Method for producing molten iron and recovering zinc by utilizing zinc-containing dust or sludge in steelworks

A technology for iron and steel plants and dust sludge, applied in the field of iron and steel smelting waste recycling, can solve the problems of large investment, high energy consumption, poor production stability, etc., and achieve the effects of high energy efficiency, reducing pollution and avoiding enrichment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

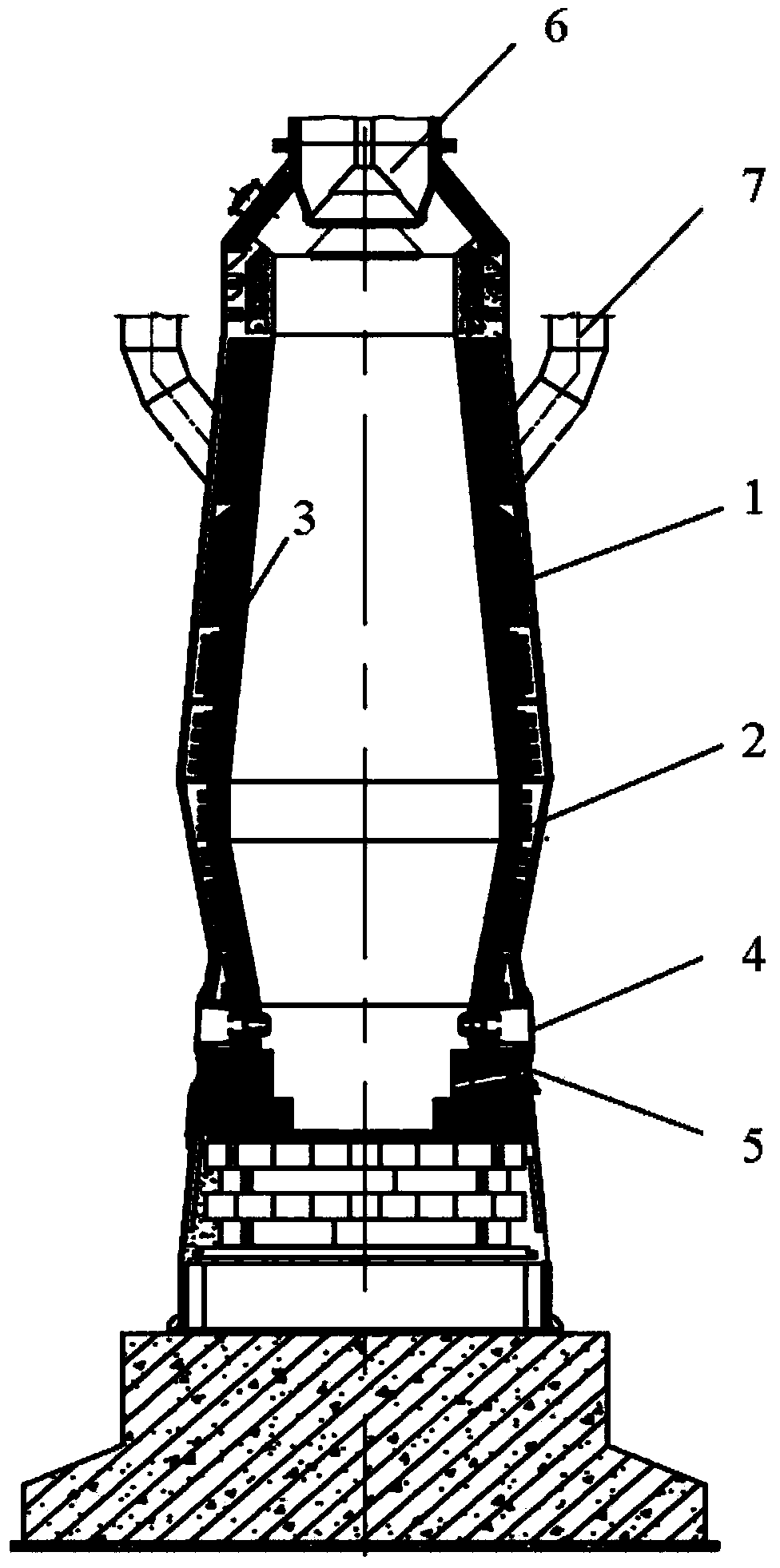

Image

Examples

Embodiment 1

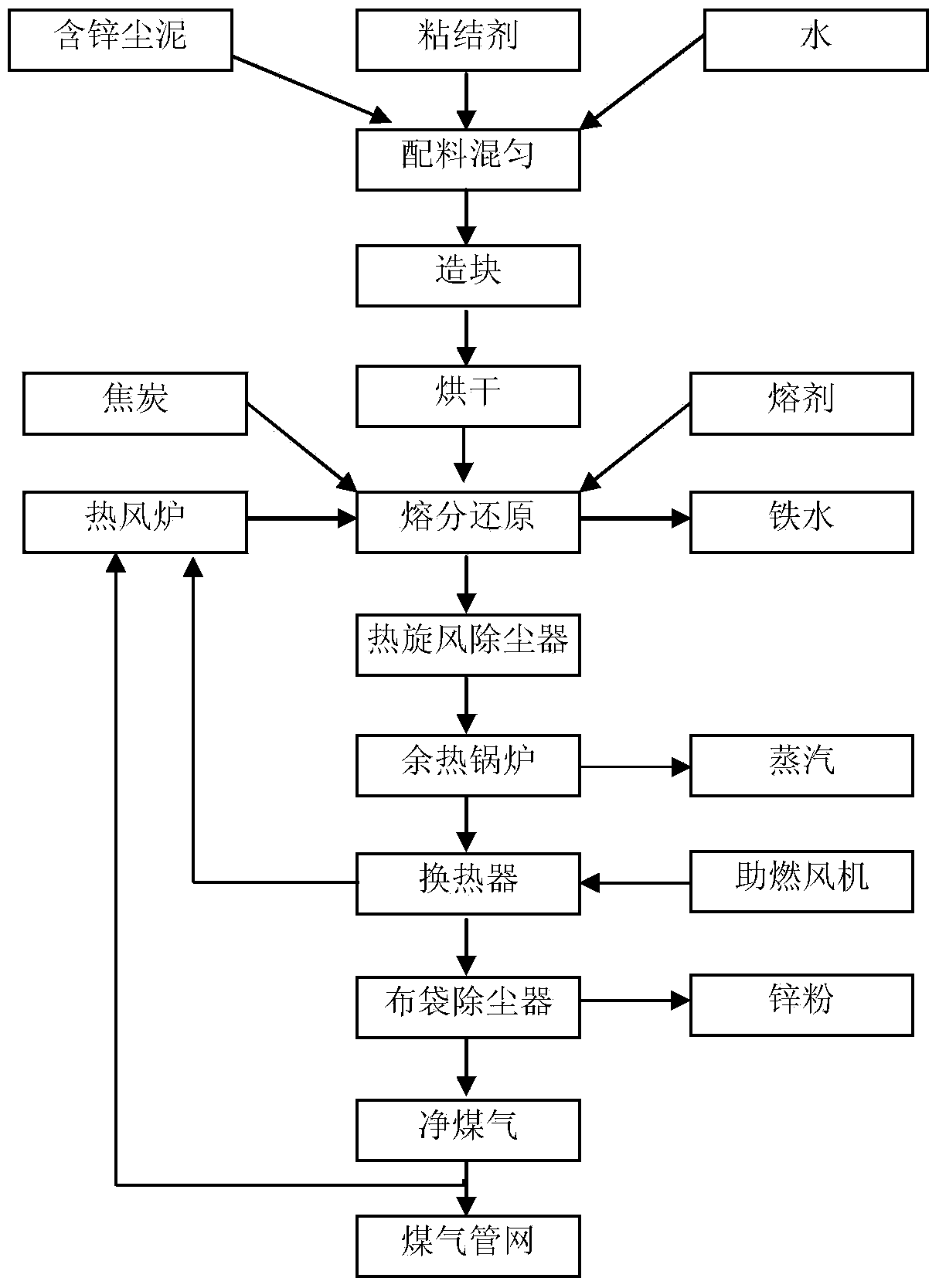

[0040] This embodiment provides a method for producing molten iron and reclaiming zinc by using zinc-containing dust sludge from iron and steel plants. The process flow is as follows figure 2 shown, including the following specific steps:

[0041] 1) Raw material processing and ingredients

[0042] Blast furnace gas ash and converter OG mud stored in the batching bin after drying are batched according to the mass ratio of 1:1. The main components of blast furnace gas ash and converter OG mud are shown in Table 1, and then add a binder, the binder is molasses , the amount of binder used accounts for 5wt% of the mass of zinc-containing dust (the sum of the mass of blast furnace gas ash and converter OG mud), and then adds 5 wt% of the mass of zinc-containing dust (the sum of the mass of blast furnace gas ash and converter OG mud) and) of 2wt% water, mixed uniformly on a mixer to obtain a mixed raw material.

[0043] Table 1 Main components of blast furnace gas ash and convert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com