Vacuumizing method for producing large-sized composite material member and composite air extracting layer

A composite material component and vacuum pumping technology, applied in the field of component structure, can solve problems such as rich resin, achieve the effects of reducing consumption, improving utilization rate, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings.

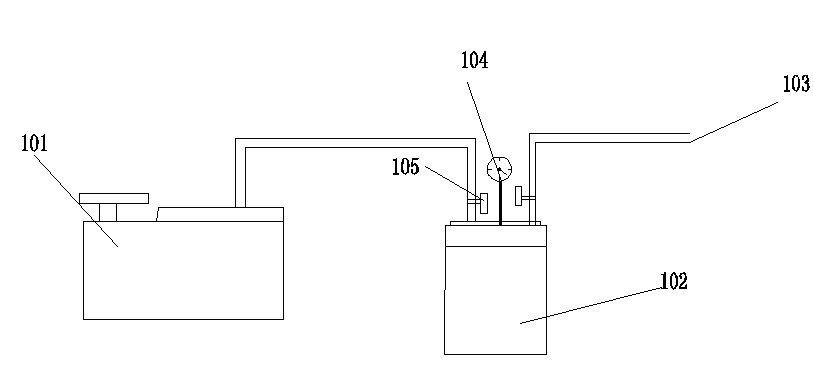

[0021] figure 1 It is the air extraction system of the present invention. The vacuum air extraction device 101 in the pressure regulating pump is connected to the pressure regulating device 102 through a hose, and the pressure regulating device is connected to the mold cavity 106 through the main air extraction pipeline 103 through the air extraction port. When vacuuming, turn on the power supply of the vacuum pumping device 101, and adjust the pressure in the mold cavity by controlling the pressure regulating valve 105 and reading the pressure on the pressure display instrument 104. From the beginning to the mold cavity evacuation, until the end of product curing, the vacuum pumping device 101 will always be in working condition.

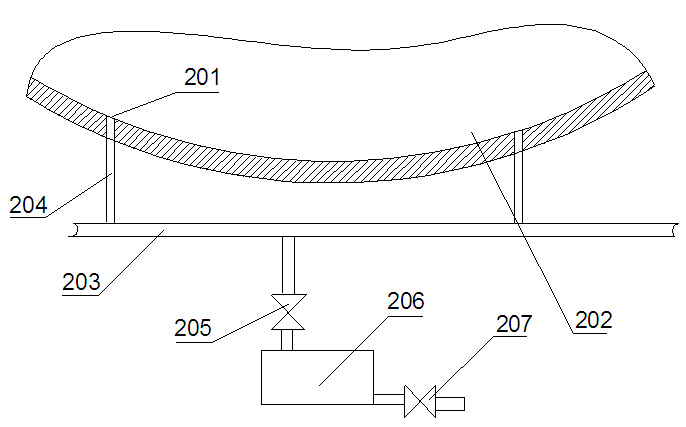

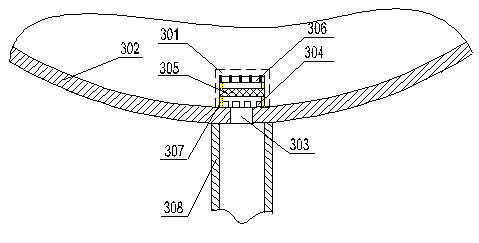

[0022] figure 2 It is a schematic diagram of the pipeline of the vacuum pumping system of the present invention, which describes the sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com