Chlorination-extraction process of gold in arsenic-containing sulphuric acid slag and comprehensive utilization method of gas heat

A technology of sulfuric acid slag and flue gas, which is applied in the direction of improving process efficiency to achieve the effects of no waste water, reduced system energy consumption, and solving pipeline blockage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

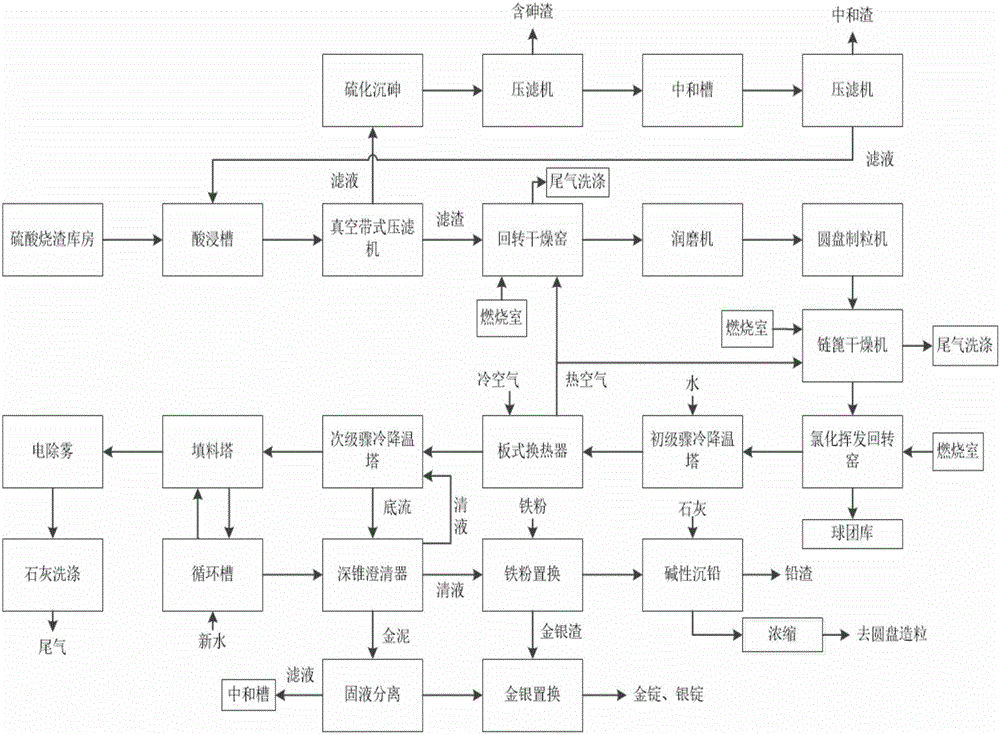

Image

Examples

Embodiment 1

[0039]A process for extracting gold by chlorination of arsenic-containing sulfuric acid slag and a method for comprehensive utilization of flue gas heat, the specific steps are as follows:

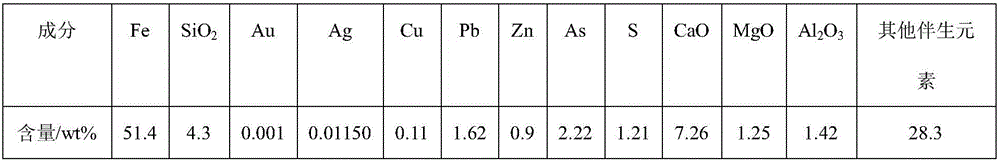

[0040] Composition of sulfuric acid slag before treatment:

[0041] Element

Fe

SiO 2

Au

Ag

Cu

Pb

Zn

As

S

CaO

MgO

al 2 o 3

other accompanying elements

Content / wt%

52

4.2

0.001

0.01143

0.12

1.61

0.9

1.22

1.21

7.26

1.25

1.42

28.8

[0042] Step (1) acid leaching, arsenic sulfide precipitation:

[0043] Sulfuric acid slag 14.6t / h carried out acid leaching, stirring and leaching for 2 hours in an acid leaching tank, and carried out vacuum pressure filtration through a vacuum belt filter press to obtain filtrate A and filter residue A; L of sodium sulfide solution to realize sulfidation and arsenic precipitation, and filter through a filter press to obtain filtrate B and arsenic-c...

Embodiment 2

[0057] A process for extracting gold by chlorination of arsenic-containing sulfuric acid slag and a method for comprehensive utilization of flue gas heat, the specific steps are as follows:

[0058] Composition of sulfuric acid slag before treatment:

[0059] Element

Fe

SiO 2

Au

Ag

Cu

Pb

Zn

As

S

CaO

MgO

Al 2 o 3

other accompanying elements

Content / wt%

52

4.2

0.001

0.01143

0.12

1.61

0.9

1.22

1.21

7.26

1.25

1.42

28.8

[0060] Step (1) acid leaching, arsenic sulfide precipitation:

[0061] Sulfuric acid slag 12t / h is acid leached in an acid leaching tank, stirred and leached for 2 hours, and vacuum-filtered by a vacuum belt filter press to obtain filtrate A and filter residue A; add an appropriate amount of solution to the filtrate A to a concentration of 15g / L Sodium sulfide solution to realize sulfidation and arsenic precipitation, and filter through a filter pr...

Embodiment 3

[0074] A process for extracting gold by chlorination of arsenic-containing sulfuric acid slag and a method for comprehensive utilization of flue gas heat, the specific steps are as follows:

[0075] Composition of sulfuric acid slag before treatment:

[0076] Element

Fe

SiO 2

Au

Ag

Cu

Pb

Zn

As

S

CaO

MgO

Al 2 o 3

other accompanying elements

Content / wt%

52

4.2

0.001

0.01143

0.12

1.61

0.9

1.22

1.21

7.26

1.25

1.42

28.8

[0077] Step (1) acid leaching, arsenic sulfide precipitation:

[0078]Sulfuric acid slag 15.8t / h carried out acid leaching, stirring and leaching for 2 hours in an acid leaching tank, and carried out vacuum pressure filtration through a vacuum belt filter press to obtain filtrate A and filter residue A; L sodium sulfide solution to realize sulfidation and arsenic precipitation, and filter through a filter press to obtain filtrate B and arsenic-cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com