Water-soluble quenching agent and preparation method thereof

A technology of water-soluble quenching agent and aqueous solution, applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of flammable environment, pollution, high price, etc., achieve the effect of small environmental pollution, overcome high price and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

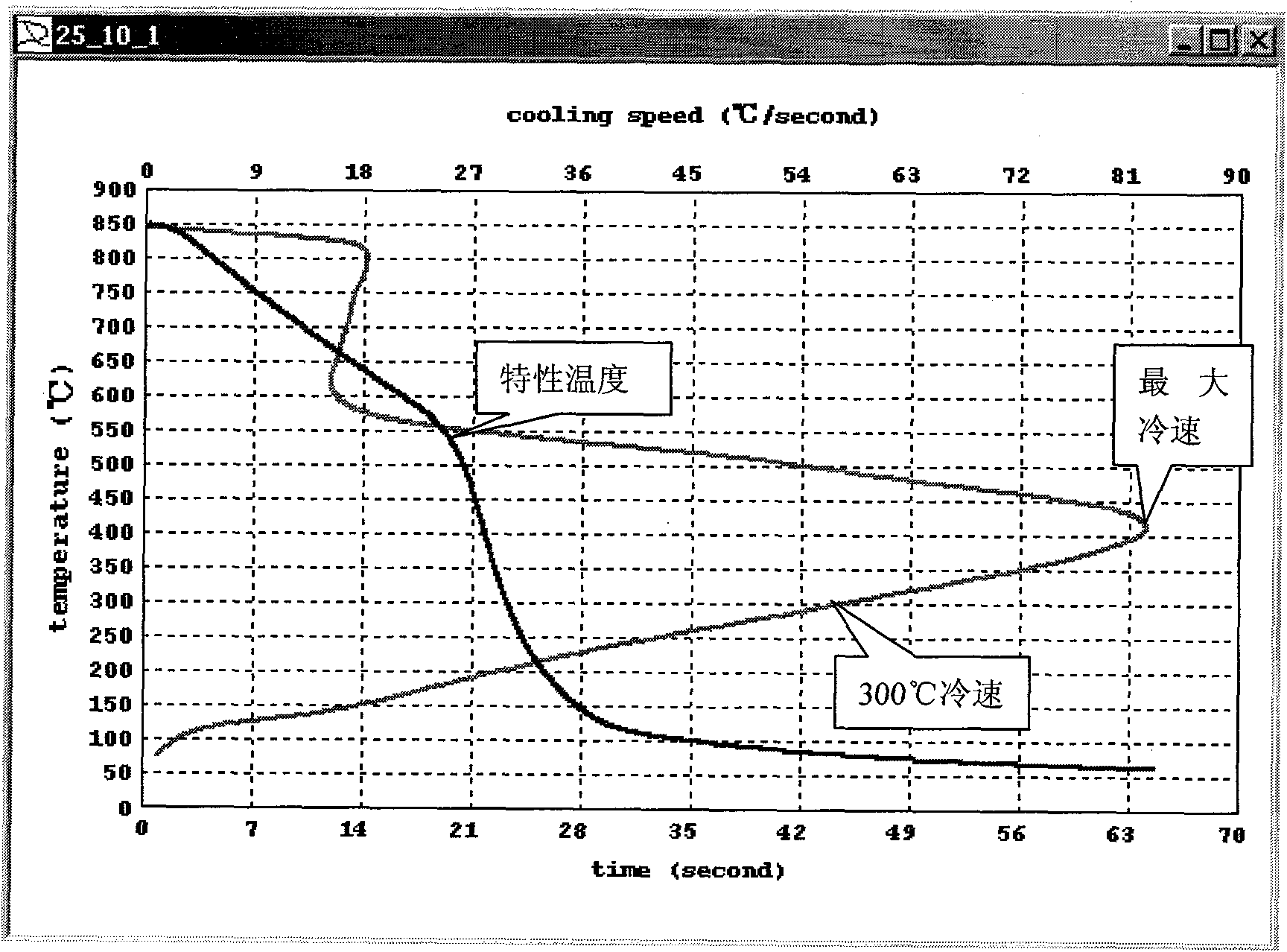

[0028] Heat 50ml of water to 70°C, add 5g of starch to the water under constant stirring, and stir evenly to form solution A; dissolve 0.5g of sodium hydroxide in 2.5ml of water to form solution B; Solution B was slowly added to solution A to gelatinize the starch, then water was added to 1L, and 5g boric acid was added to make a quenching agent with sodium hydroxide:starch=0.1:1 and a starch concentration of 0.5g / L. Compared with water, this quenching agent has lower characteristic temperature and reduced maximum cooling rate, which can reduce the thermal stress in the high temperature zone, and has almost no effect on the depth of the hardened layer. It is suitable for the quenching of parts with low hardenability and induction heating surfaces Hardened parts.

Embodiment 2

[0030] Heat 200ml of water to 70°C, add 25g of starch to the water under constant stirring, and stir evenly to make solution A; dissolve 2.5g of sodium hydroxide in 10ml of water to make solution B; make the solution under constant stirring B is slowly added to solution A to gelatinize the starch, then water is added to 1L, and 5g phenol is added to make a quenching agent with sodium hydroxide:starch=0.1:1 and a starch concentration of 25g / L. The cooling capacity of this quenching agent is smaller than that of oil, and it can be used for forging cooling instead of normalizing, which can refine the structure, or quenching of high alloy tool steel.

Embodiment 3

[0032] Heat 200ml of water to 30°C, add 25g of starch to the water under constant stirring and stir evenly to make solution A; dissolve 300g of sodium hydroxide in 600ml of water to make solution B; under constant stirring, make solution B Slowly add to solution A to gelatinize the starch, then add water to 1L, and then add 5ml of formaldehyde to make a quenching agent with sodium hydroxide:starch=12:1 and starch concentration of 25g / L. Compared with the quenching agent of Example 2, the low-temperature cooling rate of this quenching agent is basically unchanged, but the characteristic temperature is increased, the maximum cooling rate is increased, and the overall performance is close to the quenching oil. It can be quenched by most alloy steels.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com