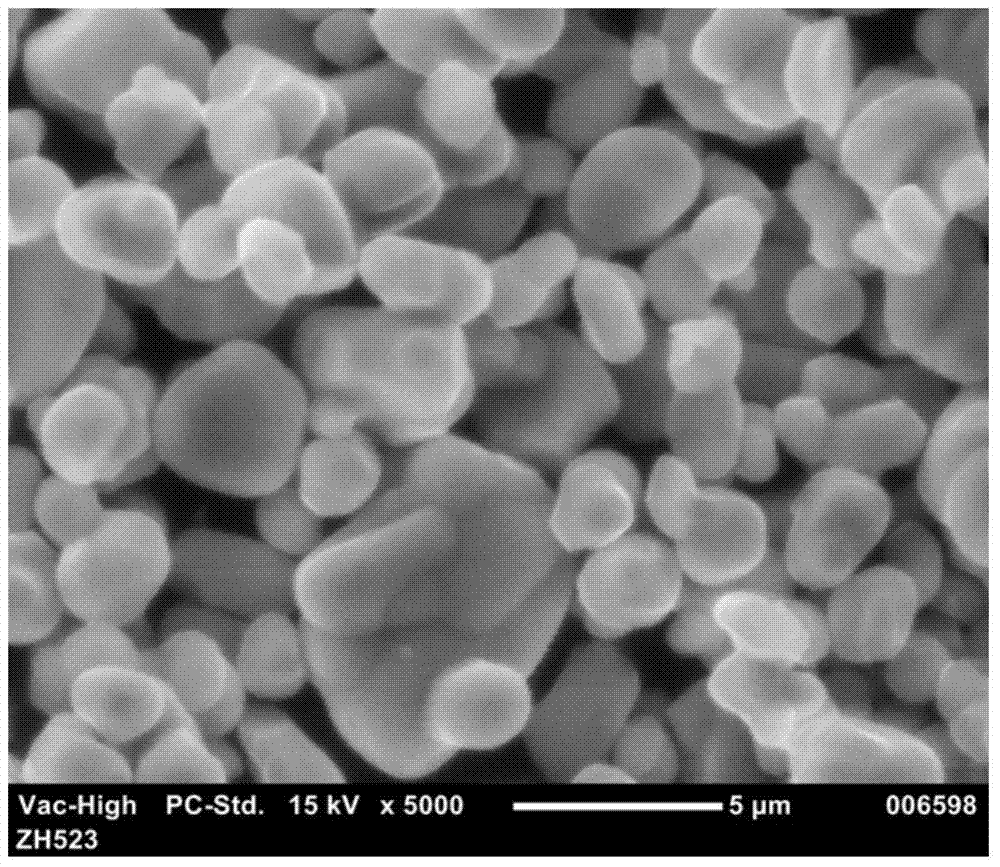

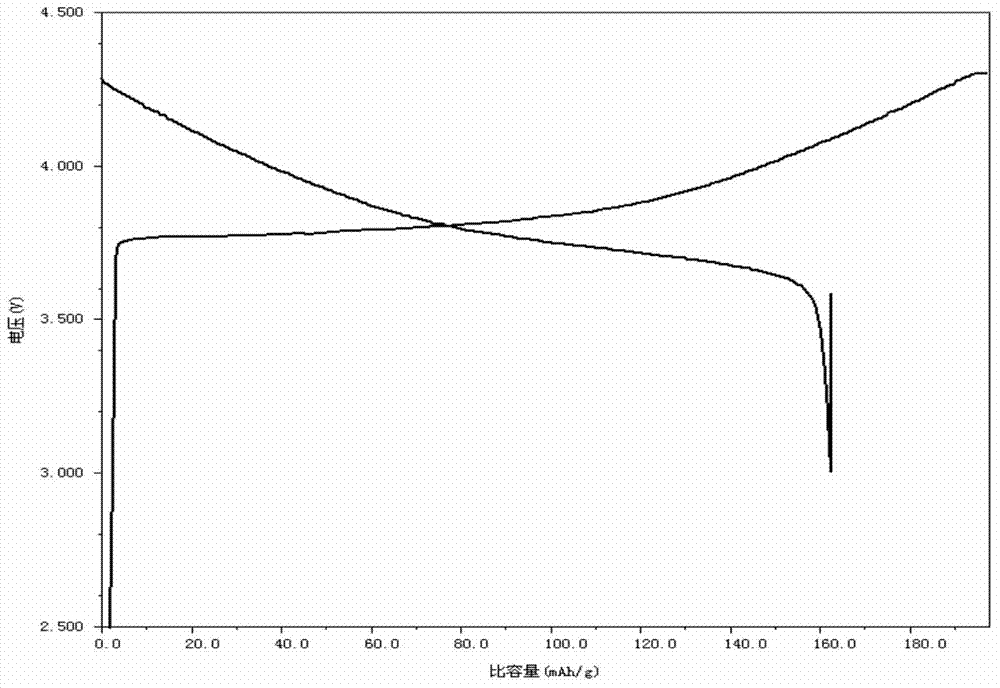

Preparation method of high density nickel cobalt lithium manganate positive electrode material

A technology of nickel-cobalt lithium manganese oxide and positive electrode materials, which is applied to battery electrodes, electrical components, circuits, etc., can solve the problems of low material processing performance and low energy density, and achieve low production costs, good rate performance, and preparation methods simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] ①According to the ion molar ratio nickel Ni:cobalt Co:manganese Mn=0.5:0.2:0.3 to prepare a mixed solution with a concentration of 180g / L, nickel sulfate, cobalt sulfate and manganese sulfate are used to prepare the nickel cobalt manganese solution.

[0027] ② Prepare 150g / L sodium hydroxide solution with pure water.

[0028] ③ Prepare 2mol / L ammonia water with liquid ammonia.

[0029] Prepare the bottom solution containing ammonia water, control the pH value at 10.15, the concentration of ammonia water is 6g / L, the temperature is 62°C, the stirring speed is 120r / min, and the metering pumps of ① solution, ② solution, and ③ solution are simultaneously fed, and turned on Solid content regulating valve, when the solid content is controlled at 160g / L, open the overflow discharge valve, pass through the particle size analyzer during the precipitation reaction, and observe the spherical shape with a microscope. The feeding time is 2h, the temperature is 55°C, and the pH is c...

Embodiment 2

[0034] ① Prepare a mixed solution with a concentration of 180g / L according to the ion molar ratio Ni: Co: Mn = 1:1:1. Nickel sulfate, cobalt chloride, and manganese sulfate are used to prepare the nickel-cobalt-manganese solution.

[0035]② Prepare 150g / L sodium hydroxide solution with pure water.

[0036] ③ Prepare 2mol / L ammonia water with liquid ammonia.

[0037] Prepare the bottom solution containing ammonia water, control the pH value at 11.15, the concentration of ammonia water is 8g / L, the temperature is 58°C, the stirring speed is 150r / min, and the metering pumps of ① solution, ② solution, and ③ solution are fed simultaneously, and turn on Solid content regulating valve, when the solid content is controlled at 500g / L, open the overflow discharge valve, pass through the particle size analyzer during the precipitation reaction, and observe the spherical shape with a microscope. The feeding time is 2h, the temperature is 55°C, and the pH is controlled at 11.5. After the ...

Embodiment 3

[0040] ① Prepare a mixed solution with a concentration of 180g / L according to the ion molar ratio Ni: Co: Mn = 0.4:0.2:0.4. Nickel sulfate, cobalt chloride, and manganese sulfate are used to prepare the nickel-cobalt-manganese solution.

[0041] ② Prepare 150g / L sodium hydroxide solution with pure water.

[0042] ③ Prepare 2mol / L ammonia water with liquid ammonia.

[0043] Prepare the bottom liquid containing ammonia water, control the pH value at 10.55, the concentration of ammonia water is 7g / L, the temperature is 60°C, the stirring speed is 130r / min, and the metering pumps of ① solution, ② solution, and ③ solution are simultaneously fed, and turned on Solid content regulating valve, when the solid content is controlled at 800g / L, open the overflow discharge valve, pass through the particle size analyzer during the precipitation reaction, and observe the spherical shape with a microscope. The feeding time is 2h, the temperature is 55°C, and the pH is controlled at 11.5. Aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com