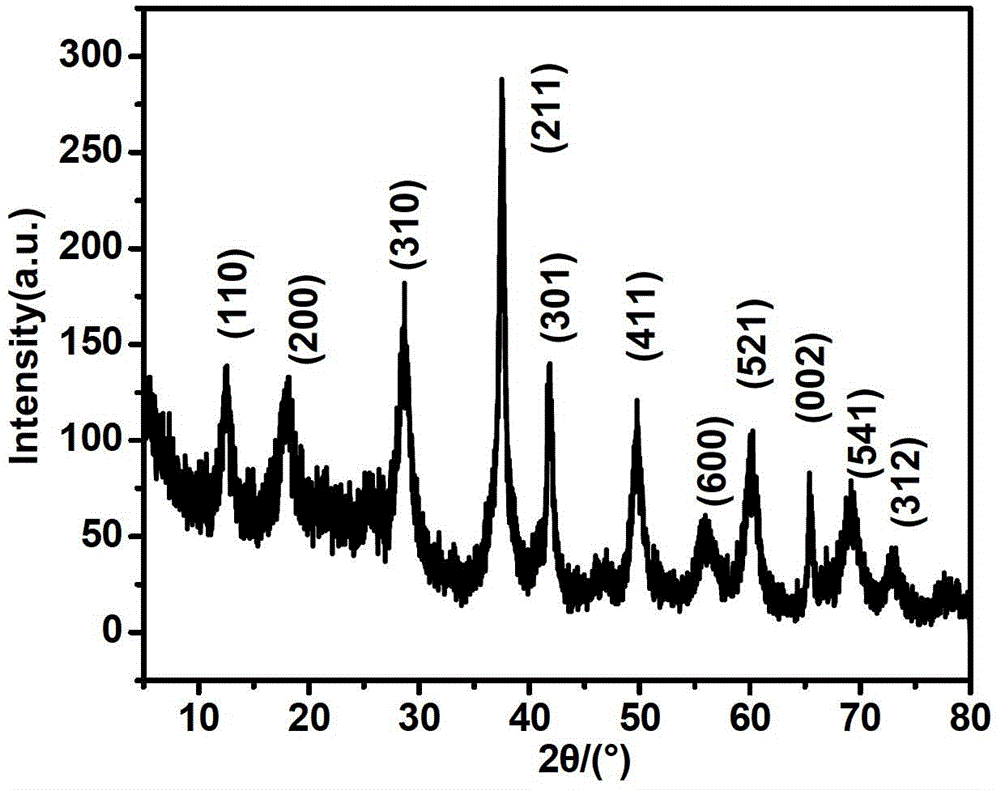

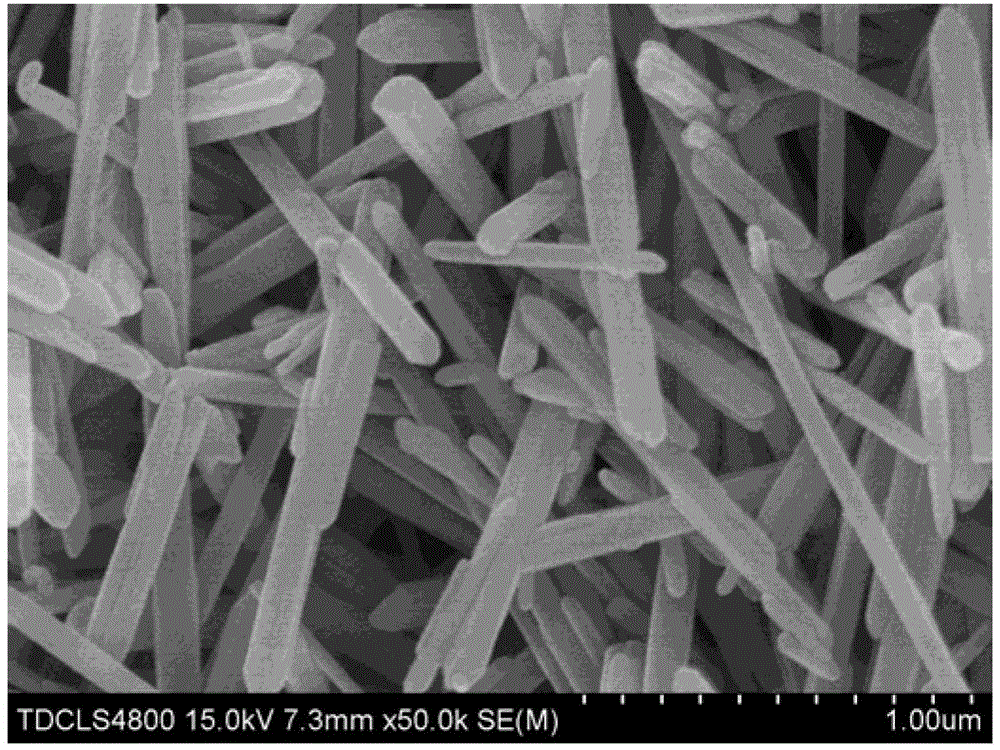

[0027] (1) Weigh 405.6mg of manganese sulfate and 126.4mg of potassium permanganate, dissolve them in 12mL and 4mL of distilled water, and stir to form a uniform solution;

[0028] (2) At room temperature, under the condition of stirring, add the potassium permanganate solution in step (1) dropwise into the manganese sulfate solution, and stir for 30 minutes.

[0029] (3) Transfer the reaction solution in step (2) to a reaction kettle, and react at 160°C for 6 hours. After the reaction, the product was collected by centrifugation and washed 6 times with distilled water and ethanol.

[0030] (4) Dry the product obtained in step (3) at 100°C for 8 hours to obtain β-MnO 2 Nano stave.

[0031] The above obtained sample is made into an electrode: by weight ratio MnO 2 : Graphite: Acetylene black: PTFE = 70:12:12:6 Weigh 4 kinds of electrode materials and mix them together, add 4mL of absolute ethanol, and ultrasonically disperse for 10min. Pour all the uniformly mixed slurry on...

Embodiment 3

[0034] (1) Dissolve 113mg of manganese sulfate and 632mg of potassium permanganate in 2mL and 15mL of distilled water respectively, and stir to form a uniform solution;

[0035] (2) At room temperature, under the condition of stirring, add the potassium permanganate solution in step (1) dropwise into the manganese sulfate solution, and stir for 30 minutes.

[0036] (3) Transfer the reaction solution in step (2) to a reaction kettle, and react at 160°C for 6 hours. After the reaction, the product was collected by centrifugation and washed 7 times with distilled water and ethanol;

[0037] (4) Dry the product obtained in step (3) at 100°C for 8 hours to obtain δ-MnO 2 Nanofibers.

[0038] The above obtained sample is made into an electrode: by weight ratio MnO 2 : Graphite: Acetylene black: PTFE=70:12:12:6 Weigh 4 kinds of electrode materials and mix together, add 5mL absolute ethanol, and disperse by ultrasonic for 10min. Pour all the uniformly mixed slurry on a stainless s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com