Efficient lithium metal composite material and preparation method thereof, applications of efficient lithium metal composite material as negative electrode

A technology of composite materials and lithium metal, applied in nanotechnology for materials and surface science, negative electrodes, battery electrodes, etc., can solve problems such as the fragility of solid electrolyte membranes, the consumption of active materials in batteries, and low Coulombic efficiency. Good adsorption of molten lithium, inhibition of dendrite growth, and reduction of current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

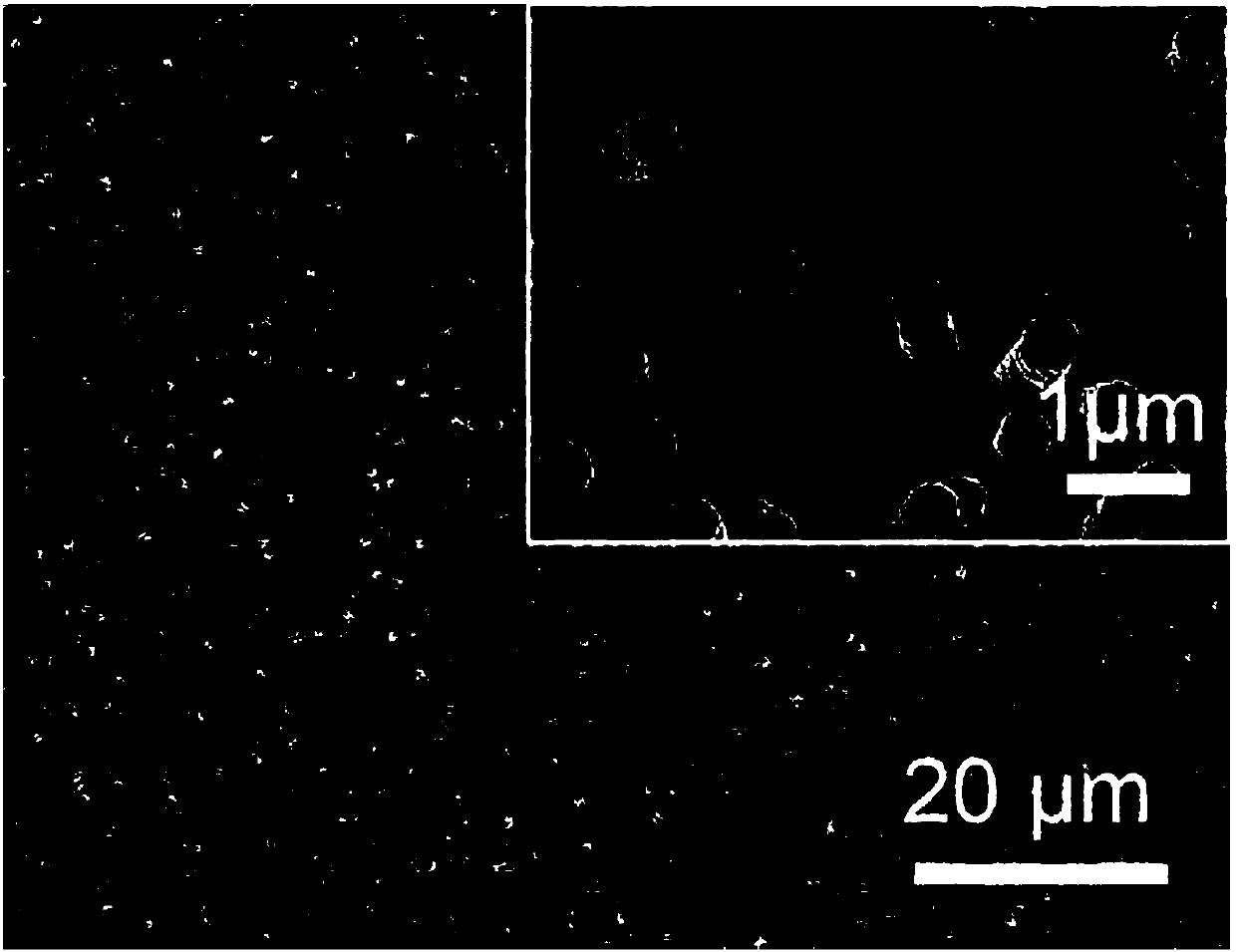

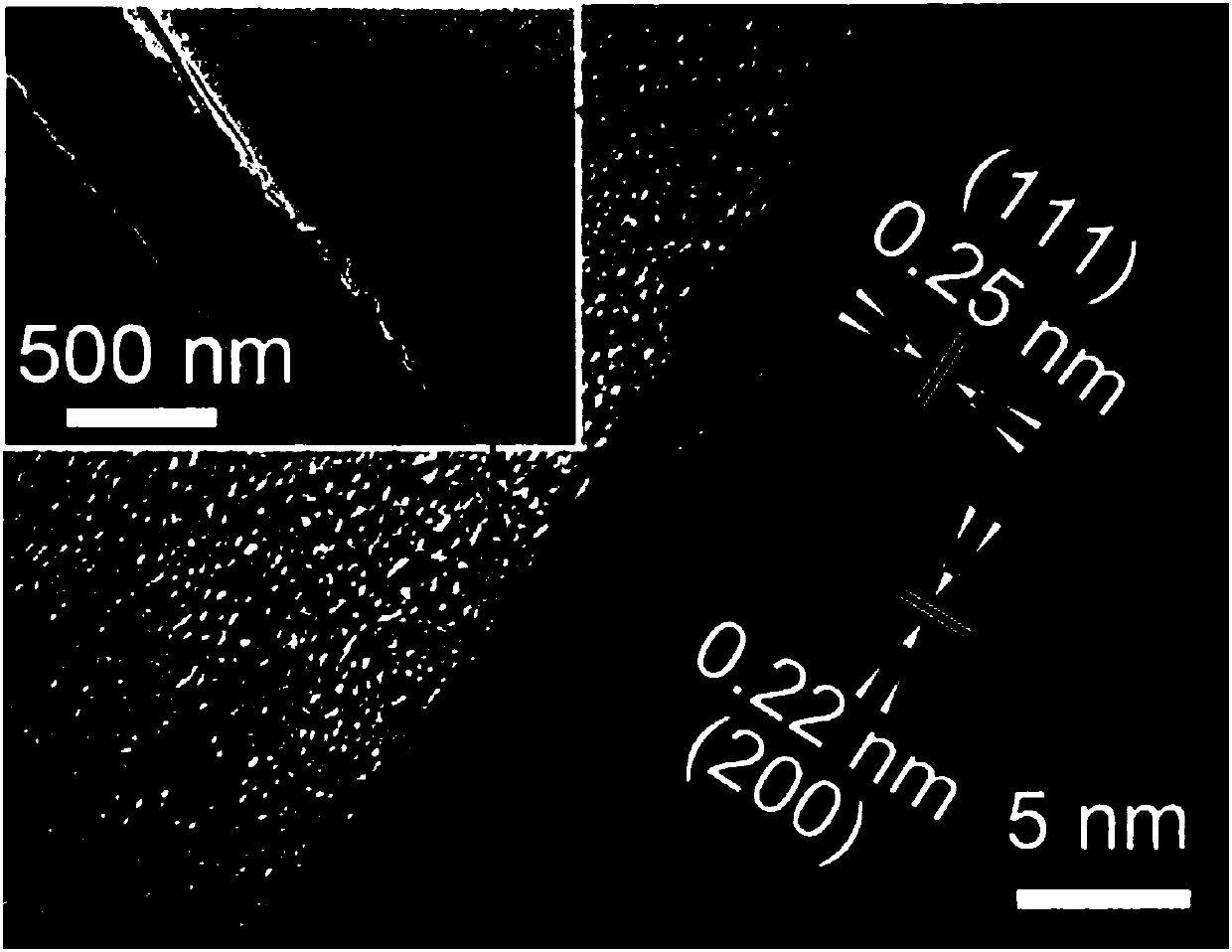

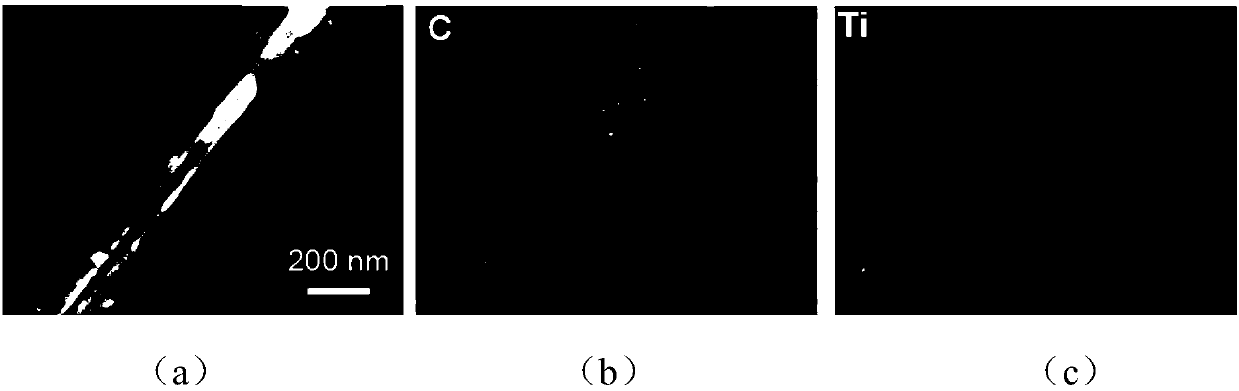

[0035] Ti 6 Al 4 V flakes (0.3 mm) were ultrasonically cleaned in ethanol for 20 minutes, then washed 3 times with deionized water, and dried in a vacuum oven. The cleaned Ti 6 Al 4 The V-sheet is placed in the center of the tube furnace. Before the reaction, the residual oxygen in the tube was removed by pure argon to ensure that the reaction was under an inert atmosphere. After the temperature was raised to 600° C. for 1 hour, acetone gas was introduced into the reaction chamber at a flow rate of 50 sccm by argon bubbling. After reacting at 600°C for 1 hour, it was changed to pure argon and cooled to room temperature 25°C. The nanowire array substrate with TiC / C core-shell structure was prepared. Then solid metal Li (water and oxygen content are both lower than 0.1ppm) was melted in an argon-filled glove box. After the metal Li was completely melted at 300 °C, the prepared TiC / C array substrate was contacted with molten Li. After 20 s, molten liquid Li is adsorbed in t...

Embodiment 2

[0037] Ti 6 Al 4 V flakes (0.3 mm) were ultrasonically cleaned in ethanol for 20 minutes, then washed 3 times with deionized water, and dried in a vacuum oven. The cleaned Ti 6 Al 4The V-sheet is placed in the center of the tube furnace. Before the reaction, the residual oxygen in the tube was removed by pure argon to ensure that the reaction was under an inert atmosphere. After the temperature was raised to 800° C. for 2 hours, acetone gas was introduced into the reaction chamber at a flow rate of 150 sccm by argon bubbling. After reacting at 800°C for 3 hours, it was changed to pure argon and cooled to room temperature 25°C. The nanowire array substrate with TiC / C core-shell structure was prepared. Then solid metal Li (water and oxygen content are both lower than 0.1 ppm) was melted in an argon-filled glove box. After the metal Li was completely melted at 400 °C, the prepared TiC / C array substrate was contacted with molten Li. After 40 s, molten liquid Li is adsorbed i...

Embodiment 3

[0041] Ti 6 al 4 V flakes (0.3 mm) were ultrasonically cleaned in ethanol for 20 minutes, then washed 5 times with deionized water, and dried in a vacuum oven. The cleaned Ti 6 al 4 The V-sheet is placed in the center of the tube furnace. Before the reaction, the residual oxygen in the tube was removed by pure argon to ensure that the reaction was under an inert atmosphere. After the temperature was raised to 1000° C. for 3 hours, acetone gas was introduced into the reaction chamber at a flow rate of 300 sccm by argon bubbling. After reacting at 1000°C for 5 hours, it was changed to pure argon and cooled to room temperature 25°C. The nanowire array substrate with TiC / C core-shell structure was prepared. Then solid metal Li (water and oxygen content are both lower than 0.1 ppm) was melted in an argon-filled glove box. After the metal Li was completely melted at 500 °C, the prepared TiC / C array substrate was contacted with molten Li. After 60 s, molten liquid Li is adsorbe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com