Method and device for producing and synthesizing ethylene glycol by using coal as raw material

A technology for ethylene glycol and raw materials, applied in the field of synthetic ethylene glycol production, can solve the problems of equipment corrosion, low rate of high-quality products, and failure to reach high-quality products, avoiding enrichment, improving the rate of high-quality products, The effect of avoiding corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] For further illustrating the present invention, specifically illustrate in conjunction with following examples:

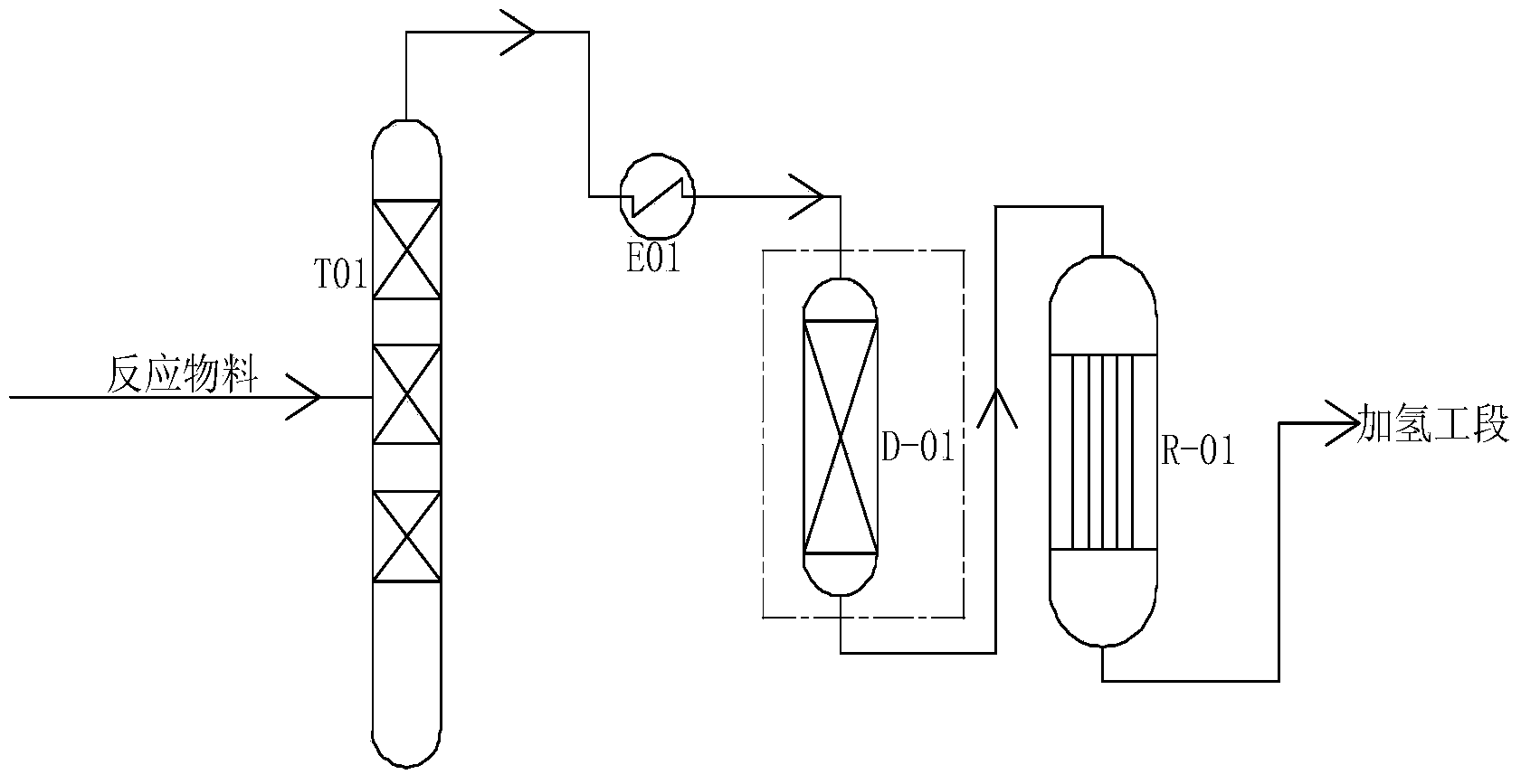

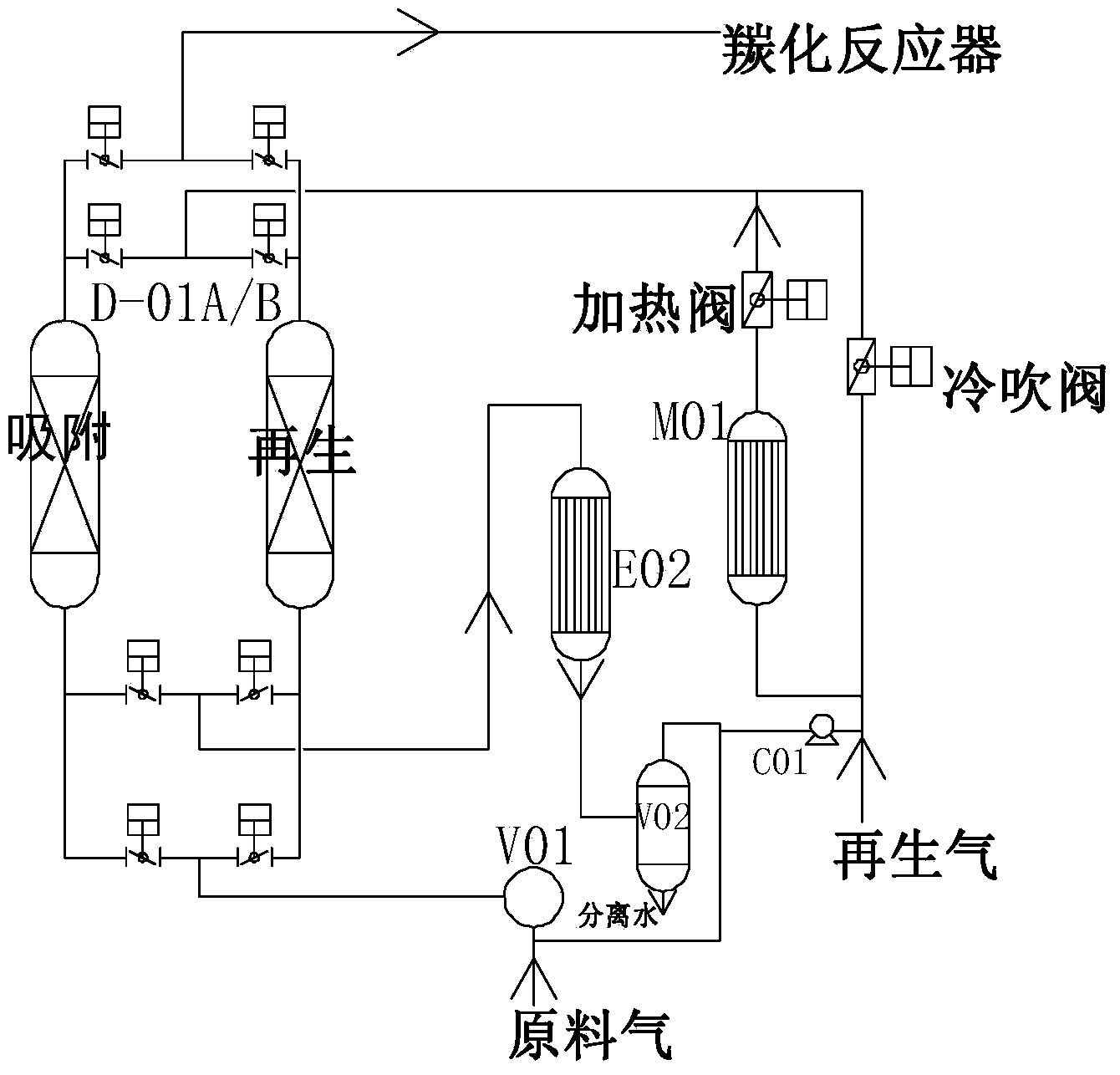

[0014] Such as figure 1 As shown, a method for producing synthetic ethylene glycol with coal as raw material, including oxidative esterification process, carbonylation process and dimethyl oxalate hydrogenation ethylene glycol process, also includes drying and purification equipment, the drying and purification equipment The method is to dry the saturated water in the process gas from the oxidative esterification tower before entering the carbonylation reactor. The working process of the drying and purification equipment specifically includes: the process gas from the top of the oxidation esterification tower T01 is cooled by the cooler E01, and then enters the process gas drying and purification equipment D-01 to absorb saturated water in the process gas, making it enter The moisture contained before carbonylation reactor R-01 is reduced to 10-100ppm.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com