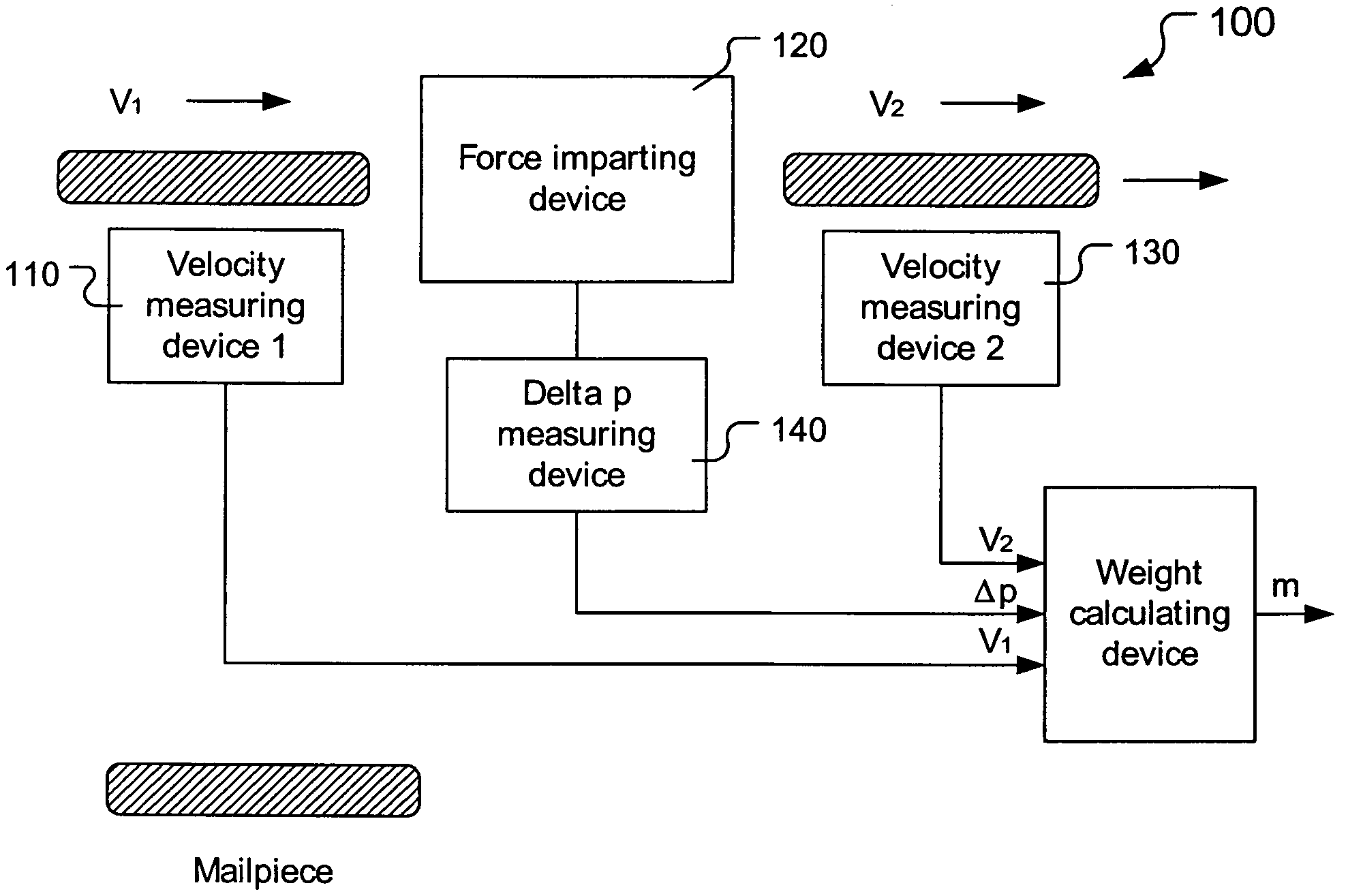

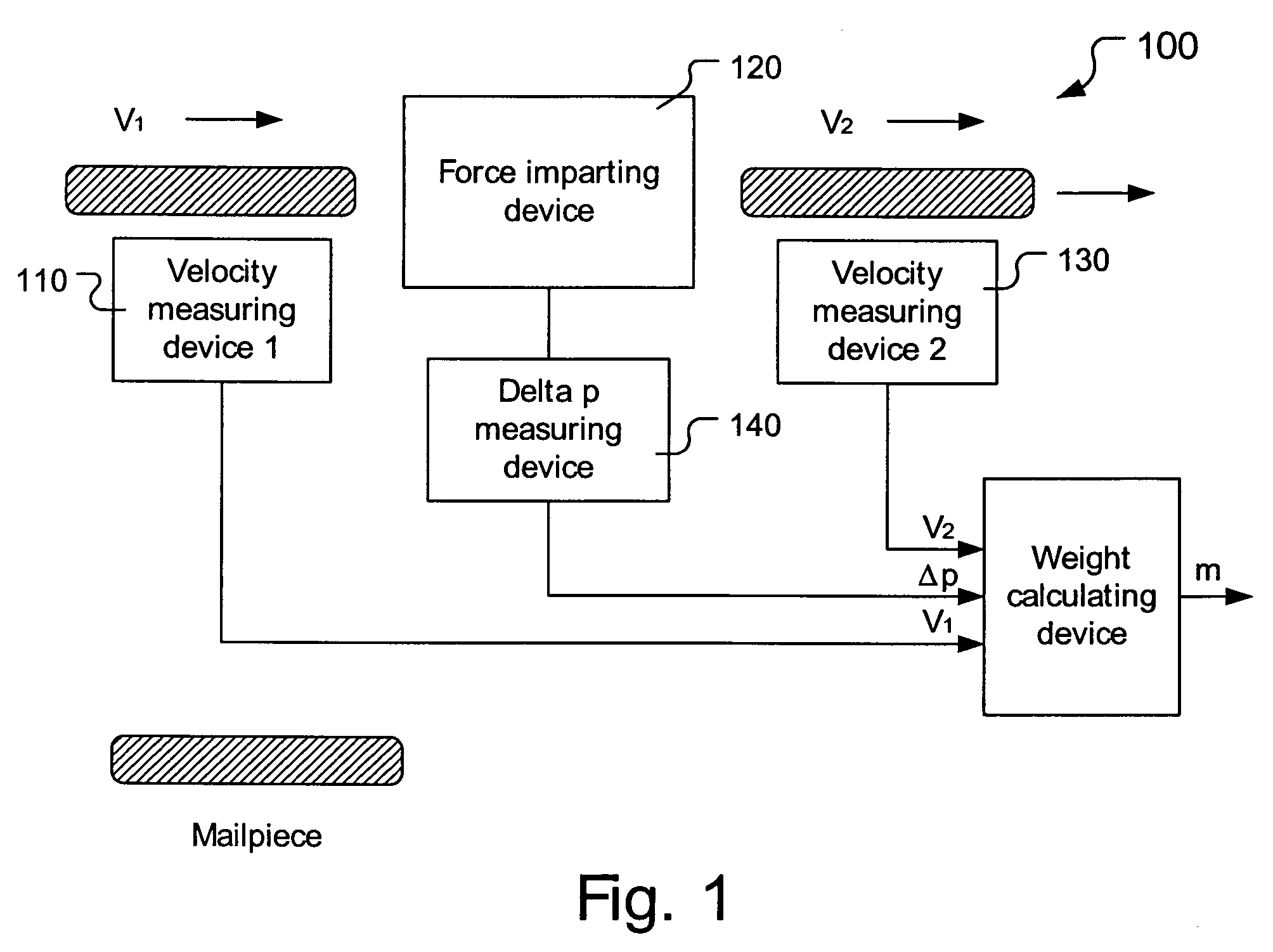

Method and apparatus for determining weight of moving mailpieces

a technology of moving objects and weights, applied in the field of mailpiece processing, can solve the problems of limiting the speed of a mail processing system, consuming a huge amount of human and financial resources, and the mechanical scale for weighting moving objects is highly susceptible to vibration effects,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

second embodiment

of the Invention

[0045]The second embodiment of the invention is shown in FIG. 3. The force imparting device 120 comprises a barrier object such as a lever 320 that is pivotally fastened at one end and is angualarly displaceable by the impact of the mailpiece at the another end. The mailpiece is traveling at a predetermined velocity V1.on a transport means 360 when entering the force imparting device 120. The mailpiece transfers some of its kinetic energy to the lever 320 upon the impact, and the lever is displaced by an angle Δθ before returning to its original position. The displacement angle Δθ is measurable by the measuring means 140.

[0046]The displacement angle Δθ is proportional to inertial mass m of the mailpiece and one can apply equation (7) and using a calibration curve of known masses to derive the mass.

[0047]Preferably, the lever comprises an elongated portion and a wide flat plate mounted at the end of the elongated portion. This is to spread the impact footprint such th...

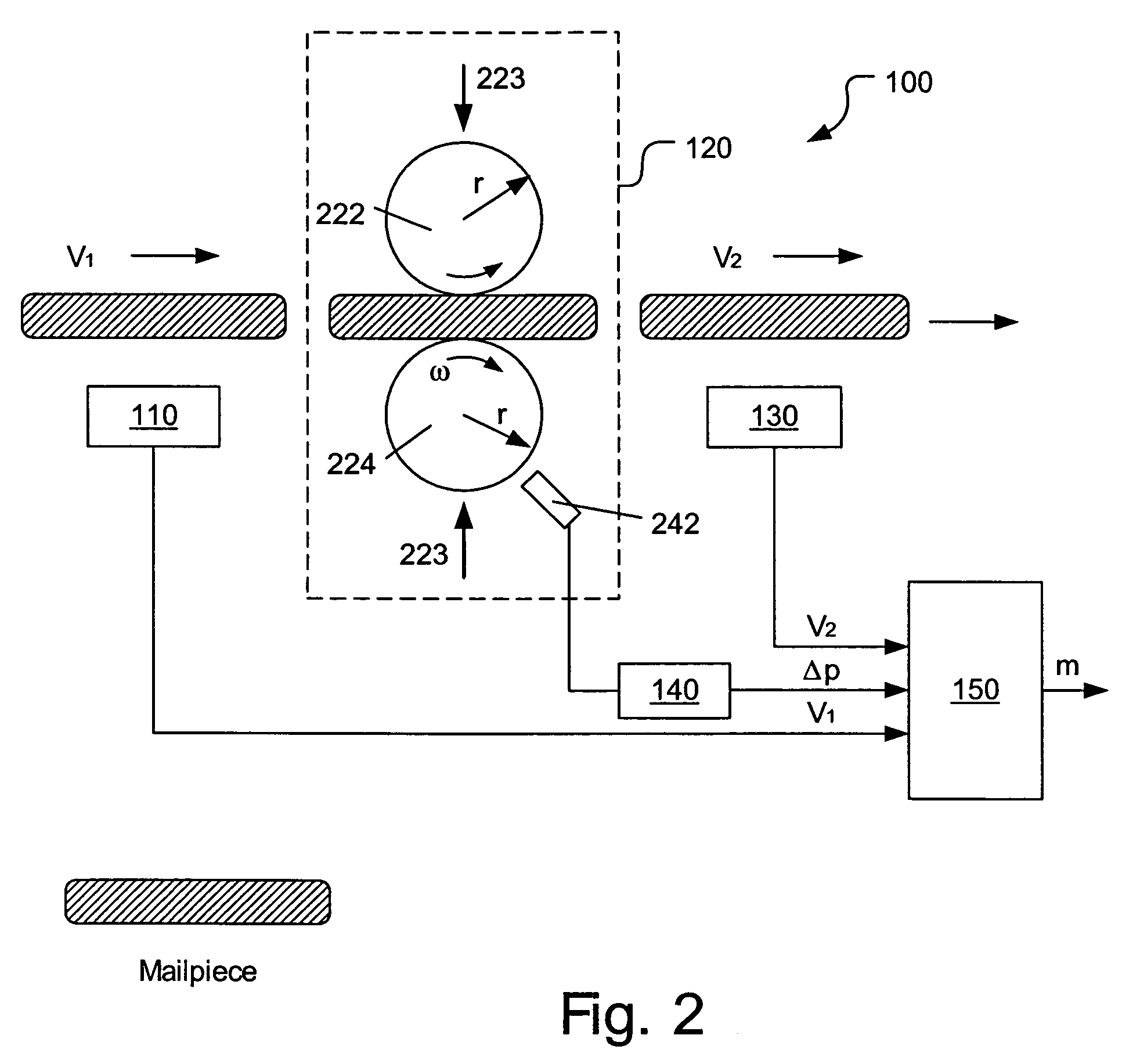

first embodiment

Modification to the Invention

[0052]The first embodiment shown in FIG. 2 can be modified as shown in FIG. 7. In FIG. 7, the force imparting device 120 comprises a first roller 224, a second roller 222 and a calibrated dual-mode servomotor 226 that is coupled with the first roller 224. The first roller 224 and the second roller 222 have substantially the same dimensions and characteristics. The rollers are preferably urged toward each other so as to automatically accommodate mailpieces of different thickness. Whenever there is no mailpiece present in the gap, the first roller 224 is rotating at a constant angular velocity, powered by the servomotor 226. The servomotor 226 is capable of producing a voltage or current signal to a voltage (or current)-to-frequency converter 228 that is in communication with the Δp measuring device 140. Also, the servomotor 226 is in communication with a photocell trigger 230.

[0053]A mailpiece having a first velocity V1 is pinched between the two rollers ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com