Light weight wall board production technology and equipment complex thereof

A complete set of equipment and light-weight wallboard technology, applied in the field of light-weight wallboard, can solve the problems of inconvenient automatic large-scale production, large production site requirements, and large site construction investment, etc., to reduce the production site area, enhance continuity, Quality stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

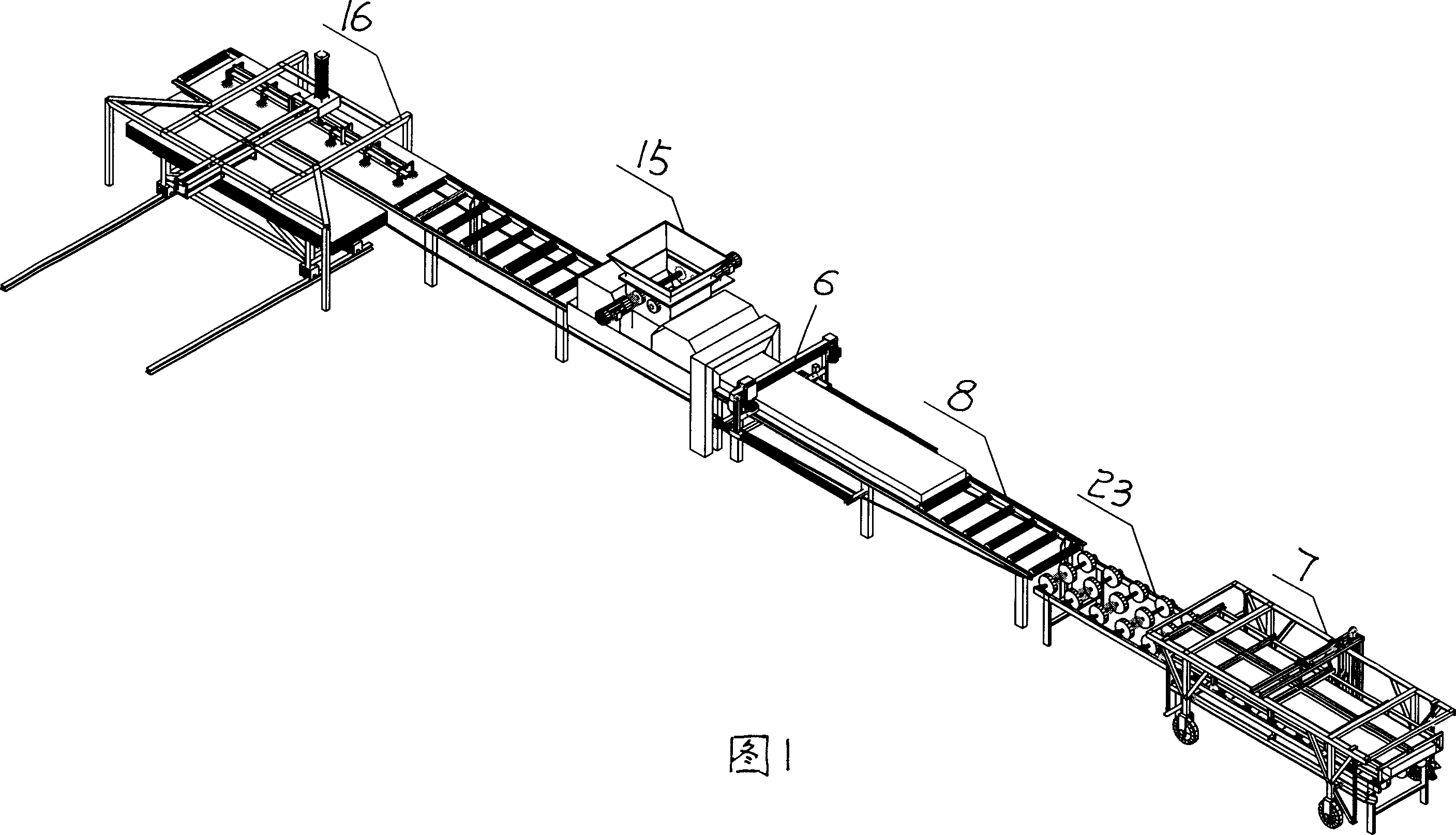

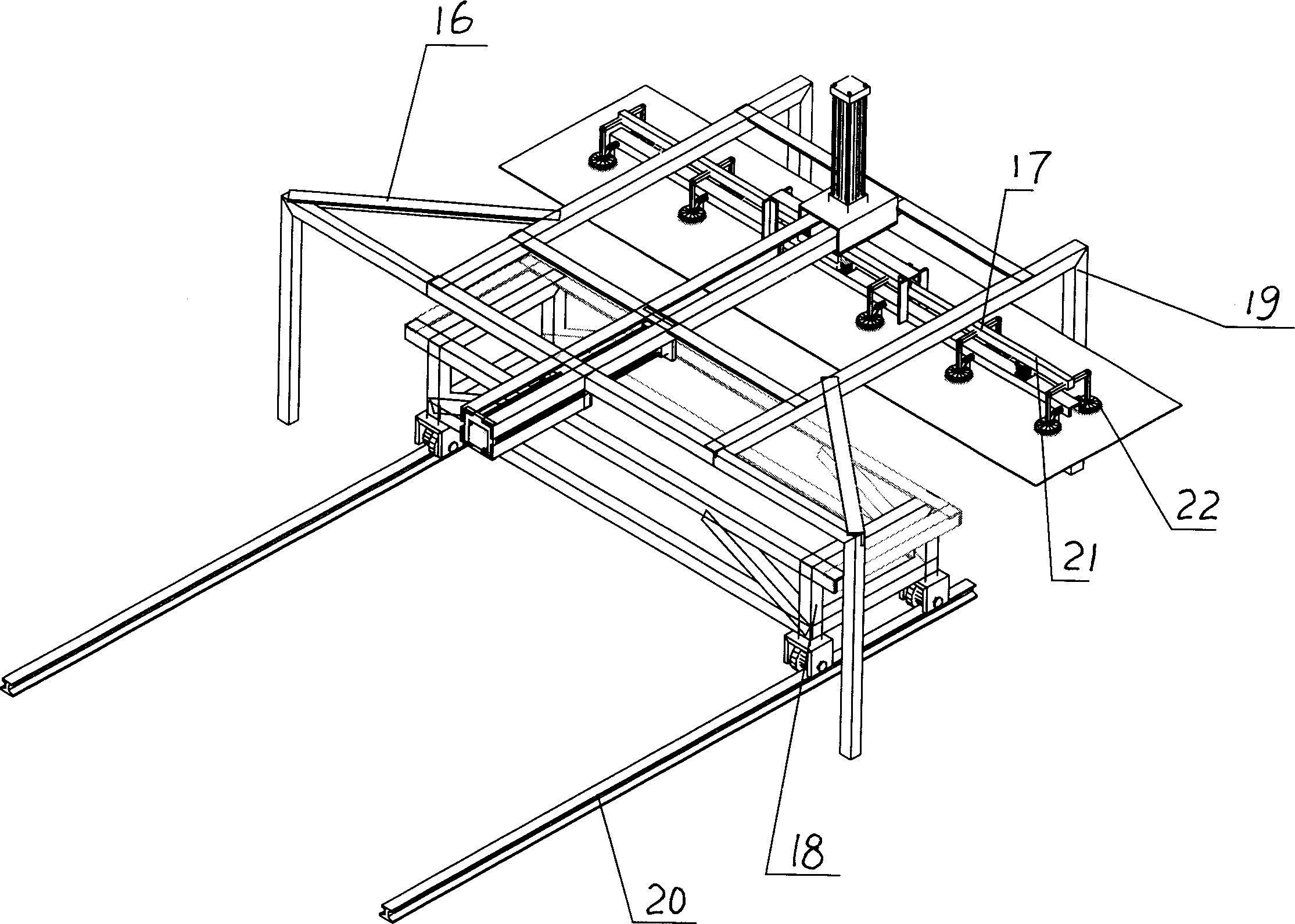

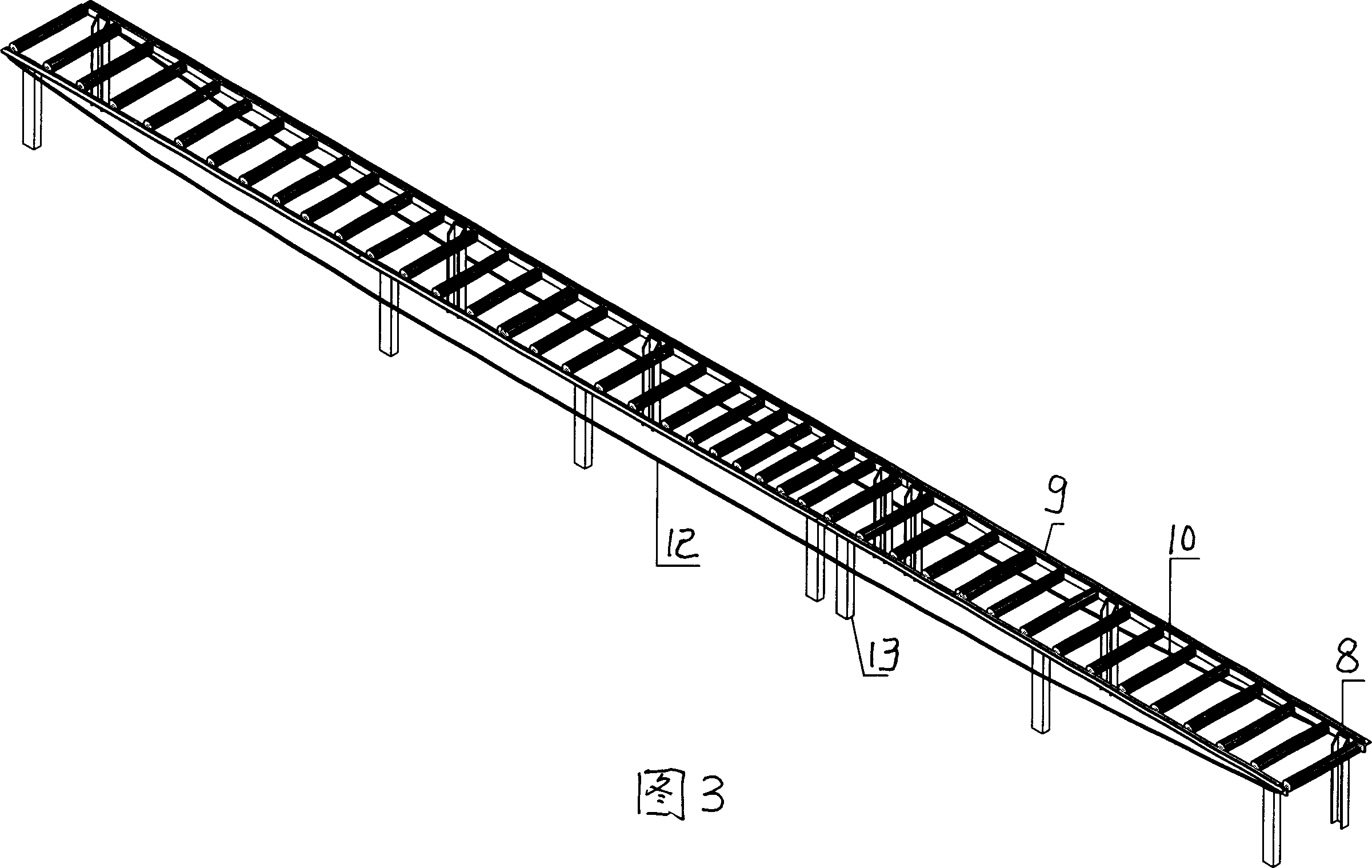

[0032] A kind of structure of the complete set of equipment for producing lightweight wallboard of the present invention is shown in Figure 1, figure 2 , Figure 3, Figure 4, Figure 5 Shown: Mainly consists of plate loading machine 16, screw vibrating extruder 15, chain conveyor 8, wheel conveyor 23, plate car 7, material mixing system, air compressor and air supply system, electrical control system Composition, the material mixing system provides a mixture of fly ash, slag, straw, cement, additives, and water for the entire production process; the air compressor system provides compressed air for the upper plate system; the electrical control system is responsible for the electrical control of the entire production line and related mechanical equipment.

[0033] The structural relationship of the following equipment included in the complete set of equipment is:

[0034] A, upper plate machine, upper plate machine 16 is made of flat sucker 17, carriage 18, frame 19, wherein ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com