Preparation method of single-crystal Li(NiCoMn)O2 ternary cathode material

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied in the direction of chemical instruments and methods, electrical components, battery electrodes, etc., can solve the problems of resorcinol and formaldehyde, which are toxic and irritating, and achieve easy control of the process and improve Effects of improving energy density and cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of single crystal nickel cobalt lithium manganese oxide ternary positive electrode material, the specific steps are:

[0032] 1) 2.98g Ni(CH 3 COO) 2 4H 2 O, 1.00g Co(CH 3 COO) 2 4H 2 O and 0.98g Mn(CH 3 COO) 2 4H 2 O, dissolve in 80mL deionized water and ethylene glycol mixed solution (volume ratio 1:1), stir evenly, add 1.5g CTAB after it is completely dissolved, add 2.65g oxalic acid after it is completely dissolved, stir until completely well mixed.

[0033] 2) Transfer the homogeneous mixture obtained in step 1) to a stainless steel reaction kettle, seal it, place it in a blast drying oven, and react at 200°C for 10 hours;

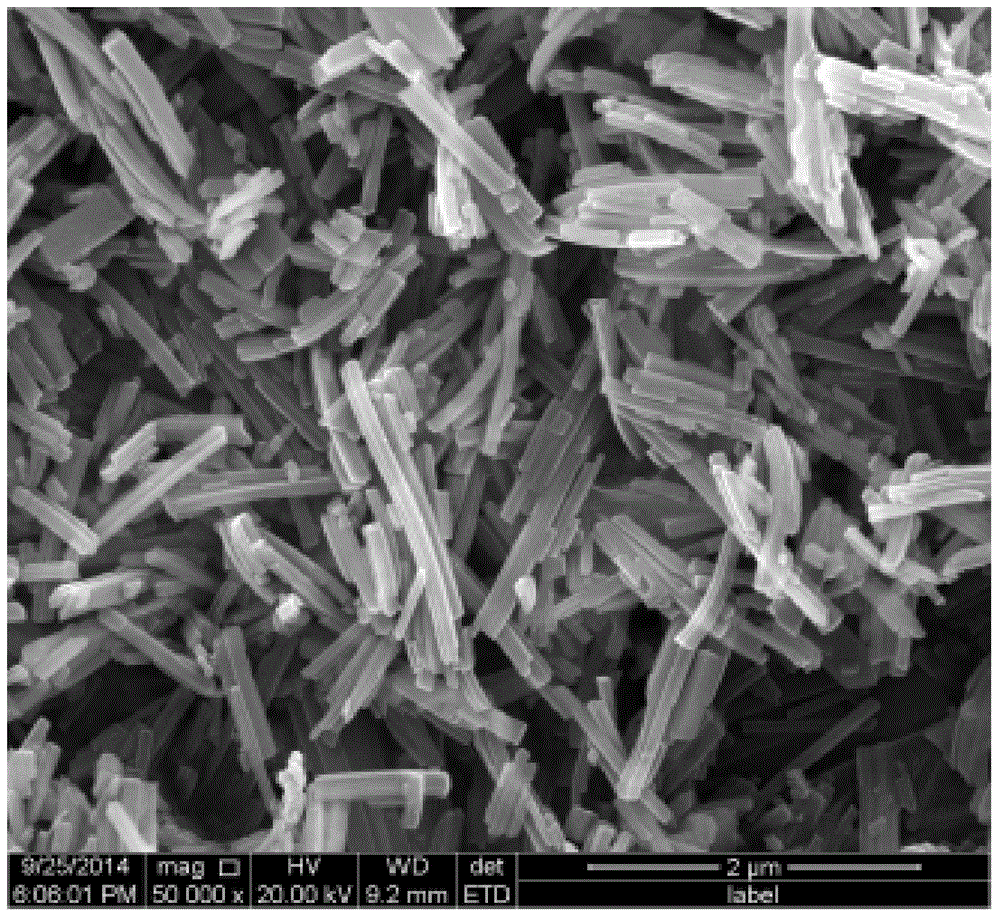

[0034] 3) After the reaction, take out the reactor and cool it down to room temperature, centrifuge the precursor solution in the reactor for 5 times, then place it in a blast drying oven, and dry it at 80°C for 24 hours to obtain the precursor. Its SEM morphology is as follows figure 1 shown;

[0035] 4) Add 0.81...

Embodiment 2

[0040] A preparation method of single crystal nickel cobalt lithium manganese oxide ternary positive electrode material, the specific steps are:

[0041] Step is identical with the step in embodiment 1, difference is that in step 4) the LiNO of 0.81g 3 Add it to 2g of the precursor in step 3), and after grinding and mixing, place it in an air-atmosphere pre-calcination furnace for pre-calcination, with a heating rate of 5°C / min to a pre-fire temperature of 450°C, and constant temperature pre-fire for 10 hours , cooled to room temperature to obtain the oxide. Then place the oxide in a calciner for high-temperature calcination. The temperature rises at a rate of 10°C / min to 500°C. After 10 hours of constant temperature, the temperature is raised to 700°C at 10°C / min. ℃, calcined for 24h, and cooled to room temperature at 10℃ / min to obtain LiNi 0.6 co 0.2 mn 0.2 o 2 Ternary cathode material with a mass of about 1.9g.

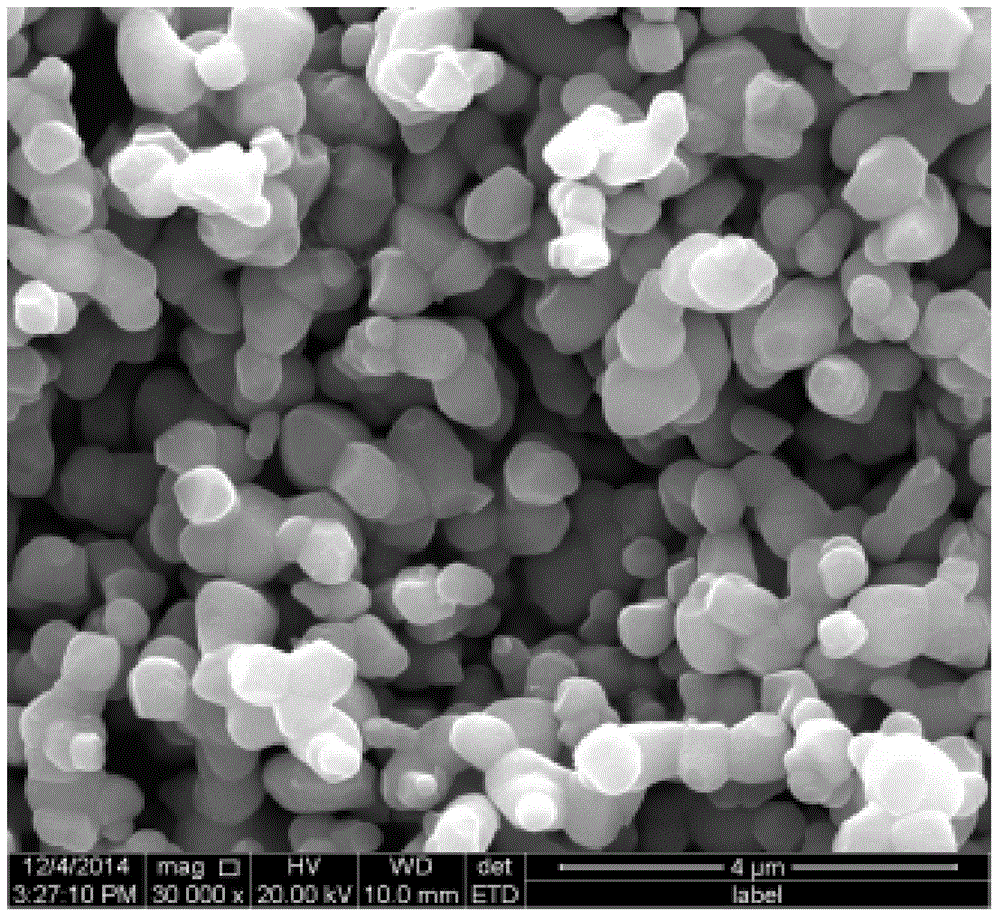

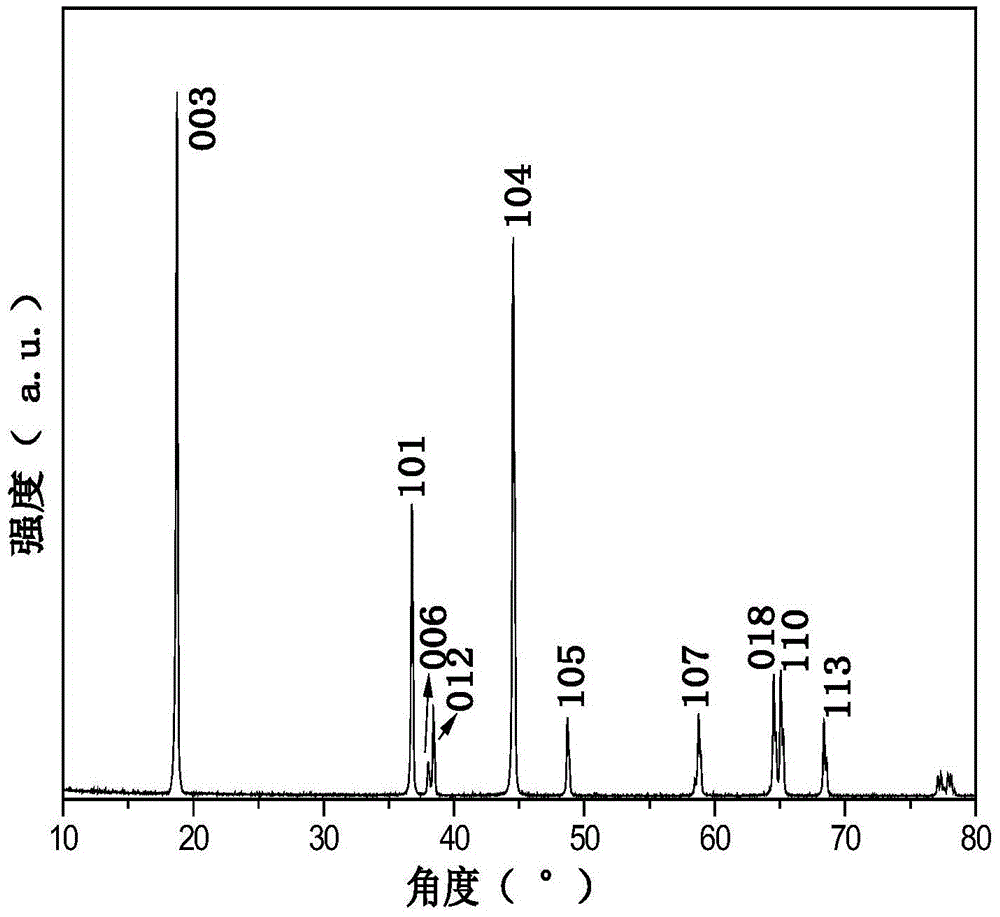

[0042] Will get LiNi 0.6 co 0.2 mn 0.2 o 2 The X-ra...

Embodiment 3

[0046] A method for preparing a single crystal nickel-cobalt lithium manganese oxide ternary positive electrode material, the specific steps are:

[0047] 1) 1.23g NiCO 3 , 0.41g CoCO 3 and 0.40g MnCO 3 , dissolve in 80mL deionized water and ethylene glycol mixed solution (volume ratio 1:2), stir well, add 1.5g CTAB after it is completely dissolved, add 2.65g oxalic acid after it is completely dissolved, stir until completely mixed .

[0048] 2) Transfer the homogeneous mixture obtained in step 1) to a stainless steel reaction kettle, seal it, place it in a blast drying oven, and react at 220° C. for 6 hours;

[0049] 3) After the reaction, take out the reaction kettle and cool it to room temperature, centrifuge the precursor solution in the reaction kettle for 5 times, then place it in a blast drying oven, and dry it at 80°C for 24 hours to obtain the precursor;

[0050] 4) Add 0.81g of LiNO 3 Add it to 2g of the precursor in step 3), after grinding and mixing, place it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com