Mould and method for preparing permeable concrete permeation coefficient measuring sample

A technology of permeable concrete and water permeability coefficient, which is applied in the preparation of test samples, sampling, measuring devices, etc., which can solve the problems of sample preparation, difficult loading of samples, deviation of sample diameter, etc., and achieve simple and efficient preparation process , Disassembly and cleaning are simple, and the effect of shortening the time span

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

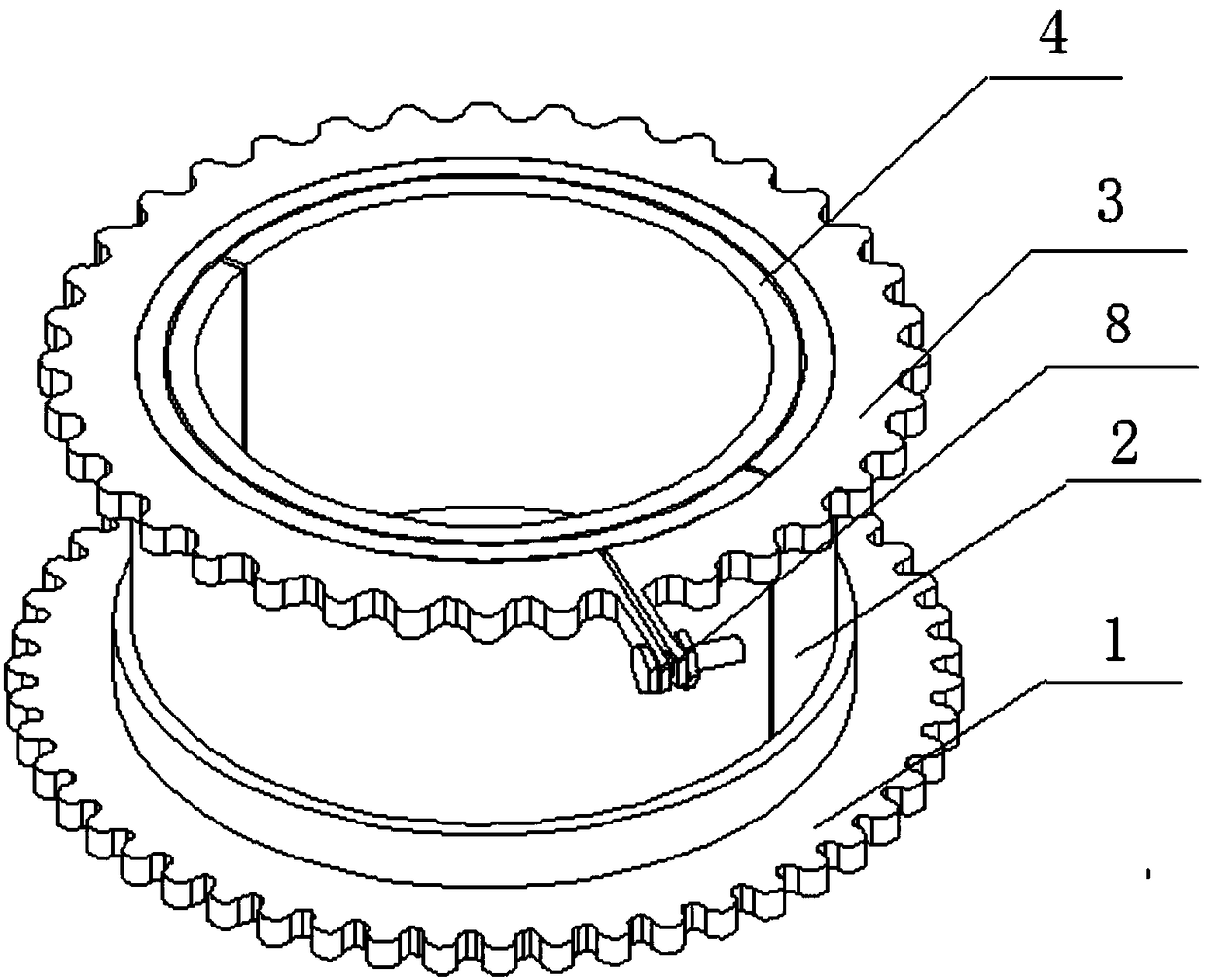

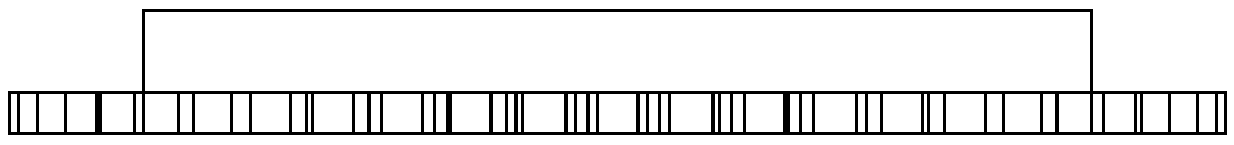

[0040] Such as figure 1 As shown, a single-layer mold used to prepare laboratory permeable concrete water permeability coefficient test samples, including side mold 2, bottom mold 1 and fasteners, the side mold is a ring structure, in the ring structure The side of the side mold is provided with a slit 4 along its axial direction; the inner layer of the side mold is provided with a layer of rubber skin 4, and the side of the rubber skin is also provided with a slit 7 along its axial direction; The side mold is clamped on the bottom mold to close the bottom of the side mold; the fastener is clamped on the outer ring of the side mold to fasten the side mold.

[0041] The effect of setting the slit on the rubber cortex and the side form is mainly for the rubber cortex and the side form to loosen automatically when the form is removed, without using additional devices to disassemble.

[0042] use as Figure 4 The structure of the ring fastener 3 shown is directly slightly larger...

Embodiment 2

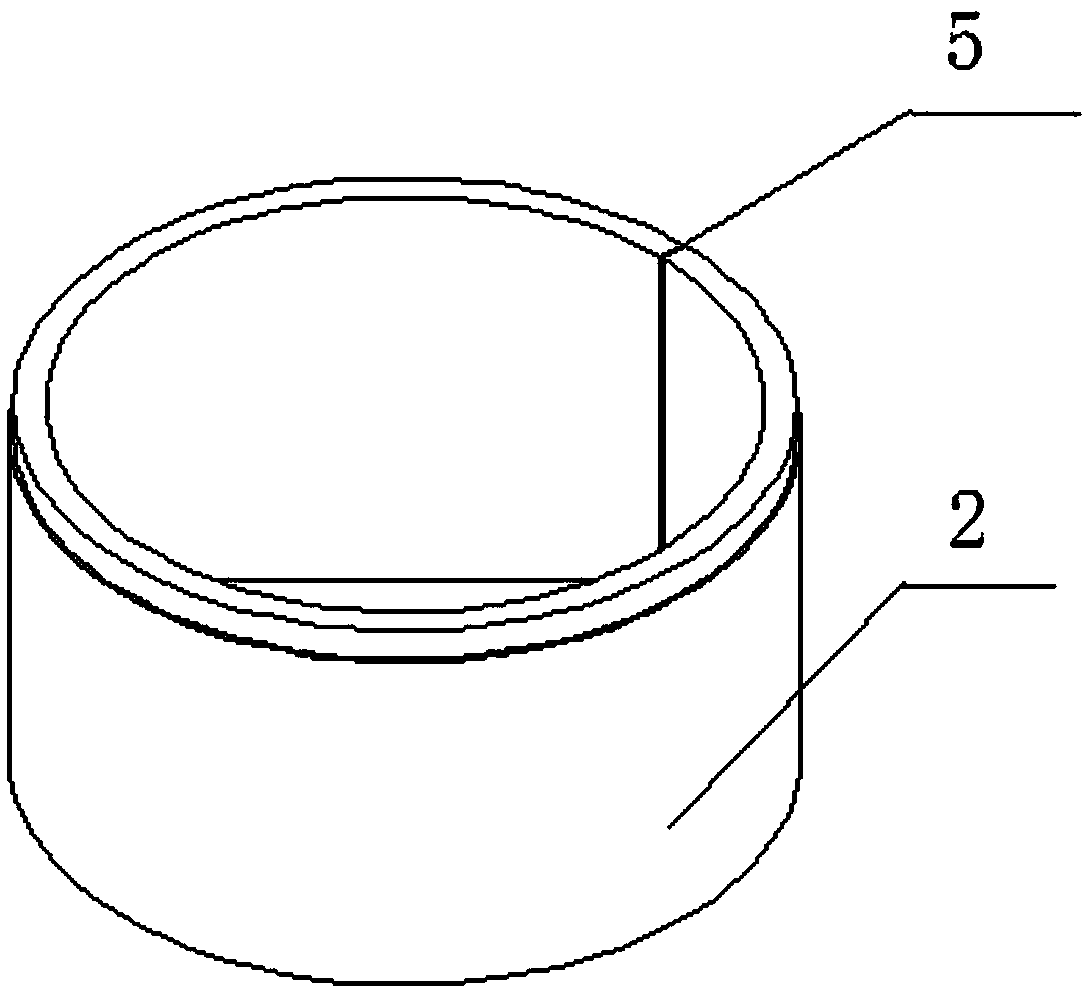

[0053] Such as Figure 6 and Figure 7 As shown, the present invention also provides an embodiment, which is a two-layer mold for preparing a laboratory pervious concrete sample, including two side molds, a bottom mold and two fasteners, and the side mold is a The ring structure has a gap along its axial direction on the side of the ring structure; a layer of rubber skin is arranged on the inner layer of the side mold, and a gap is also provided on the side of the rubber skin along its axis direction; the side The mold is stuck on the bottom mold to close the bottom of the side mold; the fastener is stuck on the outer ring of the side mold to fasten the side mold; the ring fastener fastens the upper part of the lower mold and the side of the upper mold the lower part.

[0054] One of the fasteners is used as Figure 4 The structure of the ring fastener 3 shown, another fastener adopts such as Figure 6 The structure of the ring fastener 6 shown, the difference between the ...

Embodiment 3

[0063] If it is necessary to make a three-layer sample, select the corresponding number of mold layers and combine them according to the actual situation of the tested permeable concrete pavement. The specific method is to remove the ring fastener 3 on the upper end of the test mold of the second layer of permeable concrete water permeability coefficient measurement specimen, and then install a side of the mold, and connect the second layer and the third layer by the ring fastener 6. The side of the mold is fastened, (1 side of the mold is 1 layer, and 1 ring fastener is required; 2 sides of the mold are 2 layers, and 2 ring fasteners are required; 3 sides of the mold are 3 layers, and 3 ring fasteners are required ;). Then put the third layer of rubber leather into a ring shape, put the rubber leather close to the side (3 mold sides are 3 layers, choose 3 rubber leather, total width 150mm), and then, the third layer of side mold The top is fastened by a ring fastener 3; a la...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wear resistance | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com