Workshop waste gas treatment system

A technology for treating system and workshop waste gas, which is applied in the direction of using liquid separation agent, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of poor waste gas treatment effect and low waste gas treatment volume, and achieve low resistance and high treatment efficiency , the effect of increasing the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

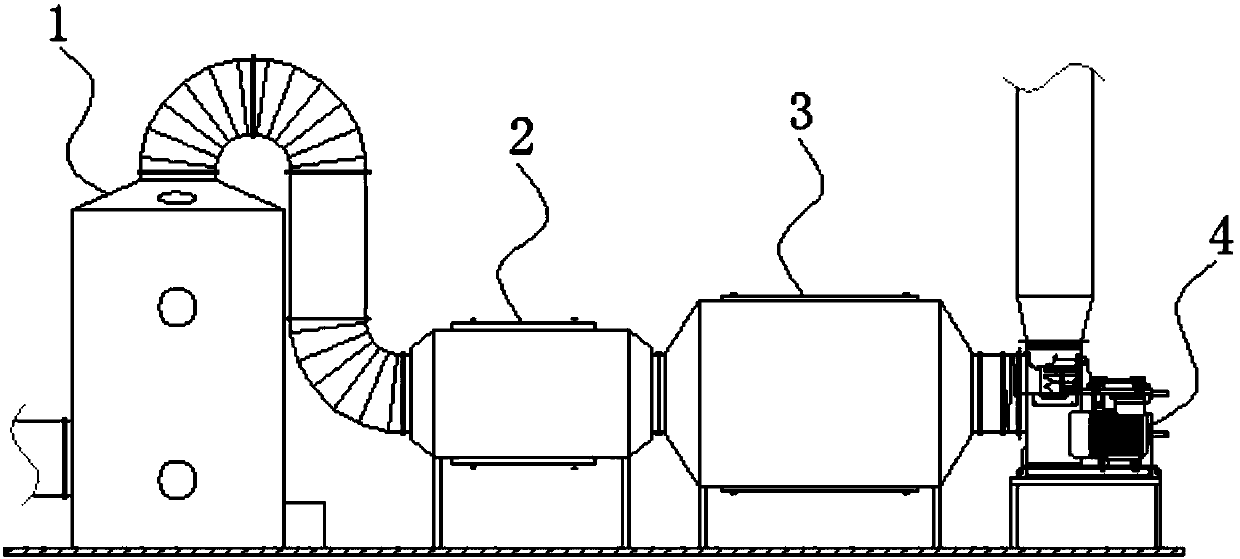

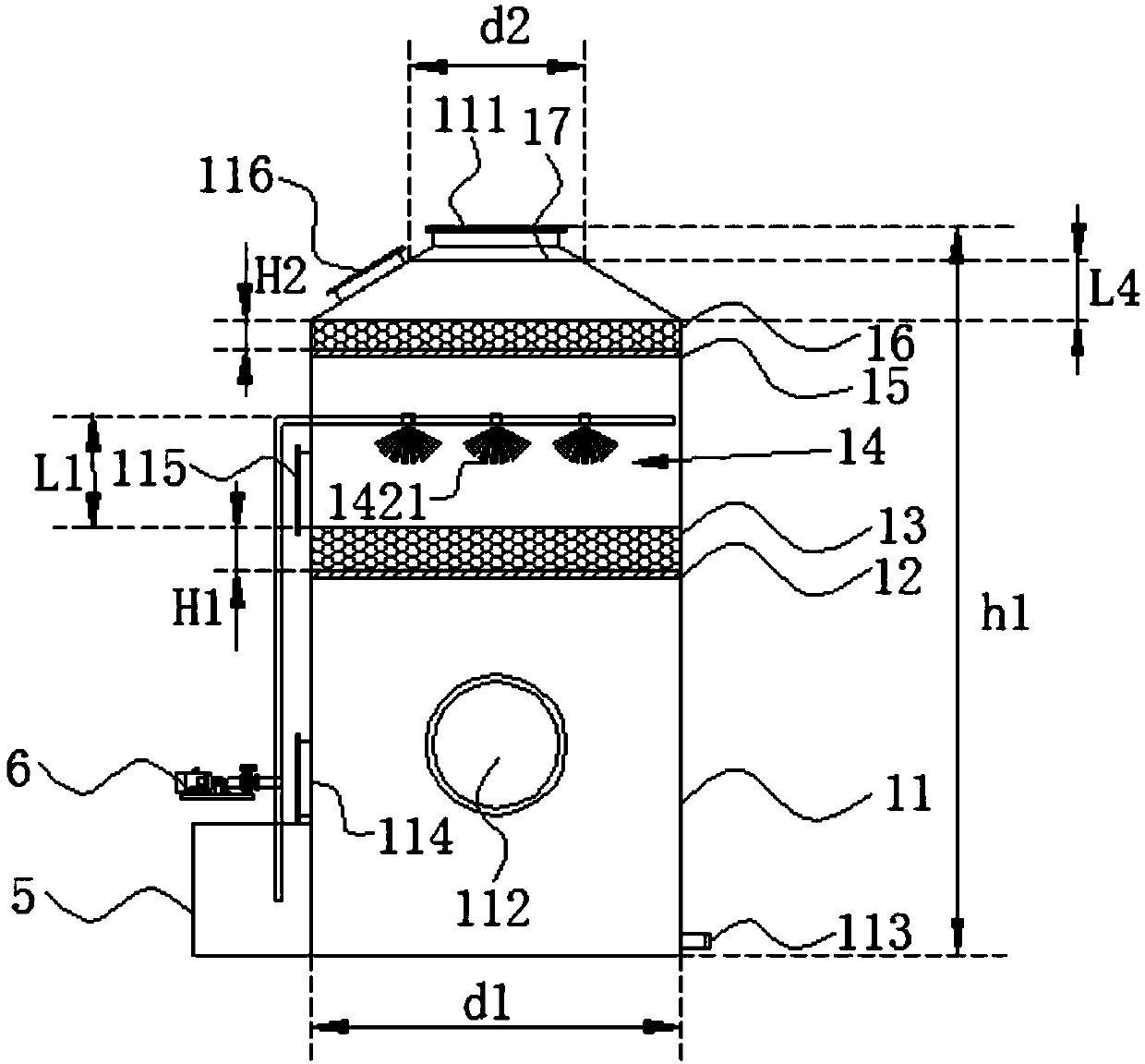

[0061] Embodiment: a kind of workshop exhaust gas treatment system, such as Figure 1-Figure 13 Shown, comprise water washing tower 1, defogging box 2, activated carbon box 3 and blower fan 4, described water washing tower 1 is positioned at the upstream of described defogging box 2, and described defogging box 2 is positioned at the upstream of described activated carbon box 3, The activated carbon box 3 is located upstream of the fan 4;

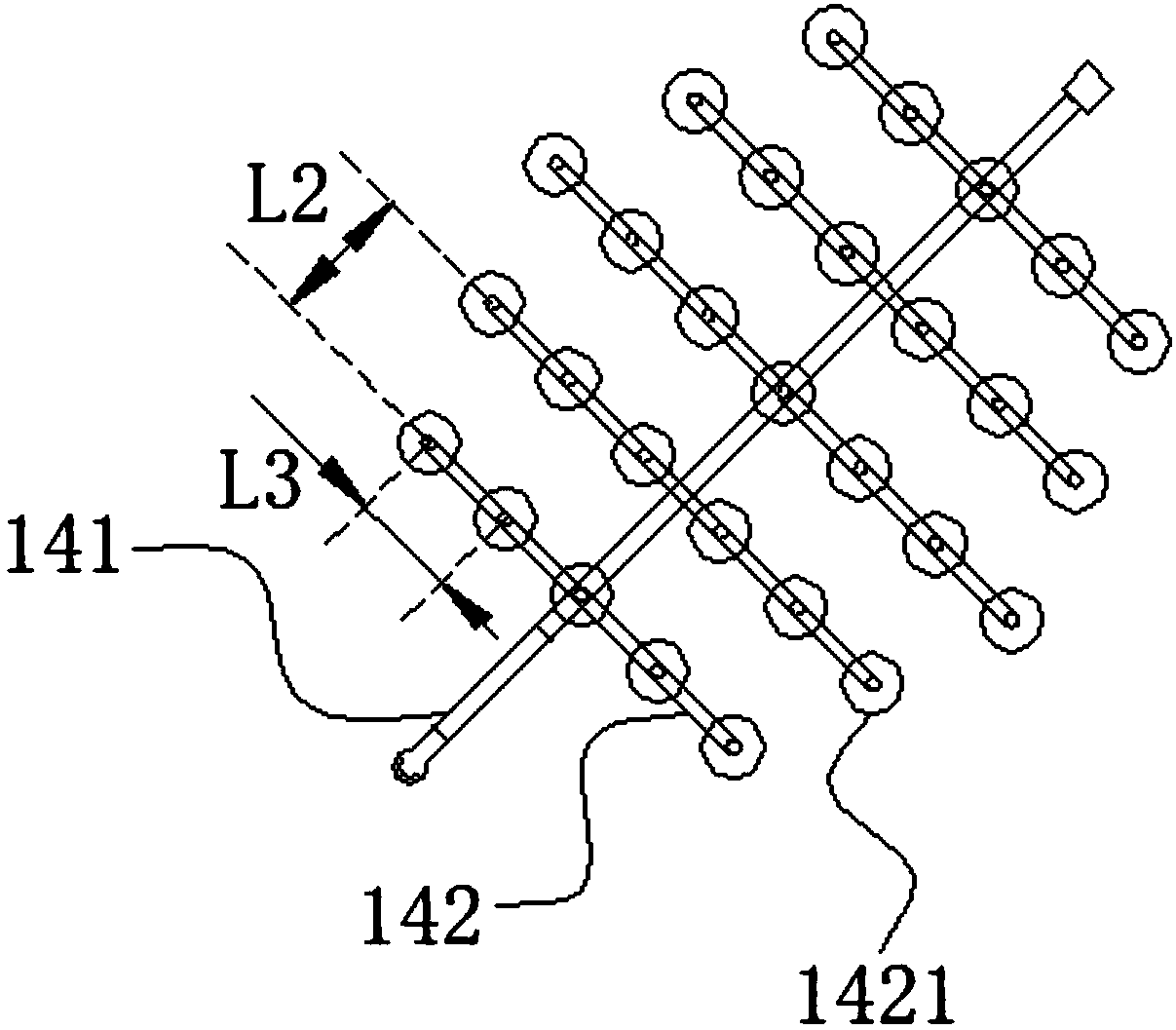

[0062] Described washing tower 1 comprises tower body 11, the first air outlet 111 that is positioned at the upper end of described tower body 11 and the first air inlet 112 that is positioned at the sidewall of described tower body 11 and sewage outlet 113, and described tower body 11 The interior of the tower is sequentially provided with a first packing support frame 12, a gas-liquid mixing layer 13, a spray assembly 14, a second packing support frame 15, a first defogging layer 16, and a top net plate 17 from bottom to top. The side wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com