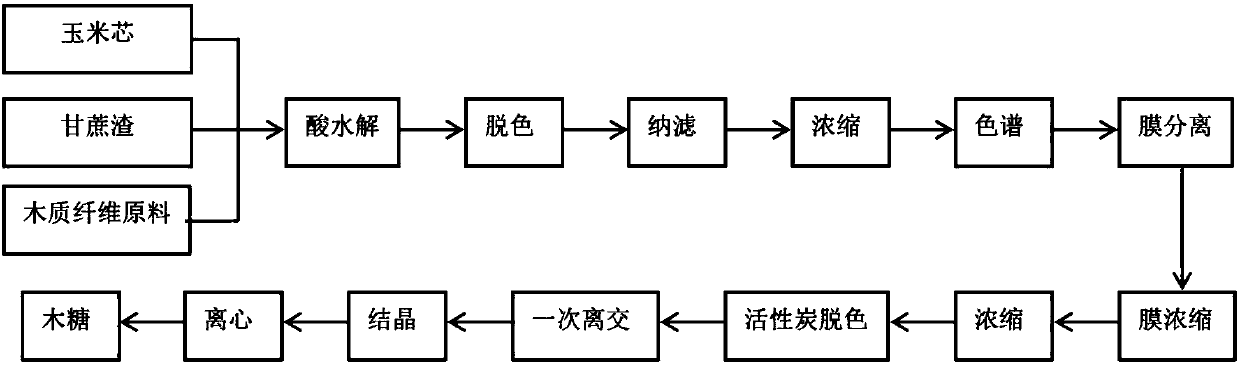

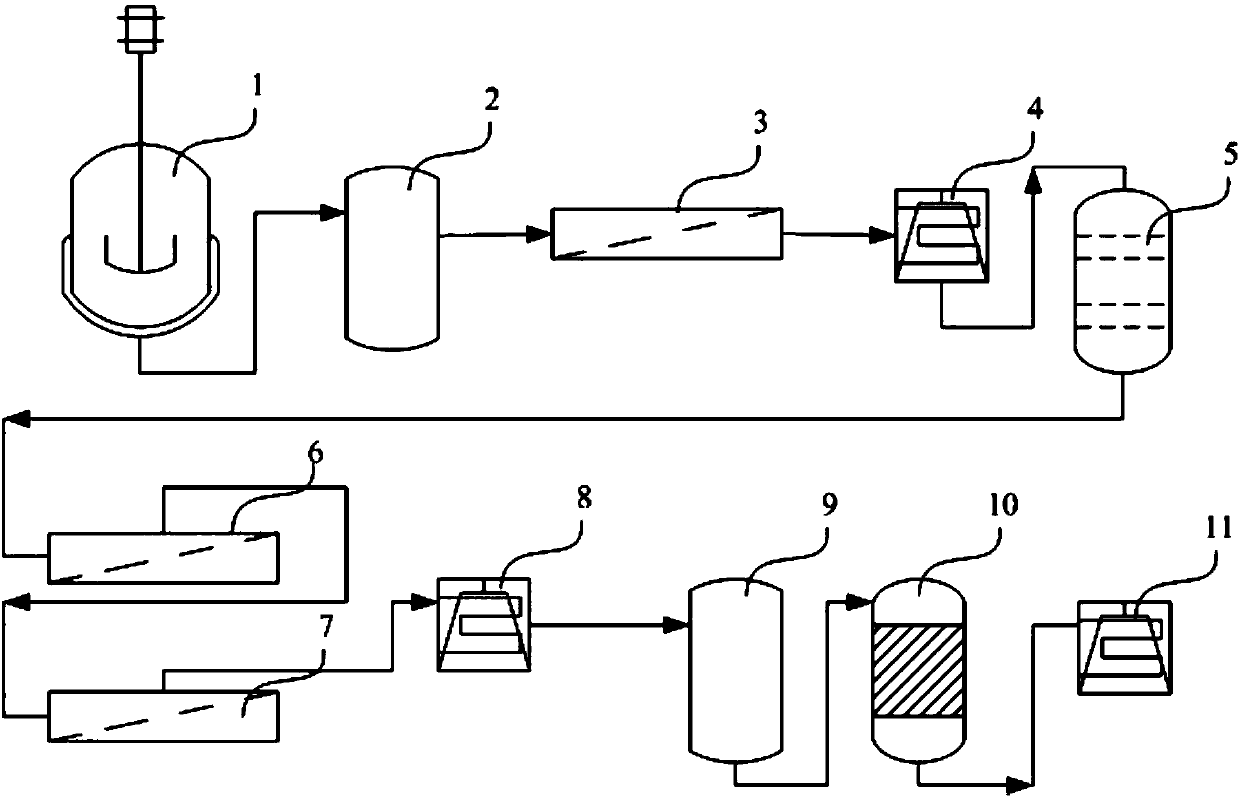

Production method and device for xylose

A production method and technology of a production device, which are applied in the field of functional sugar production, can solve the problems of increasing production costs, easily producing scaling and the like, and achieve the effects of cost saving, green energy-saving manufacturing, and reduced emissions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] Using corncobs as raw materials, add 1.5% hydrochloric acid according to the solid-to-liquid ratio of 1:5 (weight to volume ratio), and keep warm at 125°C for 3 hours. After the reaction, the acid hydrolyzate was obtained by solid-liquid separation, which contained dry matter with a refraction of 7% and a light transmittance of 3%.

[0072] After controlling the temperature of the acid hydrolyzate at 60°C, add 0.5% powdered activated carbon (weight to volume ratio), stir and keep warm for 30 minutes, then plate and frame filter to obtain a decolorizing solution with a light transmittance of 80%.

[0073] The activated carbon decolorization solution enters the nanofiltration membrane recovery system with a molecular weight of 300 Da, an operating pressure of 25 bar, and a temperature of 35°C. The nanofiltration membrane clear liquid is reused for the next acid hydrolysis, and the acid recovery rate is 50%; xylose in the nanofiltration membrane dope solution The refractio...

Embodiment 2

[0080] Using corncobs as raw materials, add 1.2% sulfuric acid according to the solid-to-liquid ratio of 1:5 (weight to volume ratio), and keep warm at 135°C for 2.5h. After the reaction, the acid hydrolyzate was obtained by solid-liquid separation, which contained dry matter with a refraction of 7% and a light transmittance of 2.5%.

[0081] After controlling the temperature of the acid hydrolyzate at 60°C, add 0.8% powdered activated carbon (weight to volume ratio), stir and keep warm for 40 minutes, then plate and frame filter to obtain a decolorizing solution with a light transmittance of 85%.

[0082] The activated carbon decolorization solution enters the nanofiltration membrane recovery system with a molecular weight of 200Da, an operating pressure of 27bar, and a temperature of 40°C. The nanofiltration membrane clear liquid is reused for the next acid hydrolysis, and the acid recovery rate is 55%; the xylose in the nanofiltration membrane dope solution The refraction i...

Embodiment 3

[0089] Bagasse is used as raw material, 1.5% hydrochloric acid is added according to the solid-to-liquid ratio of 1:5 (weight to volume ratio), and the temperature is kept at 135°C for 2.5h. After the reaction is finished, the acid hydrolyzate is obtained by solid-liquid separation, which contains dry matter with a refraction of 6% and a light transmittance of 5%.

[0090] After controlling the temperature of the acid hydrolyzate at 60°C, add 0.6% powdered activated carbon (weight to volume ratio), stir and keep warm for 30 minutes, then plate and frame filter to obtain a decolorizing solution with a light transmittance of 83%.

[0091] The activated carbon decolorization solution enters the nanofiltration membrane recovery system with a molecular weight of 200 Da, an operating pressure of 27 bar, and a temperature of 35°C. The nanofiltration membrane clear liquid is reused for the next acid hydrolysis, and the acid recovery rate is 51%; xylose in the nanofiltration membrane do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refraction | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com