Phosphorus ore dust suppressant composition and preparation method thereof

A technology of dust suppressant and phosphate rock, applied in the direction of chemical instruments and methods, other chemical processes, etc., can solve problems that do not involve dust suppressant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

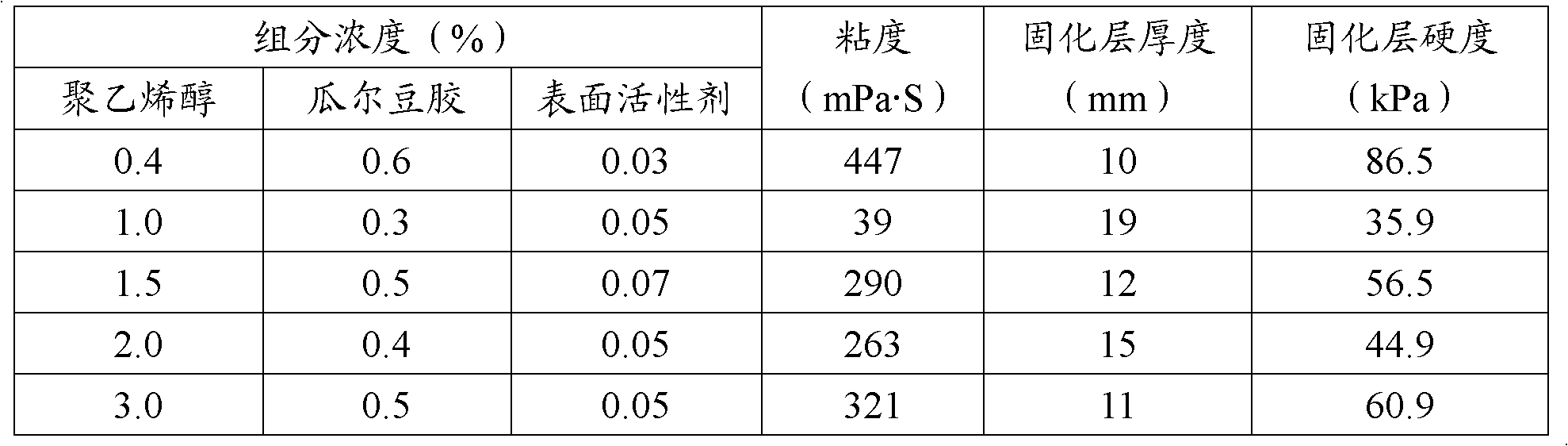

[0092] Example 1 : phosphate rock dust suppressant of the present invention

[0093] The preparation method is as follows:

[0094] A, 0.5 parts by weight of water-soluble polyvinyl alcohol (degree of polymerization 1700, degree of alcoholysis 88) are dissolved in 100 parts by weight of water to obtain a kind of said polyvinyl alcohol solution;

[0095] B, slowly add 1.0 parts by weight of guar gum to the polyvinyl alcohol solution obtained in step A) under stirring, and continue stirring until the guar gum is completely dissolved;

[0096] C, in the solution that step B) obtains, add 0.001 weight part D-581 sterilizer, 1.0 weight part coconut oil fatty acid diethanolamide surfactant again, then stir to obtain uniform solution again;

[0097] D. Allow the solution obtained in step C) to stand for 6 hours, and filter to obtain the phosphate rock dust suppressant.

[0098] The viscosity of the phosphate rock dust suppressant is 263 mPa·S, the thickness of the solidified layer...

Embodiment 2

[0100] Example 2 : phosphate rock dust suppressant of the present invention

[0101] The preparation method is as follows:

[0102] A, 5 parts by weight of water-soluble polyvinyl alcohol (polymerization degree 2400, alcoholysis degree 88) are dissolved with 200 parts by weight of water, obtain a kind of described polyvinyl alcohol solution;

[0103] B, slowly add 0.3 parts by weight of guar gum to the polyvinyl alcohol solution obtained in step A) under stirring, and continue stirring until the guar gum is completely dissolved;

[0104] C, add 0.5 weight part D-581 sterilant, 0.001 weight part sodium dodecylbenzenesulfonate surfactant in the solution that step B) obtains again, then then stir to obtain uniform solution;

[0105] D. Allow the solution obtained in step C) to stand for 7 hours, and filter to obtain the phosphate rock dust suppressant.

[0106] The viscosity of the phosphate rock dust suppressant is 93mPa·S, the thickness of the solidified layer is 17mm and the...

Embodiment 3

[0108] Example 3 : phosphate rock dust suppressant of the present invention

[0109] The preparation method is as follows:

[0110] A, 1.0 parts by weight of water-soluble polyvinyl alcohol (degree of polymerization 2400, degree of alcoholysis 88) are dissolved with 120 parts by weight of water to obtain a kind of said polyvinyl alcohol solution;

[0111] B, slowly add 0.8 parts by weight of guar gum to the polyvinyl alcohol solution obtained in step A) under stirring, and continue stirring until the guar gum is completely dissolved;

[0112] C, in the solution that step B) obtains, add 0.01 weight part D-580 sterilant, 0.8 weight part mink amidopropylamine surfactant again, then stir to obtain uniform solution again;

[0113] D. Allow the solution obtained in step C) to stand for 7 hours, and filter to obtain the phosphate rock dust suppressant.

[0114] The viscosity of the phosphate rock dust suppressant is 183mPa·S, the thickness of the solidified layer is 13mm and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com