Dirty blocking inhibitor and application in water treatment thereof

A technology of scale and corrosion inhibitors and copper corrosion inhibitors, applied in water/sludge/sewage treatment, descaling and water softening, chemical instruments and methods, etc., to achieve excellent scale inhibition performance, inhibit silicon scale and magnesium scale Formation, excellent anti-scaling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

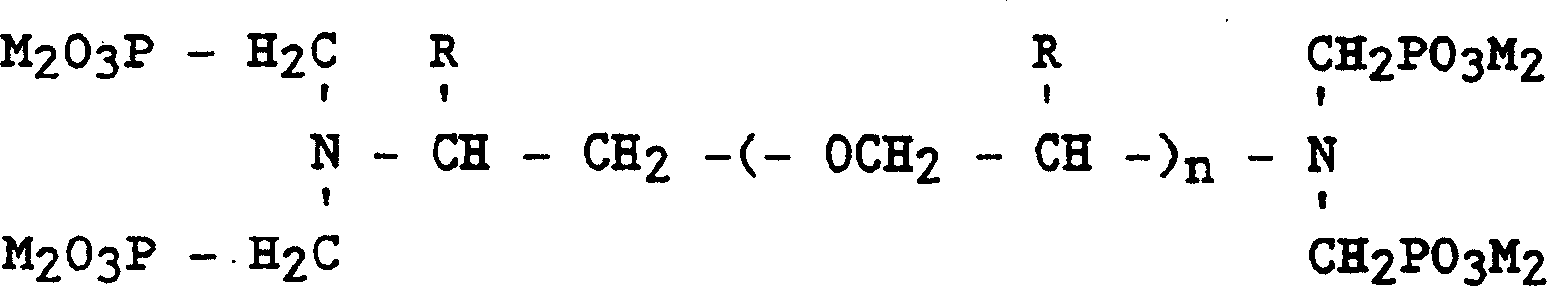

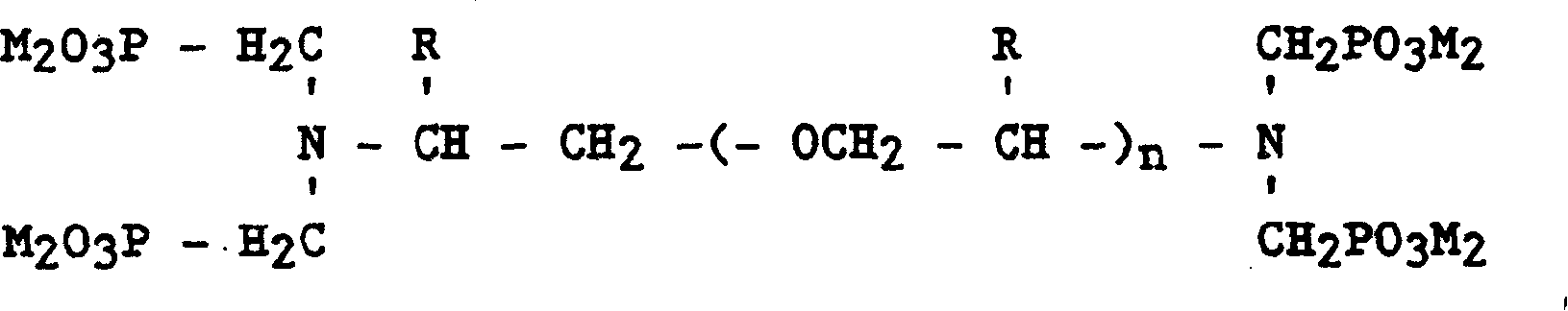

Method used

Image

Examples

Embodiment 1

[0039] Preparation of scale and corrosion inhibitors

[0040] Add 280Kg polyamino polyether base methylene phosphonic acid, 150Kg polyaspartic acid, 150Kg acrylic acid 2-acryloyl-2-methylpropanesulfonic acid / hydroxypropyl acrylate terpolymer, 140Kg di Ethylenetriaminepentamethylenephosphonic acid, 7Kg manganese acetate, stir well, then add 110Kg zinc sulfate and 150Kg concentrated sulfuric acid, stir well, then add 13Kg benzotriazole, stir at a certain temperature for a certain period of time, to obtain 1000Kg medicament.

[0041] The product is a yellow to reddish-brown transparent liquid, specific gravity > 1.20, pH 35%, total phosphorus content 6-10%, orthophosphorus and phosphorous content 1.0%.

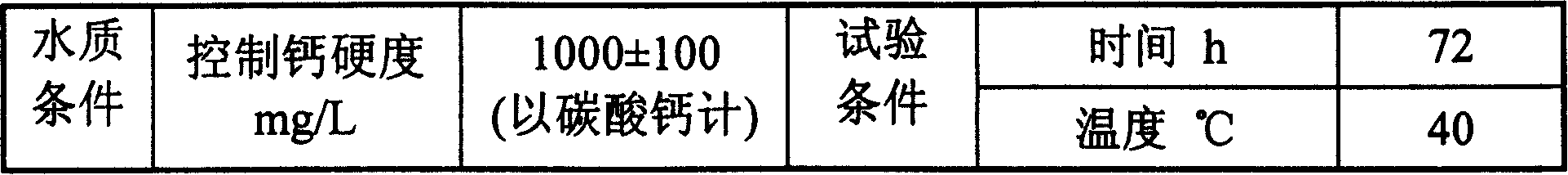

[0042] Determination of scale inhibition performance (static test)

[0043]Under the water quality conditions of calcium hardness 1200mg / L (calculated as calcium carbonate) and total alkalinity of 1200mg / L (calculated as calcium carbonate), scale and corrosion inhibitors we...

Embodiment 2

[0061] Preparation of scale and corrosion inhibitors

[0062] In the reaction flask, add 40g polyamino polyether methylene phosphonic acid, 8g polyaspartic acid, 20g acrylic acid / 2-acryloyl-2-methylpropanesulfonic acid / hydroxypropyl acrylate terpolymer, 10g Diethylenetriaminepentamethylenephosphonic acid, 1g of manganese acetate, 1g of benzotriazole, 10g of zinc sulfate and 10g of concentrated sulfuric acid were stirred evenly at a certain temperature to obtain 100g of the medicament.

[0063] Measurement method of scale inhibition performance (static test), measurement method of corrosion inhibition performance (static test) / water quality conditions / test conditions, measurement method of scale and corrosion inhibition performance (dynamic simulation test) / replenishing water quality of circulating cooling water and examples 1, the other measurement conditions and results are shown in Table 5.

Embodiment 3

[0065] Preparation of scale and corrosion inhibitors

[0066] In the reaction flask, add 30g polyaminopolyether-based methylene phosphonic acid, 20g polyaspartic acid, 10g acrylic acid / 2-acryloyl-2-methylpropanesulfonic acid / hydroxypropyl acrylate terpolymer, 20g Diethylenetriaminepentamethylenephosphonic acid was stirred evenly at a certain temperature, and then 1g of benzotriazole, 1g of manganese acetate, 8g of zinc sulfate and 10g of concentrated sulfuric acid were added in sequence, and stirred evenly to obtain 100g of the medicament.

[0067] Measurement method of scale inhibition performance (static test), measurement method of corrosion inhibition performance (static test) / water quality conditions / test conditions, measurement method of scale and corrosion inhibition performance (dynamic simulation test) / replenishing water quality of circulating cooling water and examples 1, the other measurement conditions and results are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Corrosion rate | aaaaa | aaaaa |

| Corrosion rate | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com