Flue gas latent energy recovery method in glass smelting kiln

A technology of glass melting furnace and recycling method, which is applied in glass production, glass furnace equipment, glass manufacturing equipment, etc., can solve the problems of easy pollution of batch materials and low comprehensive utilization rate, shorten the time span, reduce smoke and dust emissions, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

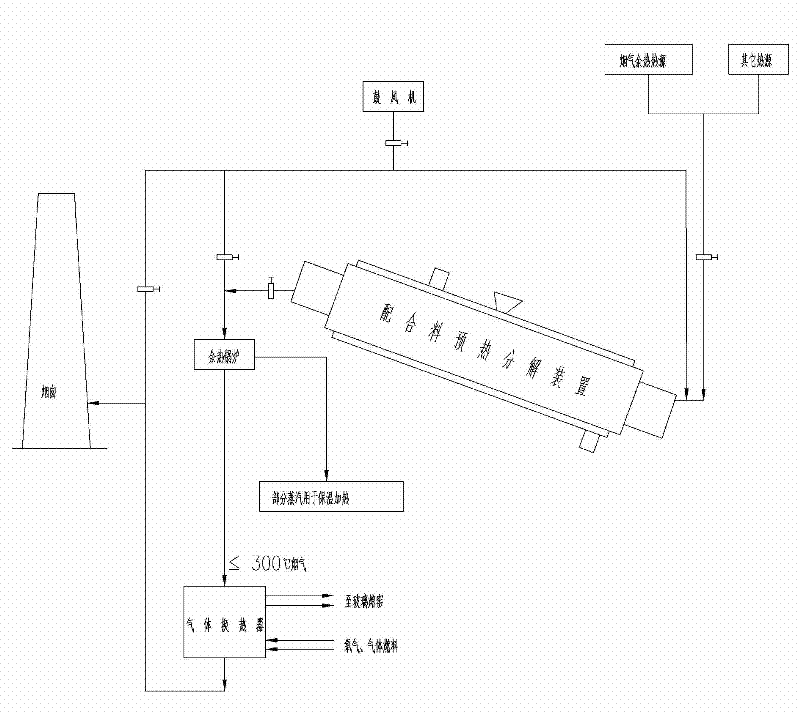

[0058] Such as figure 1 As shown, the system composition adopted in a kind of glass melting kiln flue gas potential recovery method provided by the present invention is as follows:

[0059] The high-temperature flue gas and other heat sources of the glass melting furnace are introduced into the inlet end of the batch material preheating decomposition device through the pipeline, the outlet end of the batch material preheating decomposition device is connected to the waste heat boiler through the pipeline, and the outlet end of the waste heat boiler is connected to the gas heat exchanger through the pipeline. The outlet end of the gas heat exchanger is connected to the chimney through a pipe.

[0060] In addition, a blower is provided to guide the low-temperature air to the inlet and outlet of the preheating and decomposing device for the batch material through the pipeline, so as to adjust the temperature entering the preheating and decomposing device for the batch material. ...

Embodiment 2

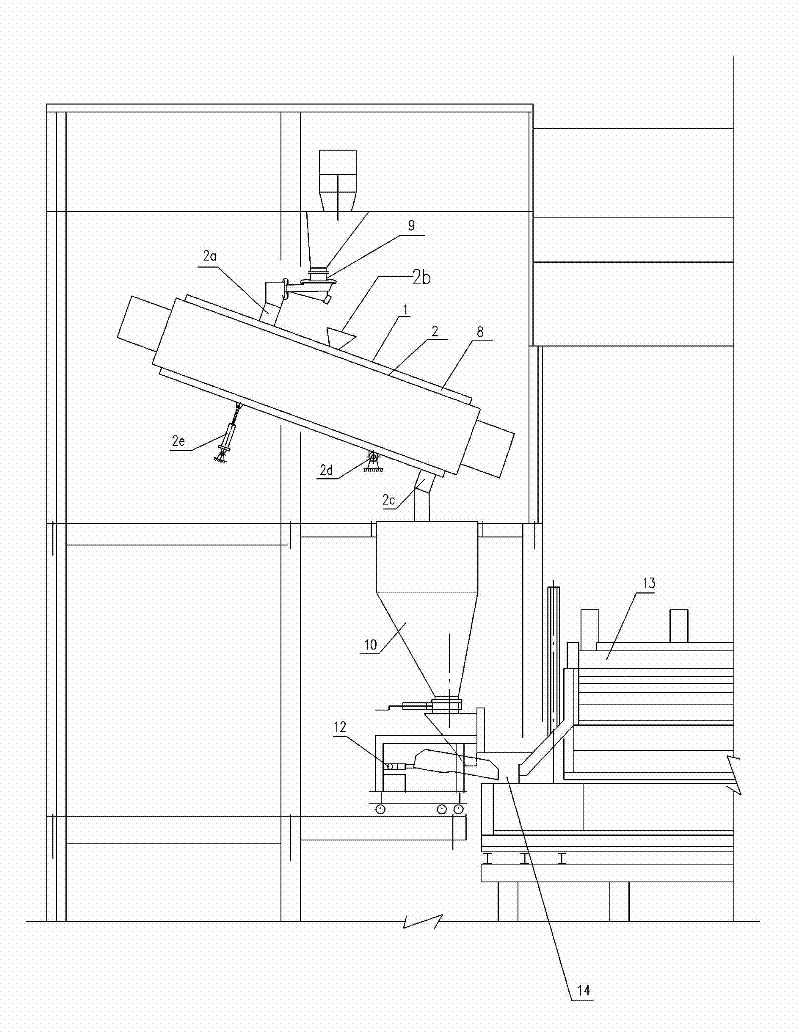

[0067] Such as figure 2 As shown, it is a batch material preheating and decomposition device provided by the present invention—a grid type heat pipe fluidized bed and a structural diagram of a melting furnace system, which includes a batch material vibrating feeder 1 above the melting furnace frame, a melting furnace frame below The thermal insulation feeder 3 and the sealing feeder 4, the sealing feeder 4 will batch the material into the feeding port 5 of the melting furnace 6, and these all belong to the prior art.

[0068] A group of grid-shaped heat pipe fluidized beds 2 are set in the furnace frame, and the upper and lower parts of each decomposition fluidized bed 2 outside the kiln are respectively provided with a feed port 2a, an exhaust port 2b and a discharge port 2c, which are respectively connected with the vibrating feeder 1 cooperates with sealing feeder 4. The lower part of the grid-shaped heat pipe fluidized bed 2 is provided with a hinge shaft 2d to cooperate...

Embodiment 3

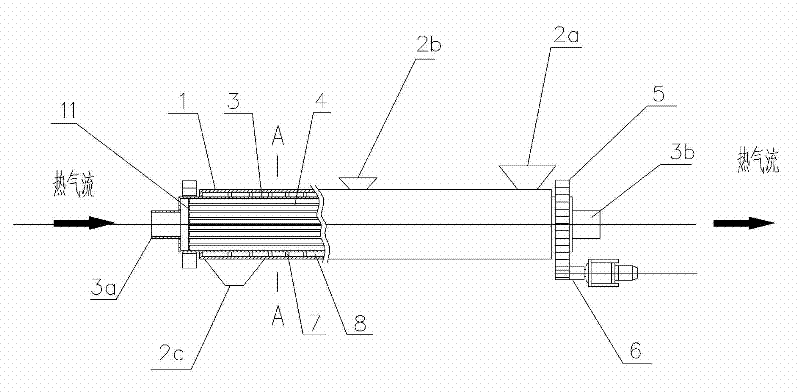

[0072] Such as Figure 6 Shown is another kind of batch material preheating decomposition device provided by the present invention—the structural schematic diagram of the heat pipe fluidized bed device, which includes the following two parts:

[0073] a. A heat pipe heat exchanger, which includes an outer thermal insulation shell 100, a group of high-temperature heat pipes 200 are arranged in the shell, and a partition plate 300 is set in the shell to separate the inner cavity of the shell into a heat collecting area 100a and a heat releasing area 100b . A blower 400 is arranged outside the housing, which is connected to one side of the heat release area 100b through an air inlet pipe 600a, and the other side of the heat release area is connected to an air outlet pipe 600b. As shown in the figure, valves are provided in the air inlet pipe 600a and the air outlet pipe 600b. The high-temperature flue gas inlet pipe 500a is connected to one side of the heat collection area 100a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com