Automatic feeding and discharging machine for soft pack lithium batteries

A technology of automatic loading and unloading and soft-pack lithium batteries, which is applied in the direction of conveyors, conveyor objects, mechanical conveyors, etc., can solve the problems of heavy workload, low production efficiency, and large size of power soft-pack batteries to ensure consistency Sexuality, reducing manual operations, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Further illustrate the present invention below in conjunction with accompanying drawing

[0043] Referring to the attached picture:

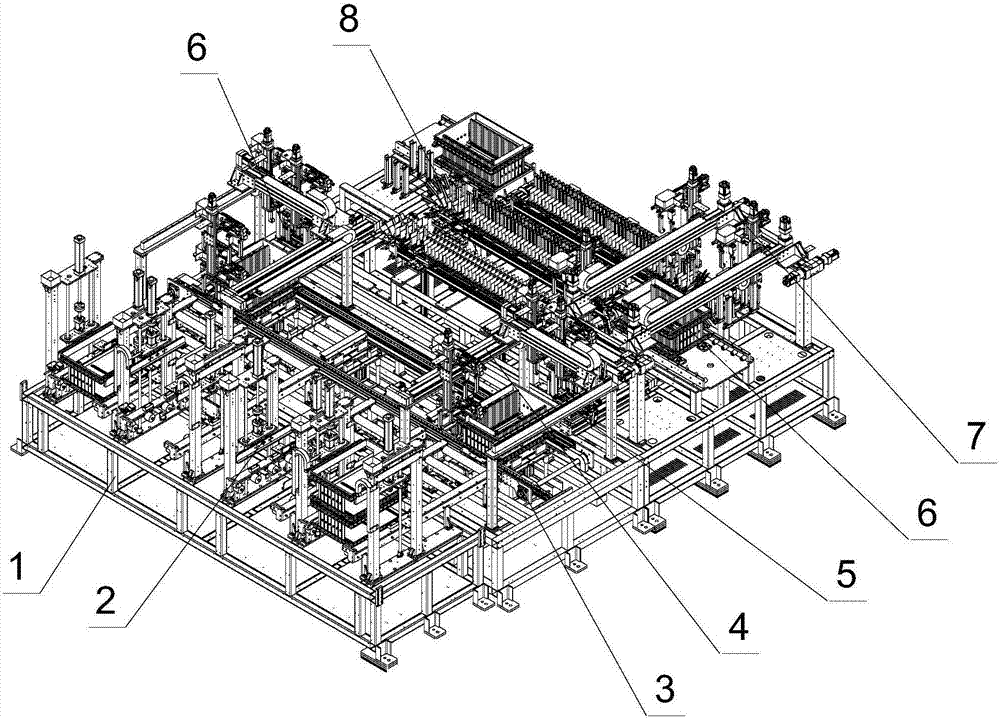

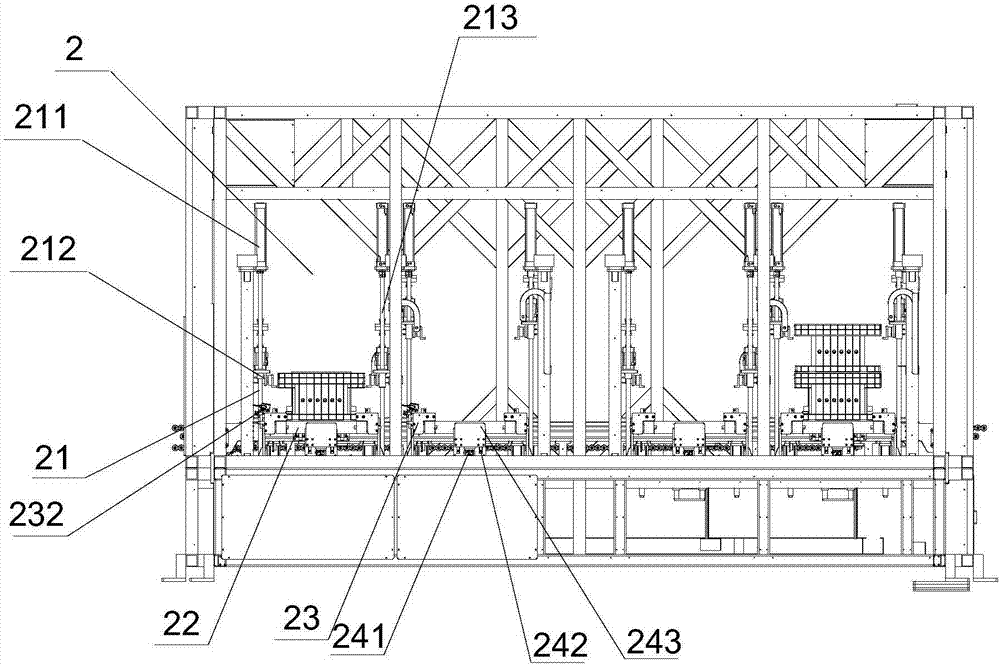

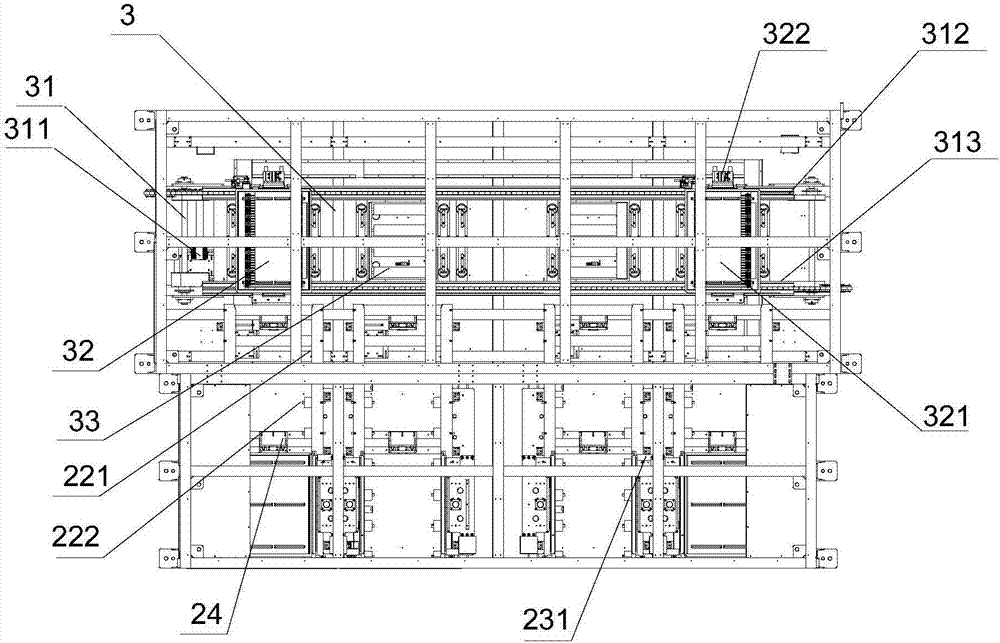

[0044] Such as Figure 1 to Figure 18 As shown: the automatic loading and unloading machine for soft-pack lithium batteries according to the present invention, including frame 1, pallet depalletizing and conveying unit 2, double-speed chain conveyor unit 3, pallet loading and unloading manipulator unit 4, and battery scanning and rotating unit 5. Defective battery unit 6, water truck loading and unloading manipulator unit 7, battery transfer water truck 8 and controller, pallet depalletizing and conveying unit 2, double-speed chain conveyor unit 3, pallet loading and unloading manipulator unit 4, battery The code scanning rotation unit 5, the bad battery unit 6, the water truck loading and unloading manipulator unit 7, the battery transfer water truck 8 and the controller are all installed on the frame, and each unit is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com