Crop straw bundle negative-pressure coarse grinding method and crop straw bundle negative-pressure coarse grinding equipment

A technology for crop straw and coarse pulverization, which is applied in the straw energy and straw feed industries, can solve the problems of high sediment content and large straw friction coefficient, and achieve the effect of novel and reliable technology and complete sets of equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

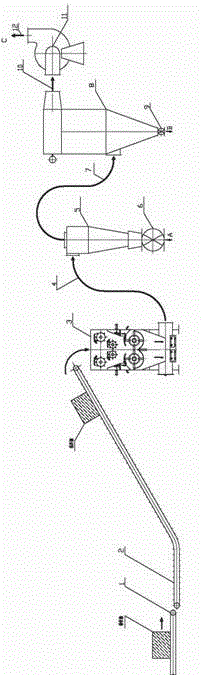

[0019] Such as figure 1 Shown is the flow chart of the negative pressure coarse crushing process of crop straw bales of the present invention.

[0020] ⑴ The process flow is a complete production line ("system" for short), and the process flow is:

[0021] 1. Manual unbundling belt conveyor → 2. Inclined scraper conveyor → 3. Vertical straw bale coarse grinder → 4. Suction pipe → 5. Cyclone separator → 6. Unloading air lock → 7. Suction Air pipe → 8, pulse bag filter → 9, dust collector (connected to 8, pulse bag filter) → 10, suction pipe → 11, high-pressure fan → 12, air outlet pipe.

[0022] (2) In this system, the equipment from the vertical straw bale coarse grinder to the high-pressure fan is connected by a suction pipe, so that the straw bale coarse grinder can work continuously under the state of negative pressure pneumatic conveying, and prevent the straw and dust from flowing outside the process equipment. Ejection, to achieve large-scale clean continuous productio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com